Automatic hard sport spraying machine for machining nitrile rubber glove production ceramic hand mold

A technology for nitrile rubber and gloves, which is applied in the field of automatic hemp spraying machines for the production of nitrile rubber gloves for the production of ceramic hand molds, can solve problems such as being unsuitable for large-scale glove dotting operations, and that the outer surface of gloves cannot be uniformly dotted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

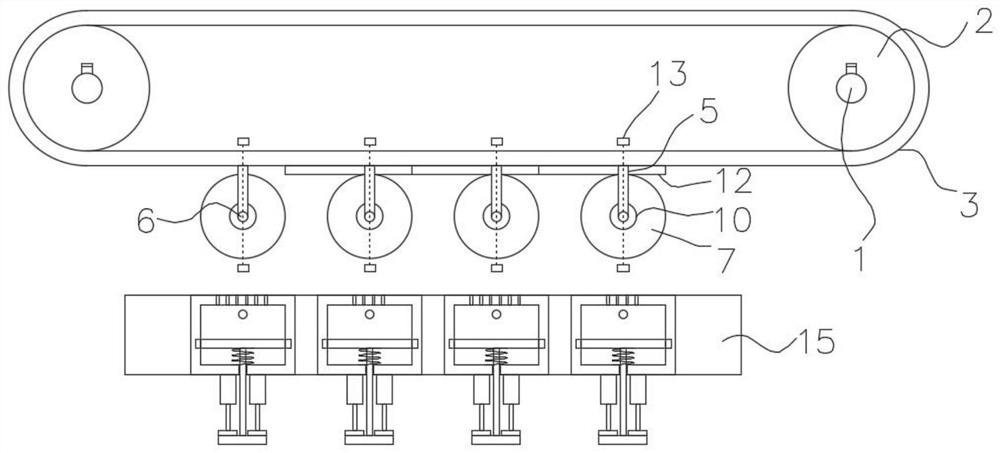

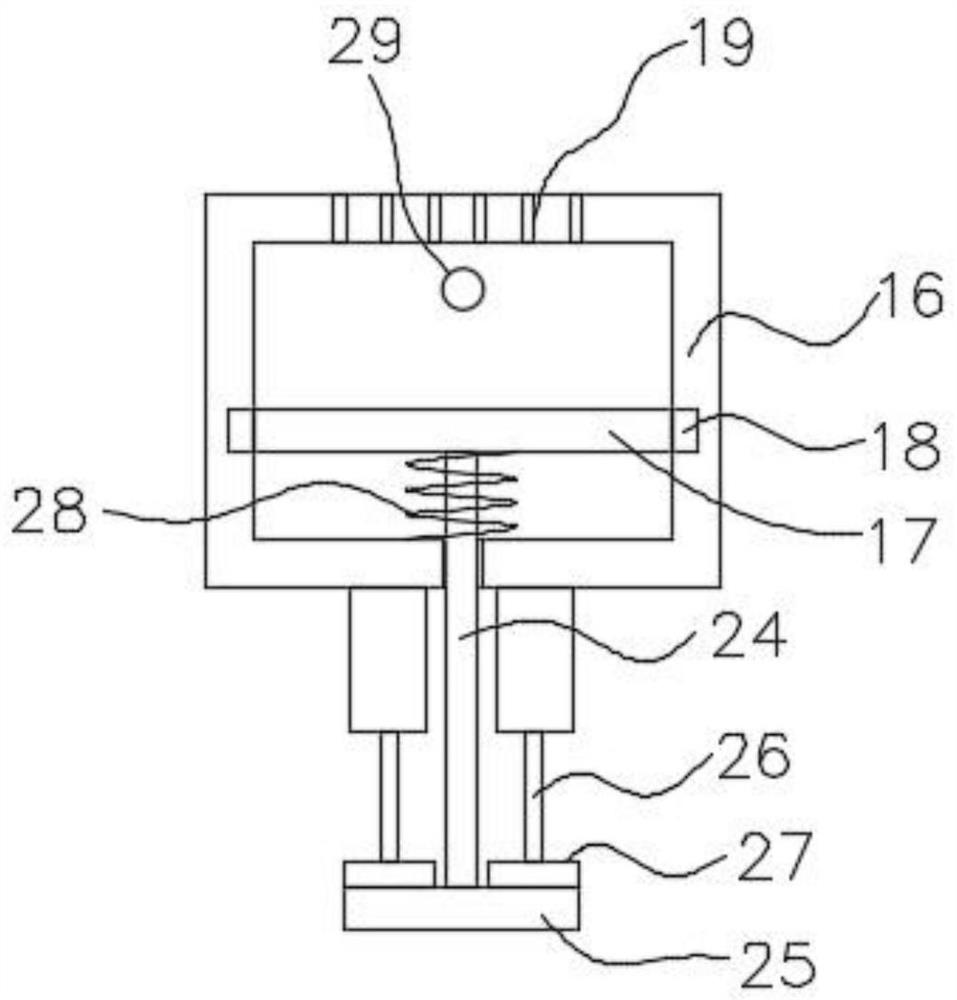

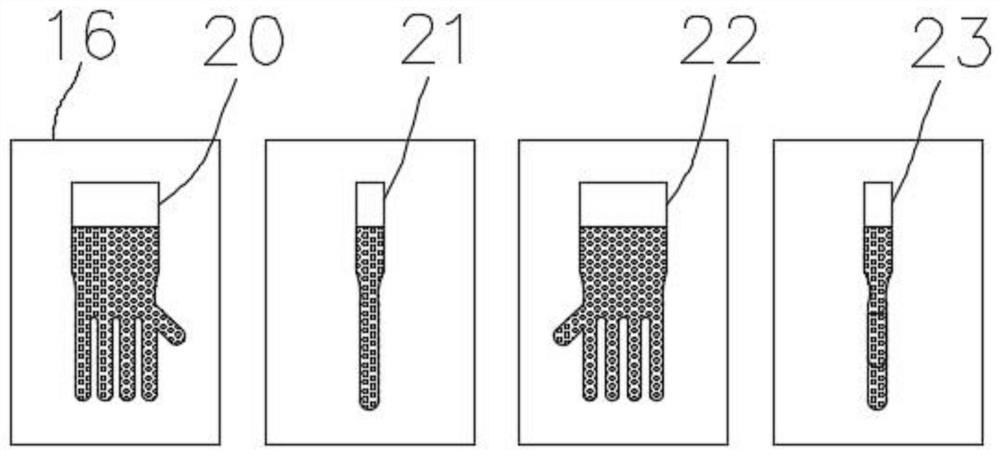

[0024] refer to Figure 1-6 , an automatic hemp spraying machine for the production of nitrile rubber gloves for ceramic hand mold processing, including two vertical transmission shafts 1, the two transmission shafts 1 are fixedly sleeved with sprockets 2 at corresponding positions, and are located on different transmission shafts The two sprockets 2 corresponding to the position on the 1 are meshed together with a chain 3, and the upper end of one of the transmission shafts 1 is fixedly connected with a transmission motor 4, and the transmission motor 4 drives the chain 3 through the transmission shaft 1 and the sprocket 2 for transmission. The chain 3 is evenly welded and fixed with a support rod 5, and the ends of the two support rods 5 away from the chain 3 are jointly welded and fixed with a vertical rod 6, the lower end of the vertical rod 6 is rotatably connected with a gear 7, and the lower end of the gear 7 is coaxially fixedly connected with a bottom The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com