Rotor punching sheet, rotor iron core, motor and compressor

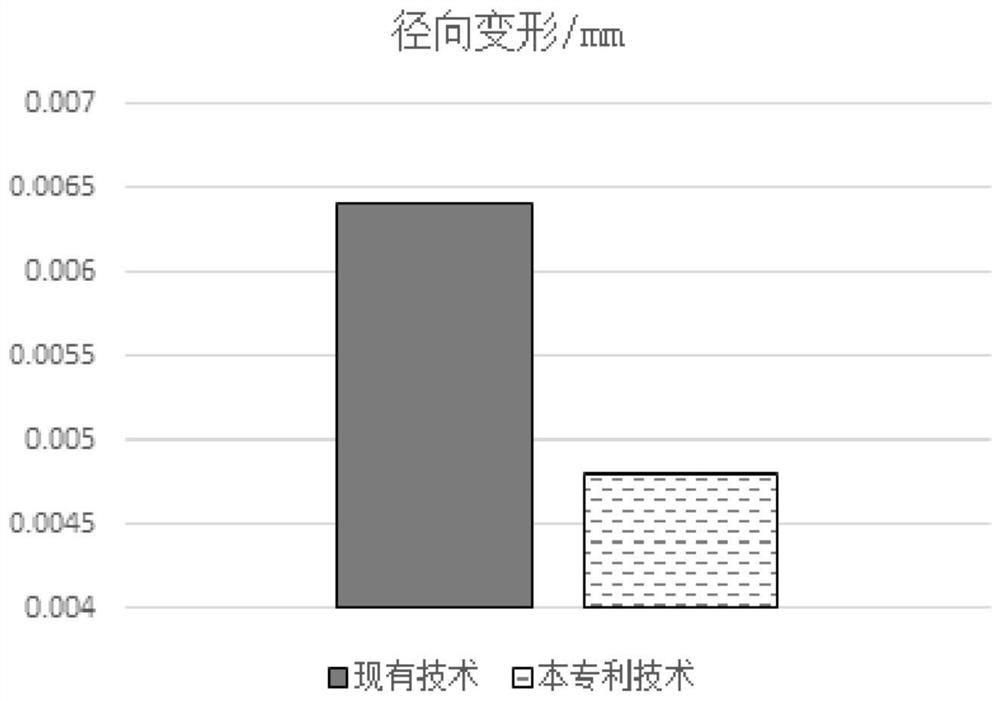

A technology of rotor punching and rotor core, which is applied in the field of compressors, can solve the problems that the magnetic isolation bridge of the rotor bears a large force, and the magnetic isolation bridge cannot meet the structural strength requirements of the rotor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

