Electronic component conveying device

A technology of electronic components and transmission devices, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of excessive force, waste of manpower, damage to electronic components, etc., and achieve the effect of soft turning, convenient and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

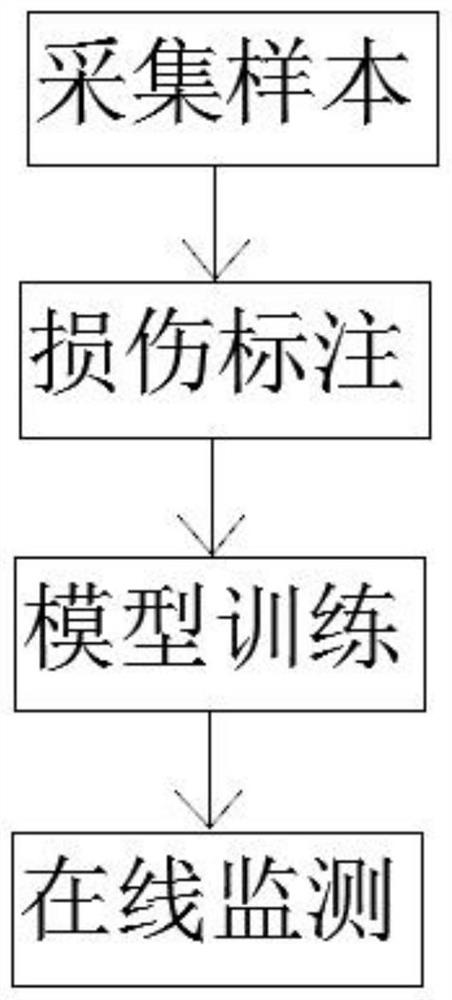

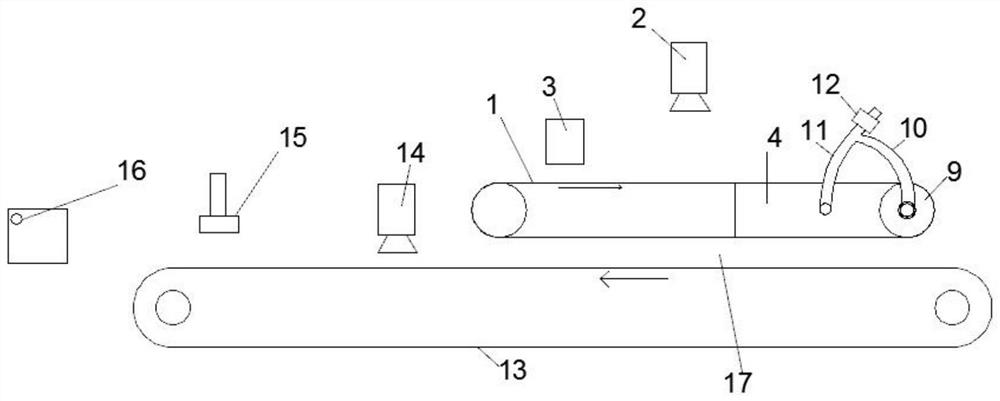

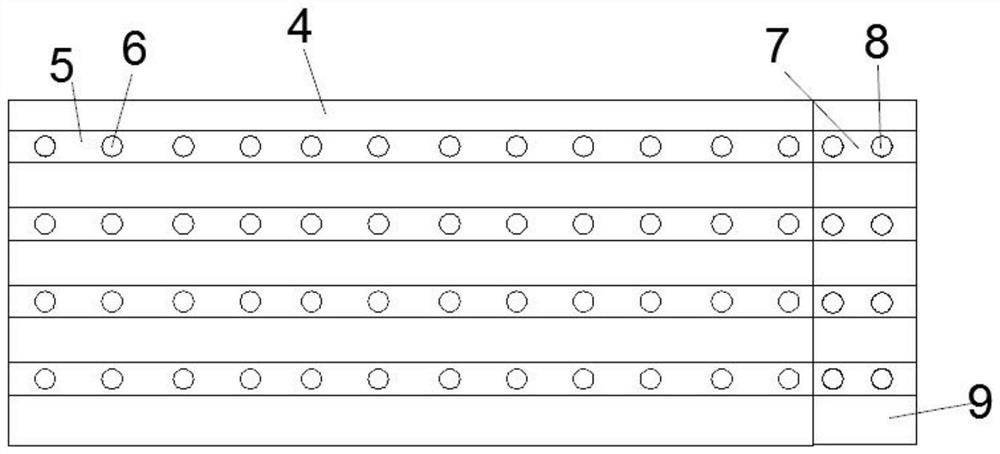

[0016] like figure 1 A method for inspecting electronic components based on machine vision includes the following steps: Step 1. Collect image samples of damage images on the surface of electronic components and image samples without damage to electronic components, and simultaneously collect ultrasonic waves corresponding to the image samples of damage on the surface of electronic components. Flaw detection signals and ultrasonic flaw detection signals corresponding to image samples without damage to electronic components;

[0017] Step 2, manually marking the damage type of the damage image on the surface of the electronic component, and obtaining a sample of the damage image on the surface of the electronic component after marking;

[0018] Step 3. Partially marked damage image samples on the surface of electronic components, image samples without damage to electronic components, and corresponding ultrasonic flaw detection signals are respectively used as positive sample se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com