Compressor system and air-conditioner

A compressor system and compressor technology, applied in the field of compressors, can solve the problems of increased pipeline stress, increased vibration of the pipeline system, and large vibration and noise of a horizontal double-cylinder rotor compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

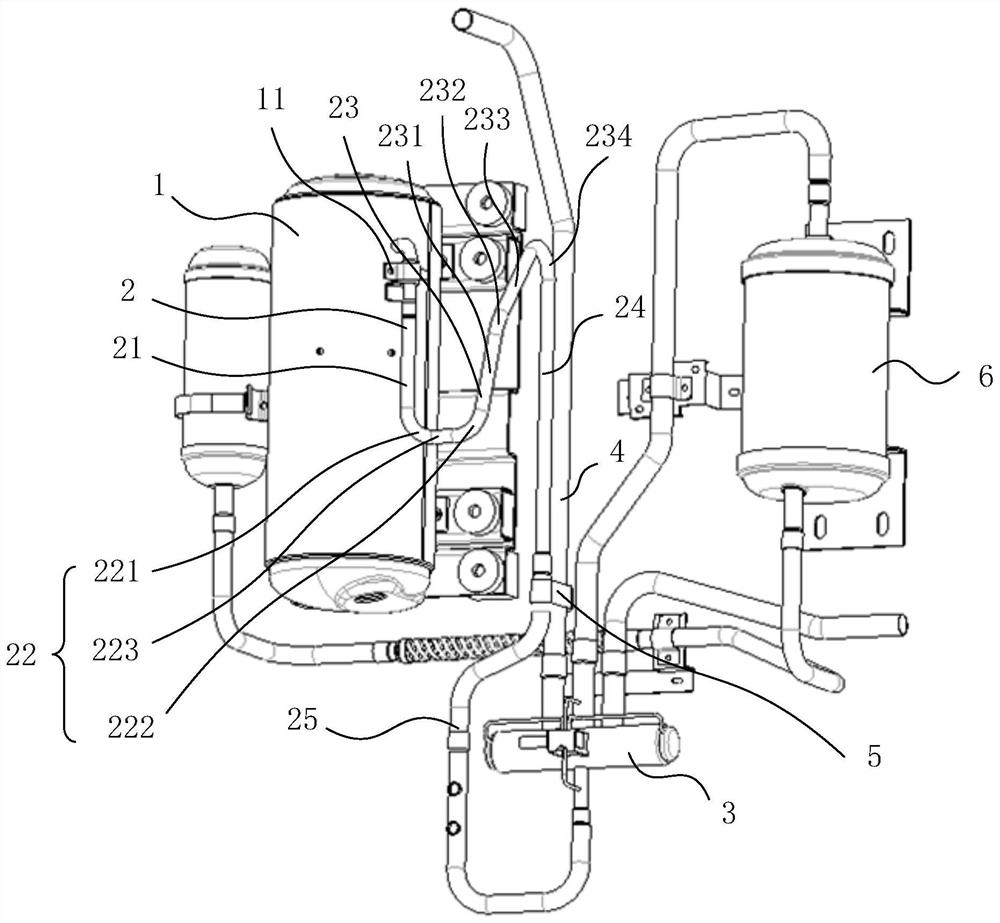

[0077] The exhaust pipe 2 includes a first pipe section 21 connected in sequence, a first bent pipe section 221 , a first straight pipe section 223 and a second bent pipe section 222 in the second pipe section 22 , and a second straight pipe section 231 in the third pipe section 23 , the third bent pipe section 232 , the third straight pipe section 233 and the fourth bent pipe section 234 , and the fourth pipe section 24 .

