An unmanned vehicle wheel hub motor driving control system

An in-wheel motor and control system technology, which is applied in the field of vehicle engineering, can solve the problems of being unable to meet the performance requirements of light-duty high-motor vehicles, unable to apply light-duty high-motor vehicles, unable to meet the requirements of light-duty motor vehicles, etc., so as to improve off-road mobility performance and integration. High and low impact on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

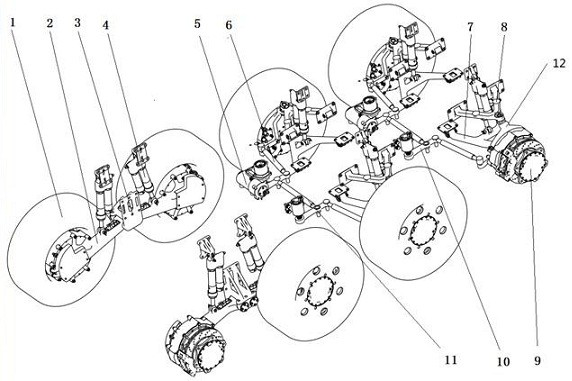

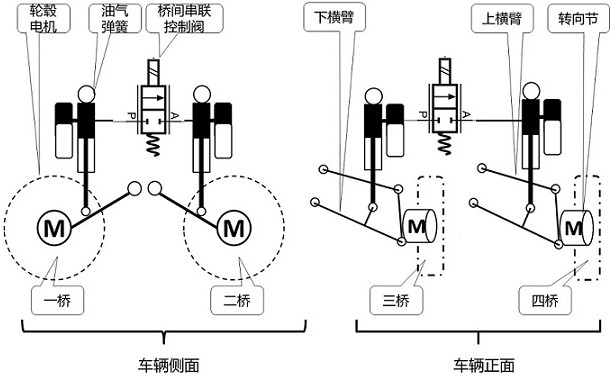

[0046] Figure 1-2 A high-mobility drive and control system for wheel hub motors of unmanned vehicles is shown. This system is especially suitable for light and ultra-high motor vehicles, and preferably requires an average off-road speed of 40 km / h; the maximum climbing angle is not less than 35°; the maximum The slope of the rolling driving is not less than 25°; the width of the trench is not less than 1.4 meters; the height of the vertical obstacles is not less than 0.9 meters.

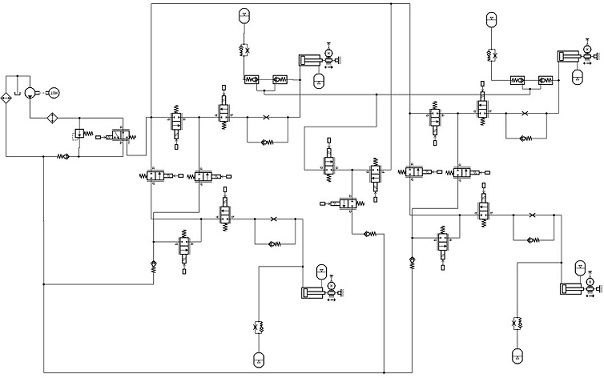

[0047] Such as figure 1 As shown, the present invention provides an unmanned vehicle hub motor driving and control system. The driving system adopts an 8×8 independent oil-pneumatic spring suspension to match the hub motor distributed drive technology scheme, and the first and second bridges are single trailing arm bridges. , the third and fourth bridges are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com