Preparation method capable of increasing friction force of conveyor belt

A conveyor belt and friction technology, which is applied in the preparation field of increasing the friction force of the conveyor belt, can solve the problems of reducing work efficiency, increasing labor intensity, and economic loss of goods, so as to improve production efficiency, high processing efficiency, and reduce labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

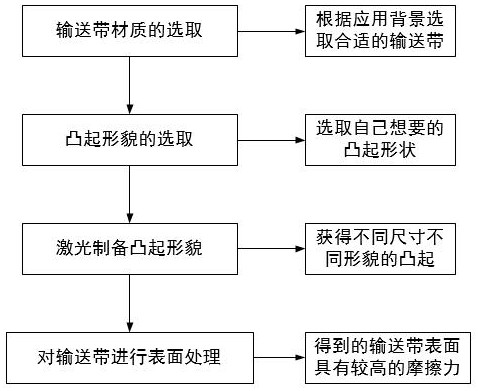

Method used

Image

Examples

Embodiment Construction

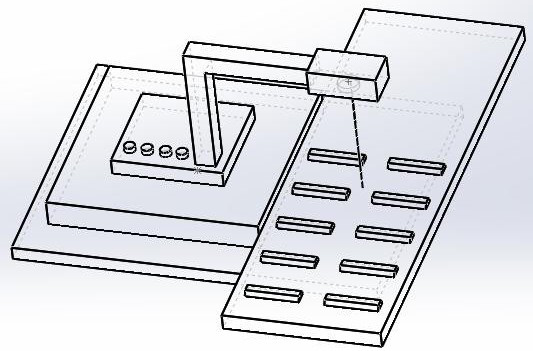

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In order to make the features, advantages and application background of the present invention clearer and easier to understand, the present invention will be further described through specific embodiments.

[0022] In the present invention, taking the silica gel conveyor belt made of silica gel as an example, protrusions of various shapes are prepared on its surface by means of laser processing, so as to increase the friction force on the surface of the conveyor belt.

[0023] Silica gel is a highly active adsorption material, which is an amorphous substance, insoluble in water and any solvent, non-toxic, tasteless, stable in chemical properties, and does not react with any substance except strong alkali and hydrofluoric acid.

[0024] Silicone conveyor belt is made of high-temperature-resistant, anti-corrosion, fire-proof and flame-retardant high-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com