Slip casting process for closestool blank and slip casting device

A technology of grouting molding and embryo body, which is applied in ceramic molding machines, manufacturing tools, die-casting molds, etc., can solve the problems of low yield, poor mold removal operability, and labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

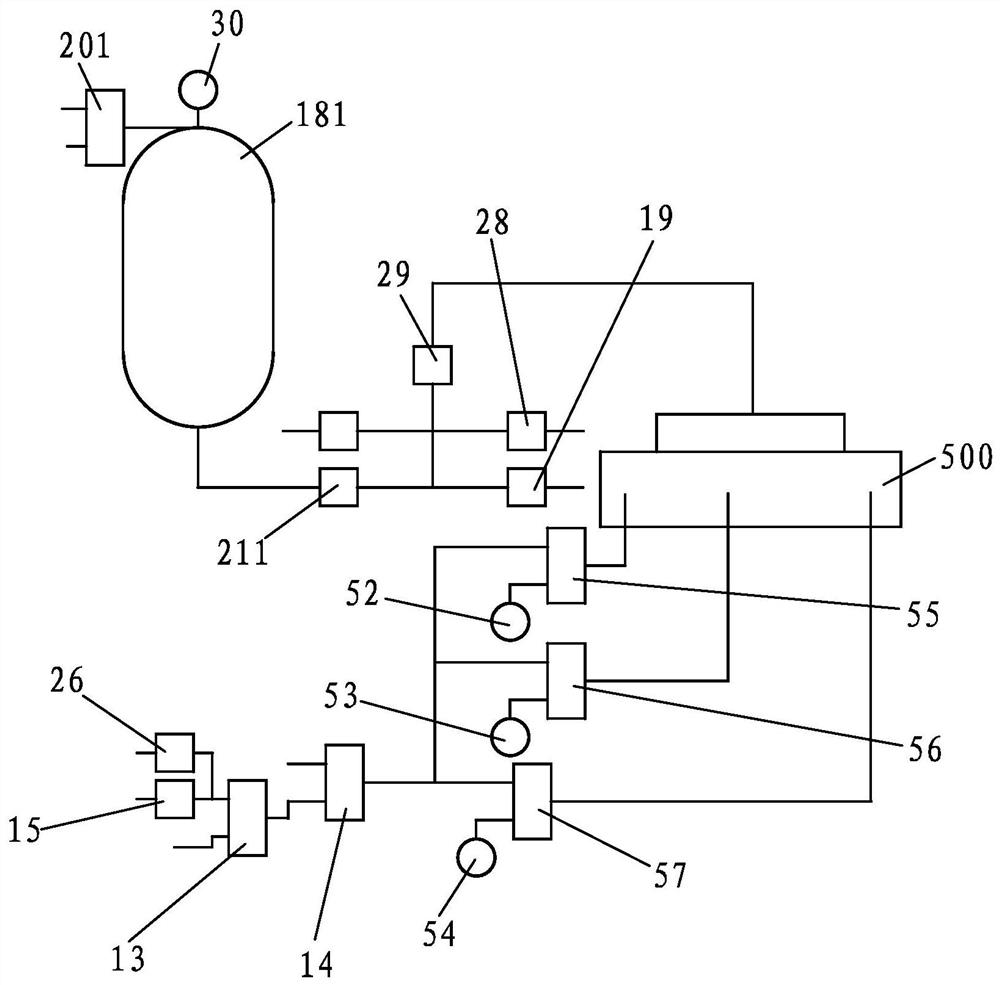

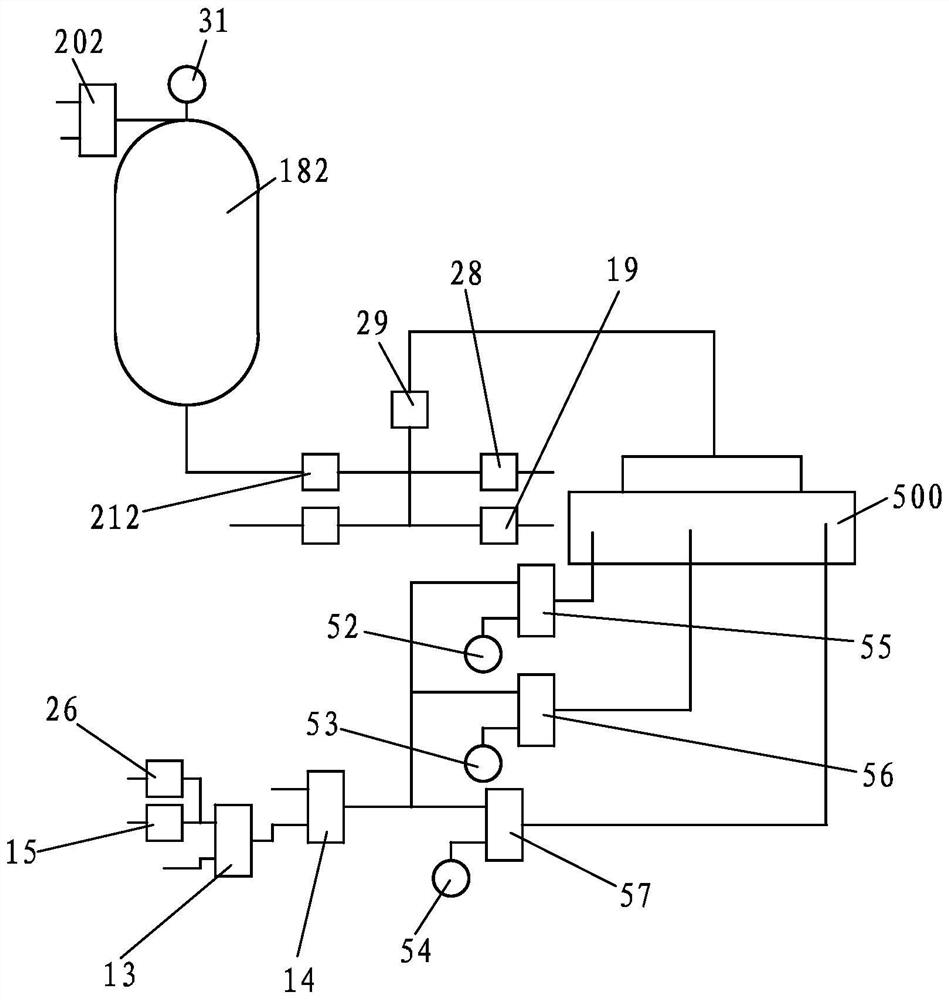

[0071] A kind of grouting molding process of toilet embryo body of the present invention, this grouting molding process comprises:

[0072] S1. Carry out low-pressure grouting into the mold cavity where the mold is clamped and locked. During the low-pressure grouting process, keep the natural air passages of the mold cavity and the mold walls of the left mold, right mold, rear mold, upper mold, and lower mold open. ;After the low-pressure grouting is finished, close the natural air path of the mold cavity;

[0073] S2. Carry out high-pressure grouting in the mold cavity. During the high-pressure grouting process, keep the natural air passages of the mold walls of the left mold, right mold, rear mold, upper mold, and lower mold open; after the high-pressure grouting is completed, close the left The natural gas path of the mold wall of the mold, right mold, rear mold, upper mold and lower mold;

[0074] S3. Open the blowing air circuit and the pulp discharge pipeline of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com