[0078] Wherein, the first pipe section 21 and the fourth pipe section 24 are both straight pipes. The length of the first pipe section 21 ranges from 65mm to 70mm; the bending angle of the first elbow section 221 is 90°; the length of the first straight pipe section 223 ranges from 20.2mm to 27.7mm; the bending angle of the second elbow section 222 is 100°; the length of the second straight pipe section 231 is 60mm-68mm; the bending angle of the third curved pipe section 232 is 133.8°; the length range of the third straight pipe section 233 is 80mm-92.2mm;...

no. 2 example

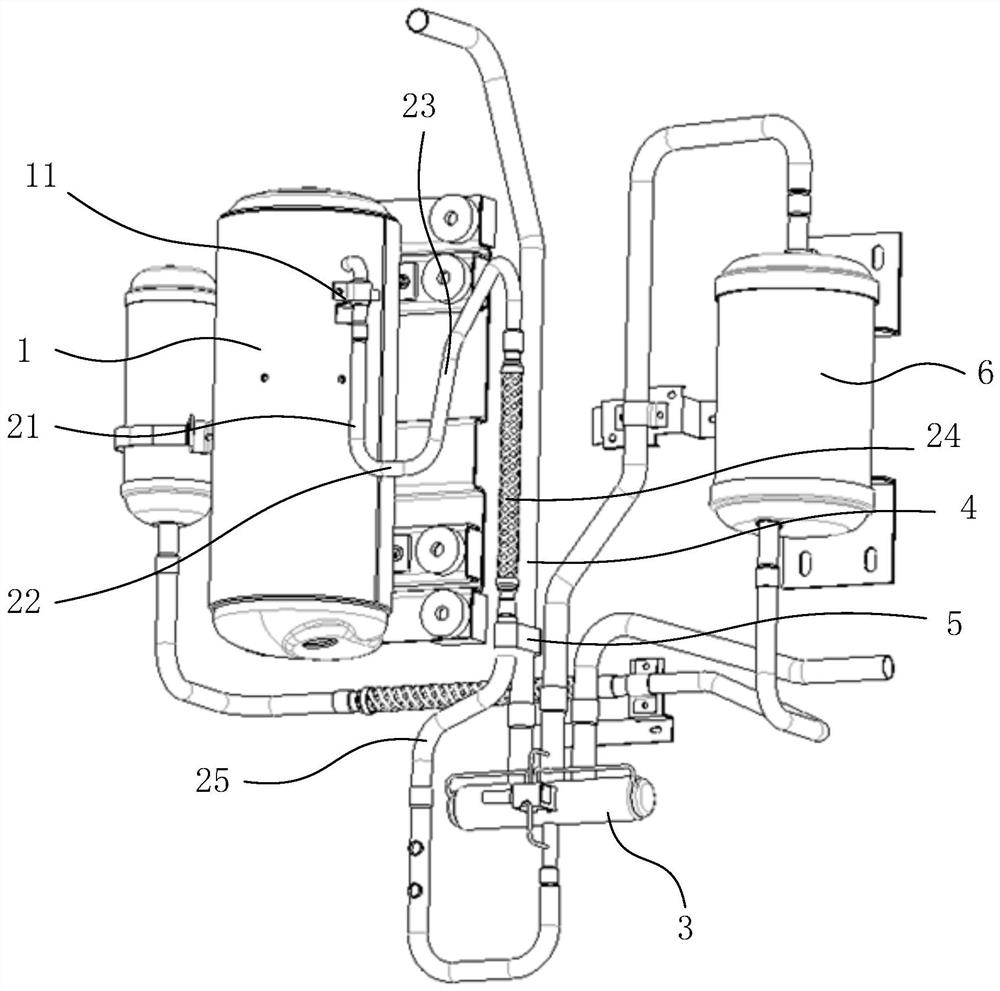

[0091] The difference between the second embodiment and the first embodiment is at least that: the fourth pipe segment 24 in the first embodiment is set as a hose, which has a better vibration damping effect compared to the first embodiment. Moreover, the length of the first pipe section 21 of the exhaust pipe 2 in the second embodiment is the same as that of the first pipe section 21 in the first embodiment, which reduces the rigidity of the exhaust pipe 2 .

