Transient starting electromagnetic valve based on remote control and electromagnetic valve starting method

A remote control and solenoid valve technology, which is applied in the field of solenoid valve startup and transient startup solenoid valve, can solve the problems of equipment operation stability, heat generation, sealing, and overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

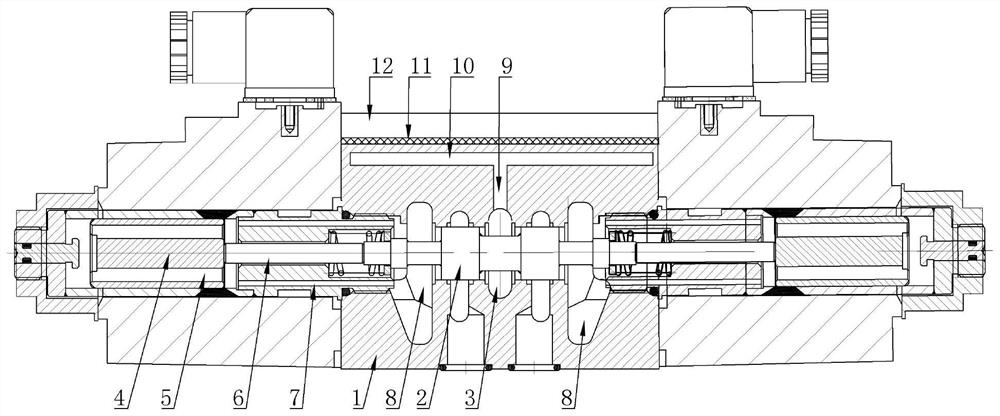

[0025] Embodiment 1: A transient start solenoid valve based on remote control, see Figure 1 to Figure 3 .

[0026] It includes a valve body 1, an electromagnet 13 located on the left and right sides of the valve body 1, a valve core 2 located in the valve body 1, and an armature 4 respectively located in the two electromagnets 13. A guide body 7 is provided in the channel, and a guide hole is provided in the guide body. The front end of the valve core 2 is located in the guide hole and is supported by the guide hole. A push rod 6 is also provided in the guide hole. One end of the push rod 6 is against the end of the valve core 2, and the other end of the push rod 6 is in contact with the end of the armature. The two electromagnets 13 are respectively provided with coils, and the valve body is provided with There are an oil inlet 2 and an oil outlet 8, and the oil outlet 8 is located on the left and right sides of the valve body.

[0027] The above-mentioned structure is the...

Embodiment 2

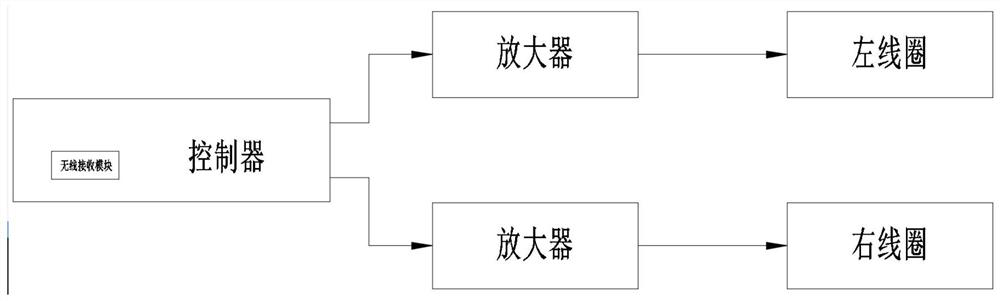

[0035] Embodiment 2, a method for starting a solenoid valve, see image 3 , this method is applied to the electromagnetic valve described in embodiment 1, and it comprises the steps:

[0036] (1) The trigger signal is transmitted to the controller in the form of wireless or wired, and the controller starts the amplifier to increase the starting current;

[0037] (2) The amplifier sends instantaneous high current to the coil of the solenoid valve to start the armature action in an instantaneous and high current manner and drive the valve core to move.

[0038] To sum up, this design starts the movement of the spool transiently. Compared with the smooth movement of the existing spool, the movement time of the spool in this design is greatly reduced. Through this transient start method, the movement of the spool can be greatly saved. Time, reduce the action time of the coil and the electromagnet, and reduce the heat energy generated when the spool is reversing during frequent ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com