On-line scrubbing device for solar cell screen printing plate

A technology of screen printing and scrubbing device, applied in printing, printing machines, general parts of printing machinery, etc. and other problems, to achieve the effect of reducing contact, reducing human injury, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

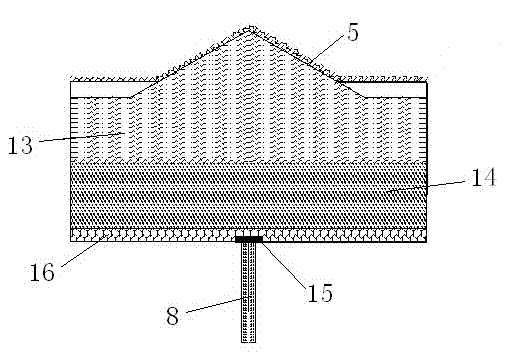

[0027] The perforated scraper 13 is elongated and has one or more blades. The perforated scraper 13 has holes perpendicular to the outer surface. The perforated scraper 13 is made of soft polyurethane rubber or fluorinated rubber. The hole scraper 13 bottom is installed in the organic solvent tank 6, and can move up and down along the organic solvent tank 6 inwalls, and the scraper with holes 13 surfaces is covered with flannelette 5.

[0028] There is a movable baffle 16 at the inner bottom of the organic solvent tank 6 , and the movable baffle 16 can move up and down along the inner wall of the organic solvent tank 6 . In the organic solvent tank 6, a sponge 14 is placed between the movable baffle 16 and the scraper 13 with holes, which has the function of absorbing the organic solvent and buffering the pressure. The organic solvent contained in the organic solvent tank 6 is alcohol, which can automatically supply alcohol according to the pressure of flannelette 5 and printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com