no. 3 example

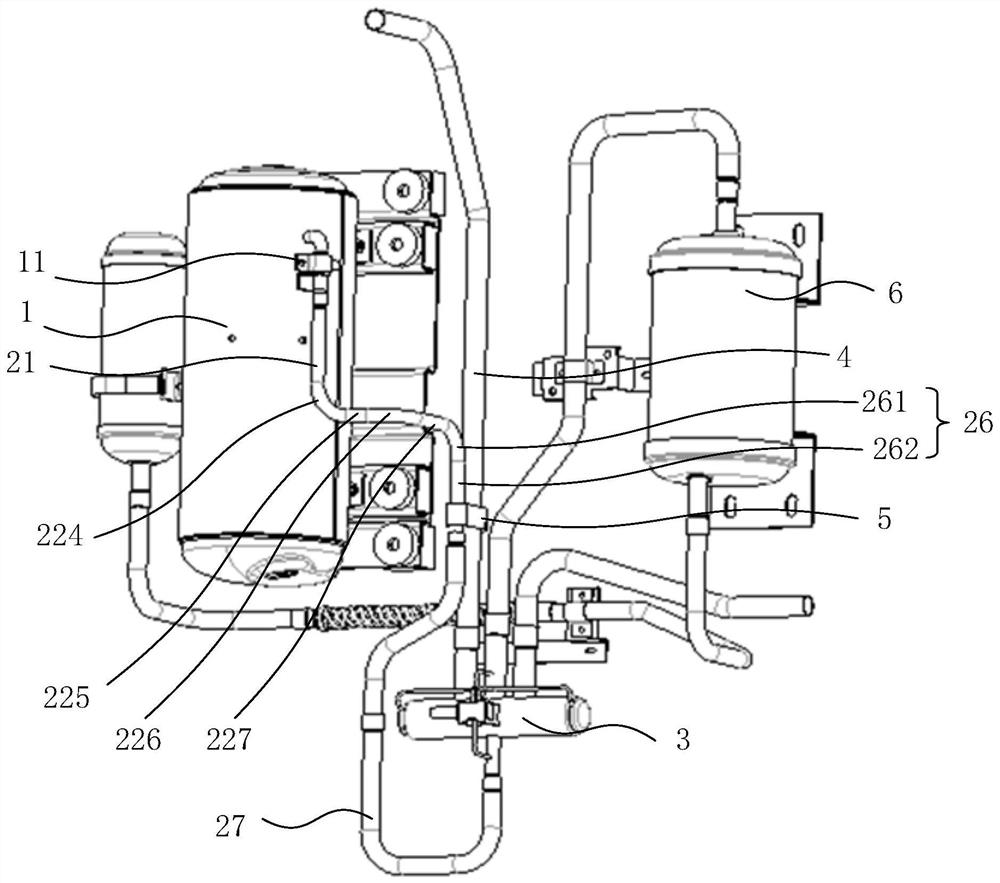

[0093] The exhaust pipe 2 includes a first pipe section 21 , a second pipe section 22 , a sixth pipe section 26 and a seventh pipe section 27 connected in sequence.

[0094] Wherein, the first pipe section 21 is a straight pipe.

[0095] The second pipe section 22 includes a fifth bent pipe section 224 , a fourth straight pipe section 225 , a sixth bent pipe section 226 and a fifth straight pipe section 227 connected in sequence. The fifth curved pipe section 224 is connected to the first pipe section 21 , and the fifth straight pipe section 227 is connected to the sixth pipe section 26 .

[0096] The sixth pipe section 26 includes a seventh bent pipe section 261 and a sixth straight pipe section 262 connected in sequence, the seventh bent pipe section 261 is connected to the second end of the second pipe section 22 , and the sixth straight pipe section 262 is connected to the seventh pipe section 27 .

[0097] Wherein, the length of the first pipe section 21 is 65mm-70mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com