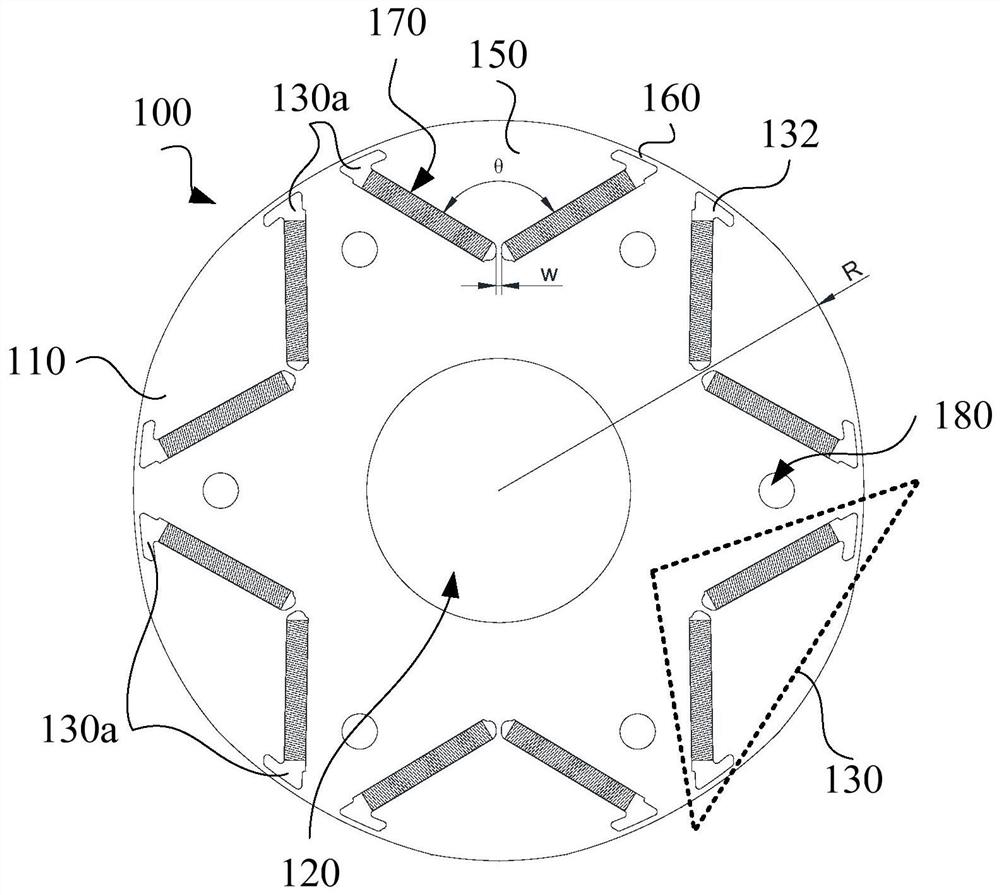

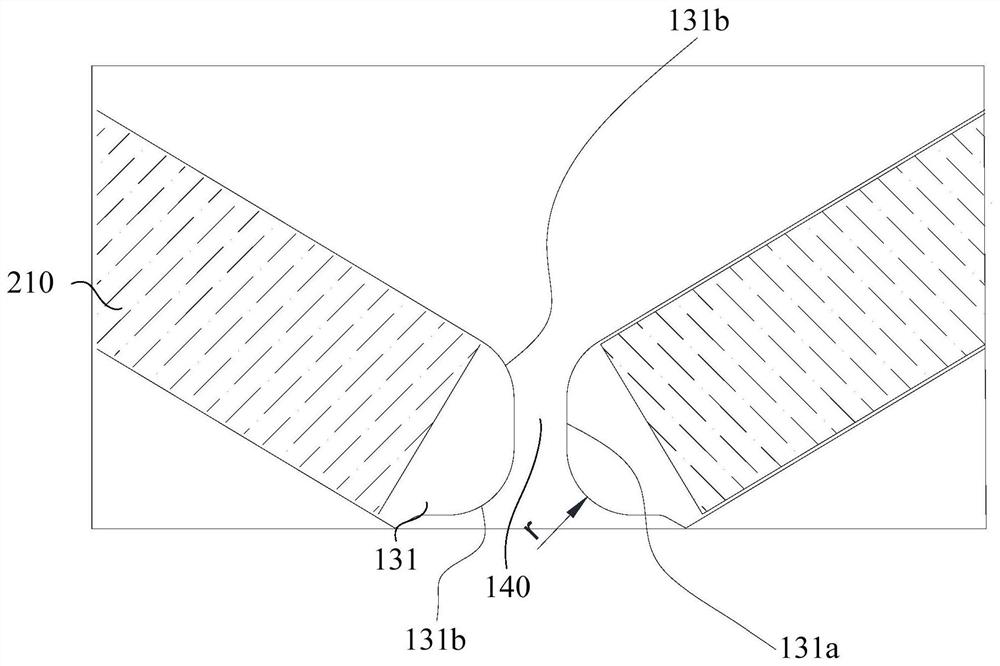

[0066] According to the first aspect of the present invention, such as figure 1 and figure 2 As shown, a rotor punch 100 is provided, which includes a punch body 110 , a shaft hole 120 and a plurality of mounting parts 130 , wherein the shaft hole 120 is disposed on the punch body 110 . A plurality of mounting portions 130 are disposed on the die body 110 around the shaft hole 120 . Each mounting part 130 in the plurality of mounting parts 130 includes two magnet slots 130a, and each magnet slot 130a in the two magnet slots 130a includes a first slot end 131 close to the shaft hole 120, wherein the first slot end 131 includes a straight The groove segment 131a and the arc groove segment 131b connected to the two ends of the straight groove segment 131a.

[0067] The rotor punch 100 provided by the present invention includes a punch body 110 , a shaft hole 120 and a plurality of mounting parts 130 . The shaft hole 120 is opened on the punching body 110, and the punching bod...

Embodiment 2

[0081] On the basis of the foregoing examples, as figure 1 and figure 2 As shown, in this embodiment, a specific description is made for the second slot end 132 of the magnet slot 130a away from the shaft hole 120. Further, the magnet slot 130a includes the second slot end 132 away from the shaft hole 120, and the two first slot ends The distance between 131 is smaller than the distance between the two second groove ends 132, and the second groove ends 132 extend toward the interior of the installation area 150, and the part of the punching between the second groove ends 132 and the outer periphery of the punch body 110 The sheet body 110 constitutes a second magnetic isolation bridge 160 .

[0082] In this embodiment, the magnet slot 130 a further includes a second slot end 132 away from the shaft hole 120 , and the second slot end 132 and the first slot end 131 are opposite ends of the magnet slot 130 a. Since the number of magnet slots 130a is two, the number of second s...

Embodiment 3

[0086] According to a second aspect of the present invention, a rotor core is provided, including the rotor punch 100 provided in any one of the above-mentioned embodiments.

[0087] The rotor core provided by the present invention includes the rotor punch 100 provided by any of the above-mentioned designs, so it has all the beneficial effects of the rotor punch 100 , which will not be repeated here.

[0088] The rotor punch 100 provided by the present invention includes a punch body 110 , a shaft hole 120 and a plurality of mounting parts 130 . The shaft hole 120 is opened on the punching body 110, and the punching body 110 is made of silicon steel. Among them, silicon steel refers to silicon alloy steel with a silicon content of 1.0% to 4.5% and a carbon content of less than 0.08%. Silicon steel has the characteristics of high magnetic permeability, low coercive force, and large resistivity, so the hysteresis loss and eddy current loss are relatively small. The shaft hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com