Closed fluid circulation system and its expansion control method

A technology of liquid circulation and circulation system, which can be used in heating systems, hot water central heating systems, heating methods, etc., and can solve problems such as labor and humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

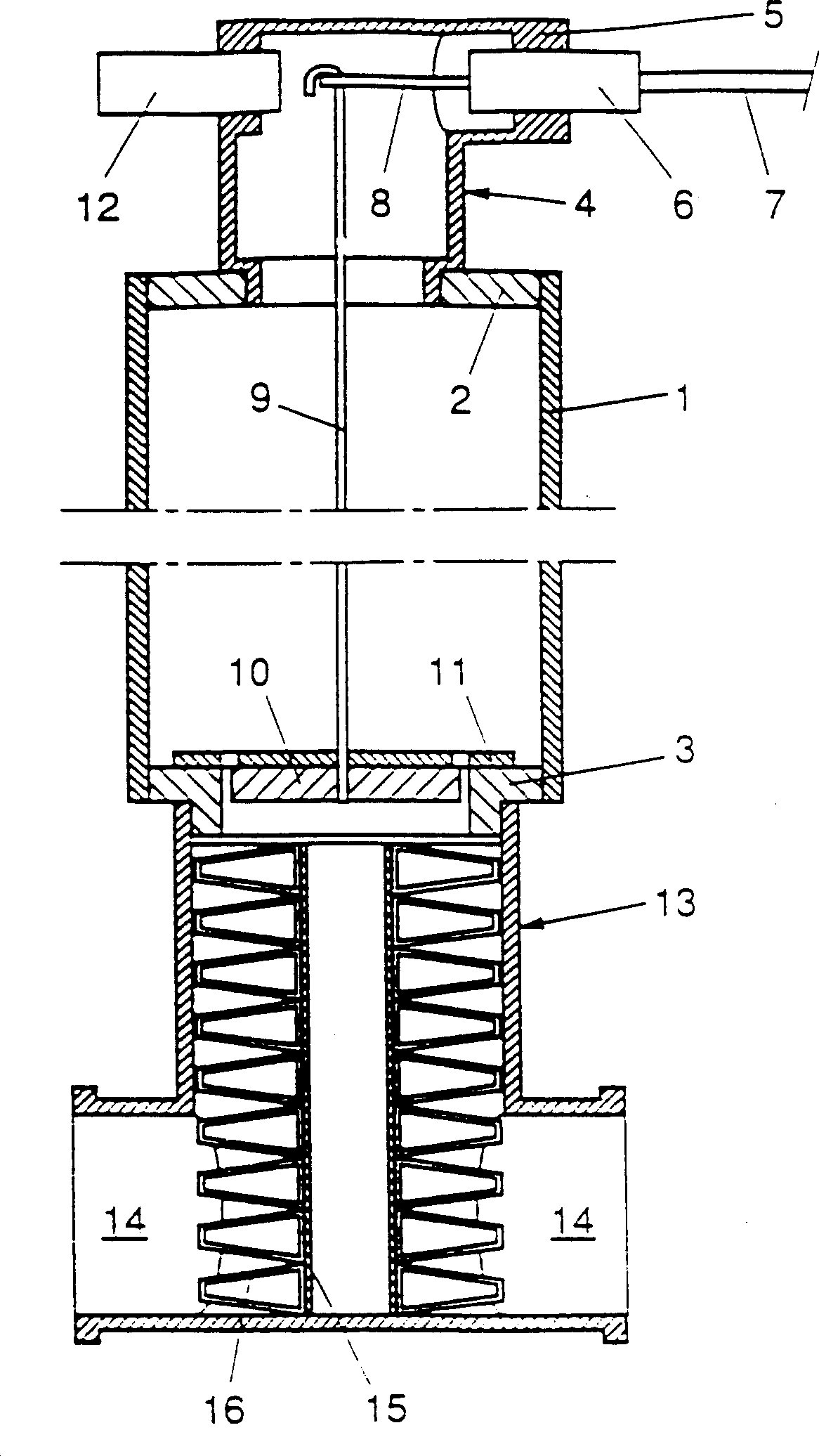

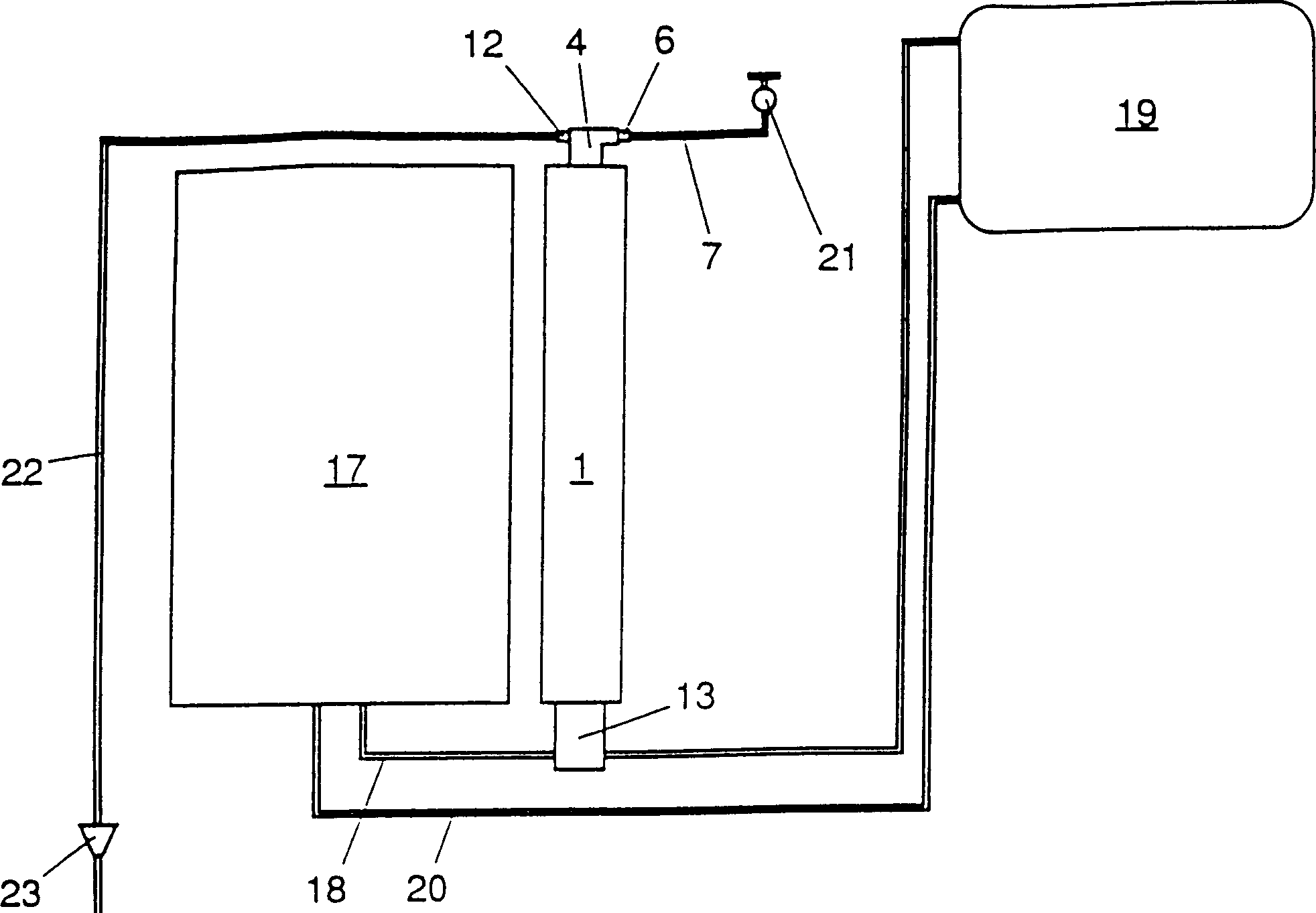

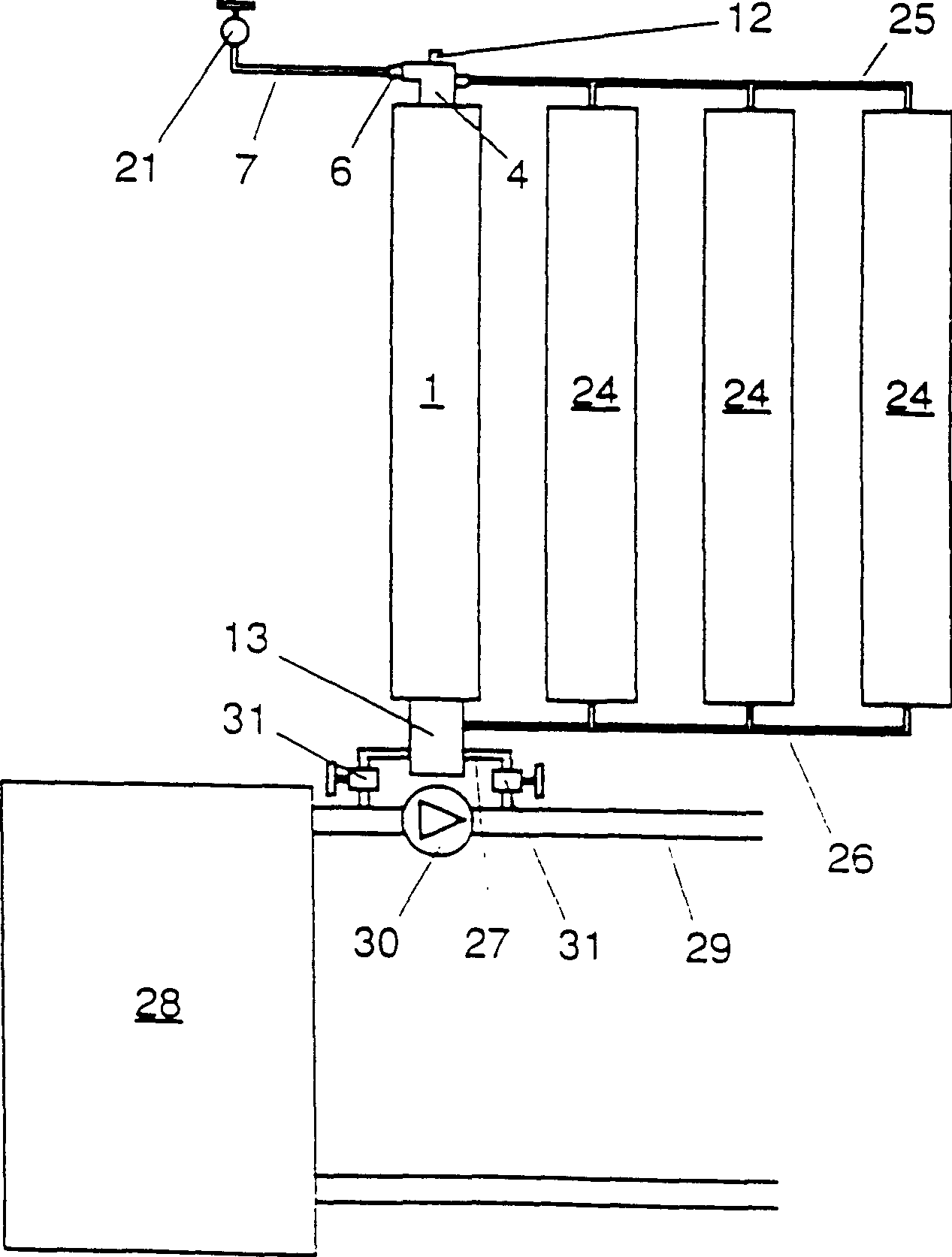

[0021] figure 1 The system shown comprises a cylindrical housing 1 with a top cover 2 and a bottom cover 3, the volume of which is greater than the total possible liquid expansion of a closed circulation system.

[0022] A cylindrical head 4 with a short pipe 5 is installed on the top cover 2, and the short pipe 5 has a valve 6, one end of which is connected with the water pipe 7, and the other end is connected with a control lever 8 that can be turned downward to open the valve 6 . A float bar 9 is hung on the end of the control rod 8 away from the valve 6, and the float bar 9 is connected with the float located below the perforated plate 11, and the float bar 9 can slide freely in the hole of the perforated plate. The head 4 also has an exhaust valve 12 for overpressure maintenance.

[0023] The T-shaped pipe fitting 13 is connected on the bottom cover 3, and its short pipe 14 is connected into a closed liquid circulation system (not shown in the figure) in a straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com