Efficient tower body inner wall cleaning equipment for carbonating tower and carbonating system

A carbonation tower and cleaning equipment technology, applied in the field of soda ash industry, can solve the problems of slow production efficiency, no cleaning system, insufficient reaction, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

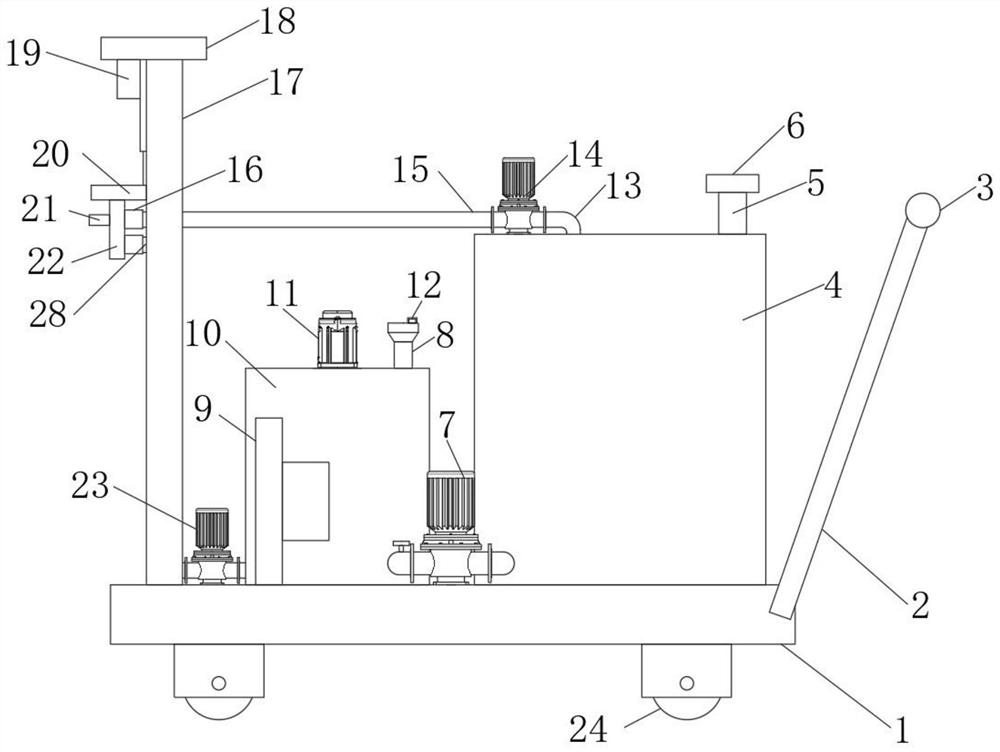

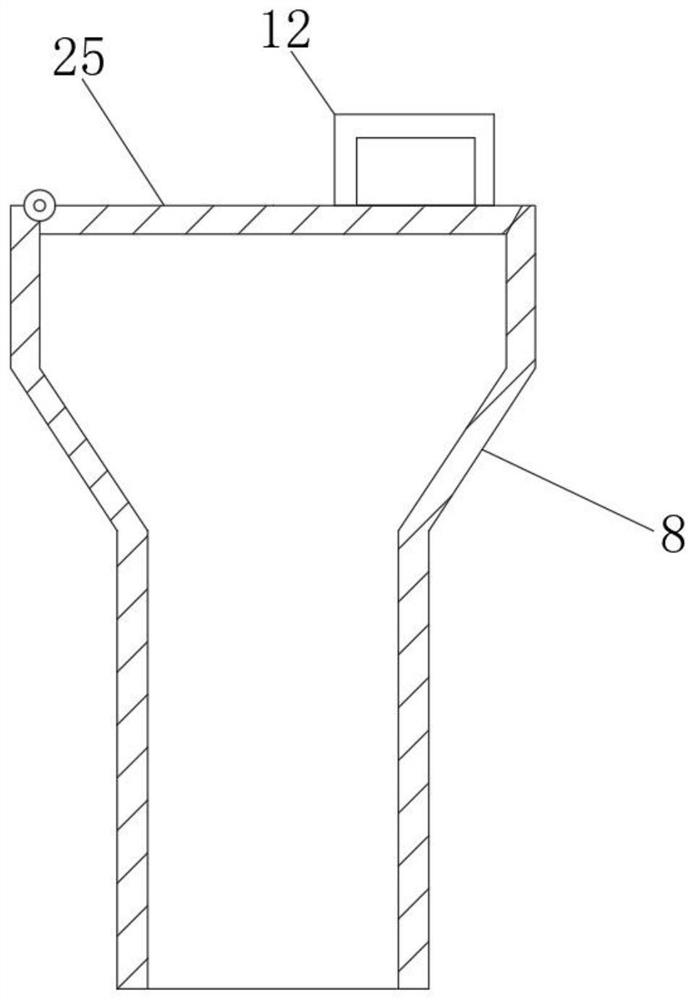

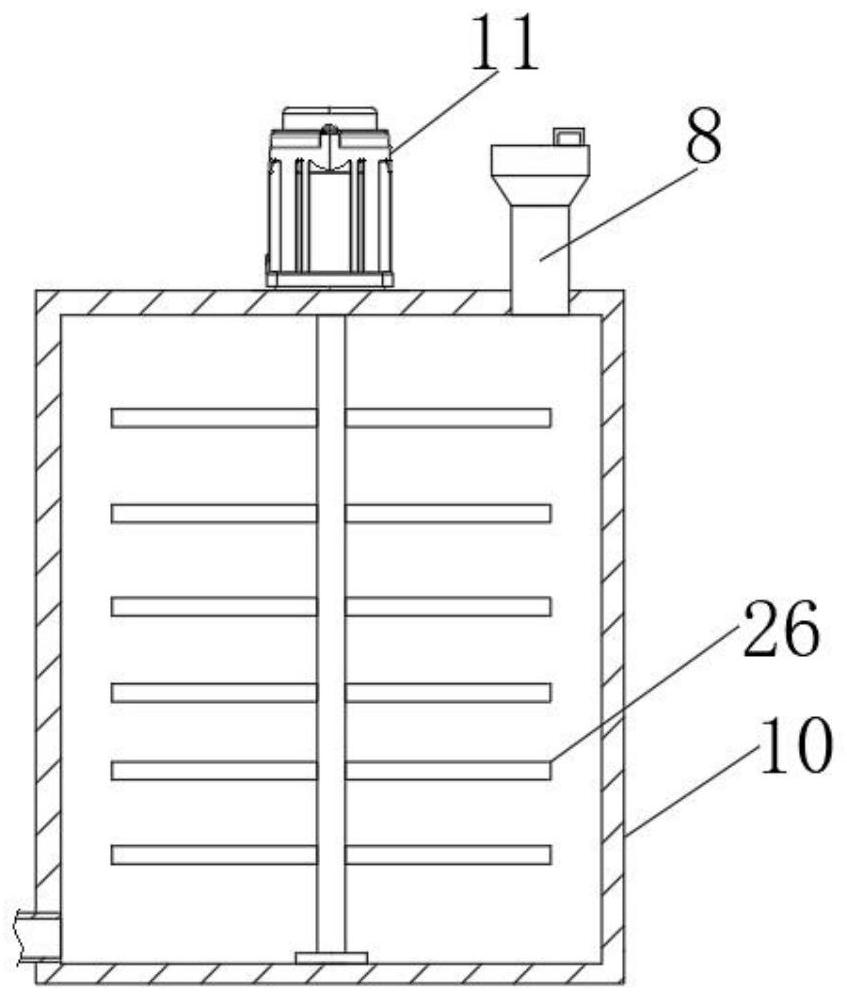

[0025] see Figure 1-4 , the present invention provides a technical solution: a carbonation tower and a high-efficiency cleaning equipment for the inner wall of the carbonation tower, including a bottom plate 1, the upper surface of the bottom plate 1 is welded with a liquid medicine tank 10, and the upper surface of the bottom plate 1 is located in the medicine One side of the liquid tank 10 is welded with a water tank 4, and the upper surface of the bottom plate 1 is welded symmetrically with two support columns 17, and the top of the two support columns 17 is welded with a horizontal plate 18, and the lower surface of the horizontal plate 18 is equipped with an electric push rod 19 , the inner sidewalls of the two support columns 17 are slidably connected with a sliding plate 20, the upper surface of the sliding plate 20 is welded with the piston rod of the electric push rod 19, the lower surface of the sliding plate 20 is welded with a third water pipe 22, the third water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com