Temperature detection system for inner chamber of universal joint and detection method thereof

A detection system and universal joint technology, applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve problems such as inaccurate temperature monitoring data, improve sensitivity, and increase heat conduction The area and the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The following is attached Figure 1-3 The application is described in further detail.

[0039] The embodiment of the present application discloses a universal joint inner cavity temperature detection system and a detection method thereof.

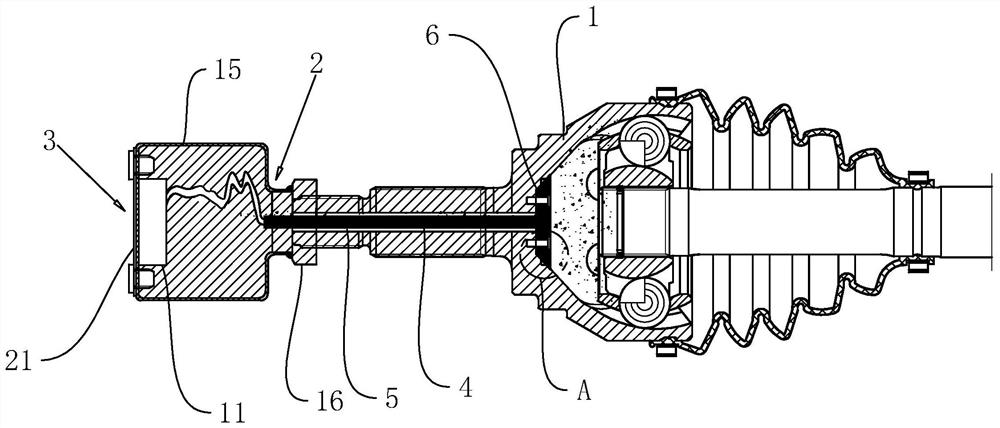

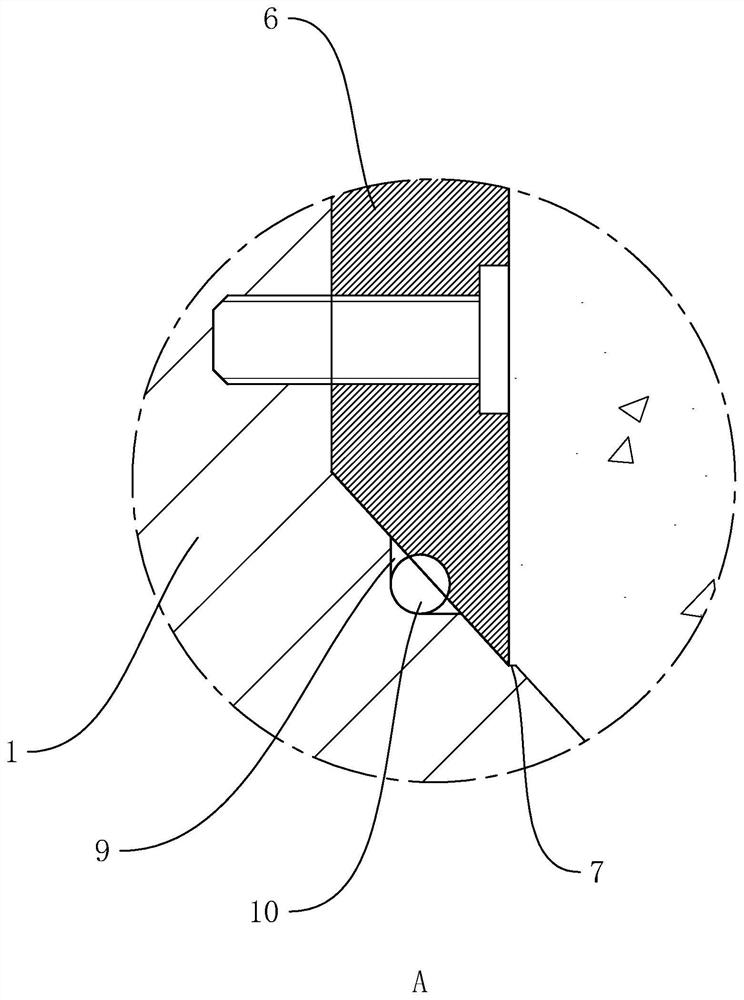

[0040] refer to figure 1 , a universal joint inner cavity temperature detection system, including a sensor 2 arranged on a ball cage type universal joint 1, the sensor 2 includes a data processing device 3 and a probe rod 4, a thermistor is integrally arranged in the probe rod 4, A through hole 5 is opened on one end surface of the shaft of the ball cage type universal joint 1 , the through hole 5 communicates with the inner cavity of the ball cage type universal joint 1 , and the insertion rod is inserted into the inner cavity of the through hole 5 .

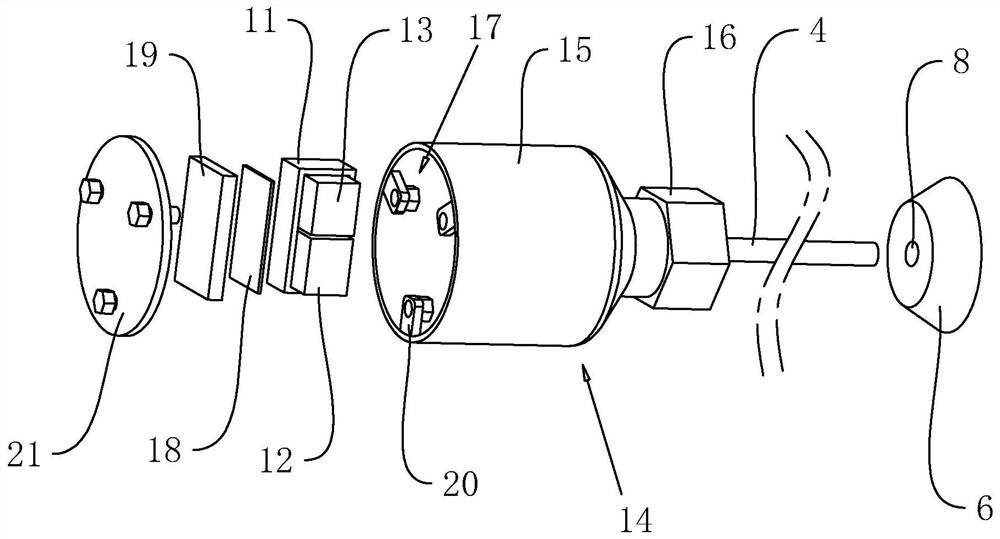

[0041] refer to figure 2 , the data processing device 3 comprises an installation shell 11, a data processor 12 and a wireless bluetooth transmitter 13, and the data processor 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com