Silver product and method of manufacturing silver product

一种制造方法、银制品的技术,应用在制造工具、磨削机床的部件、表面抛光的机床等方向,能够解决加工性差等问题,达到平滑度高、抑制金属过敏的产生、保持外观性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

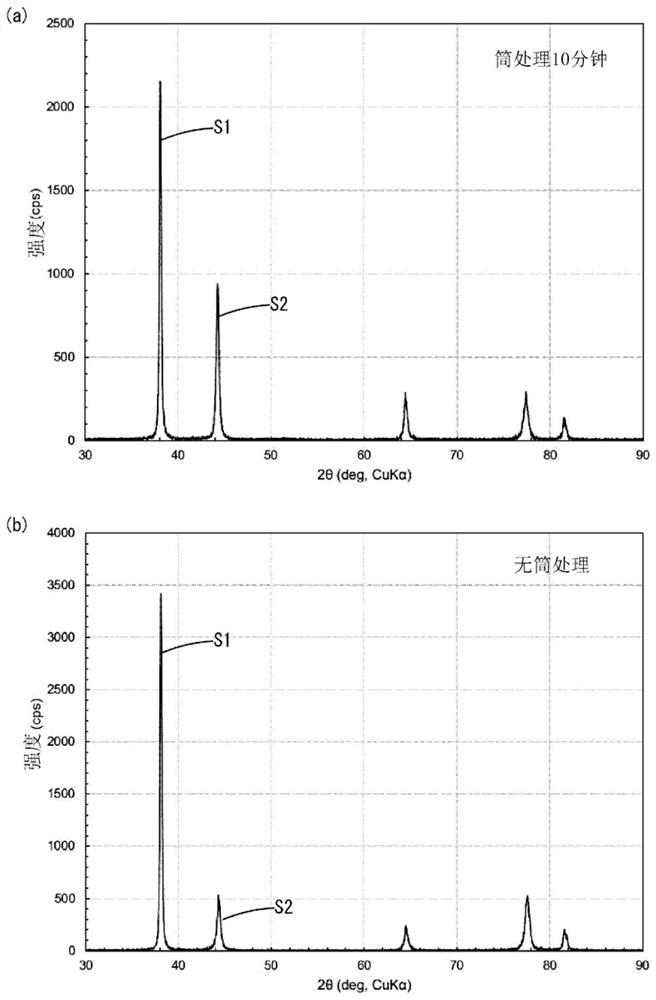

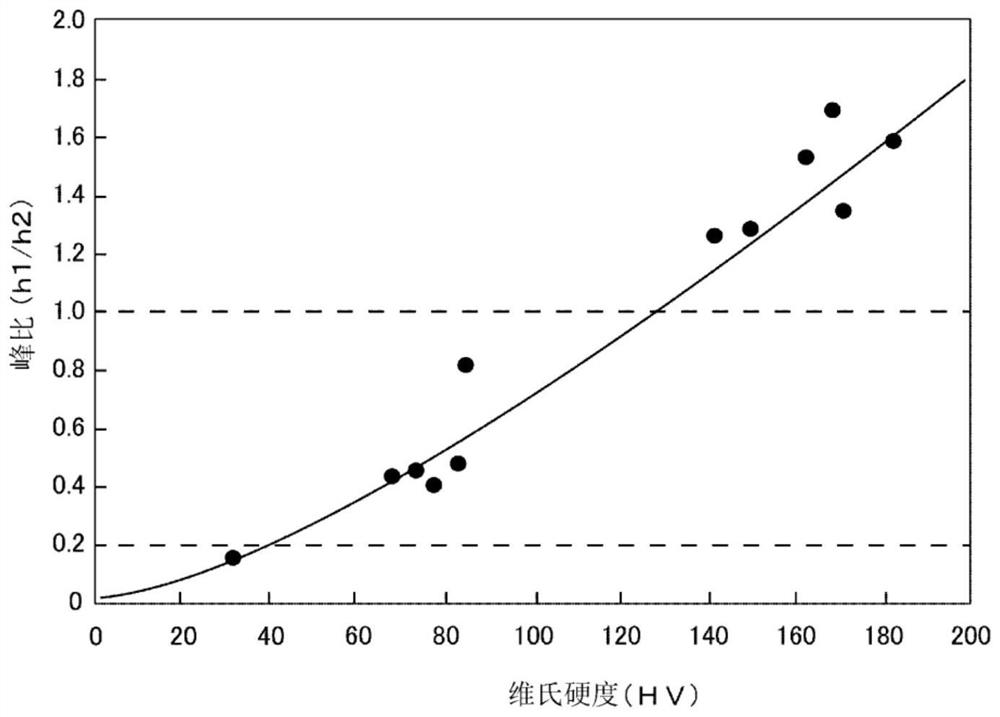

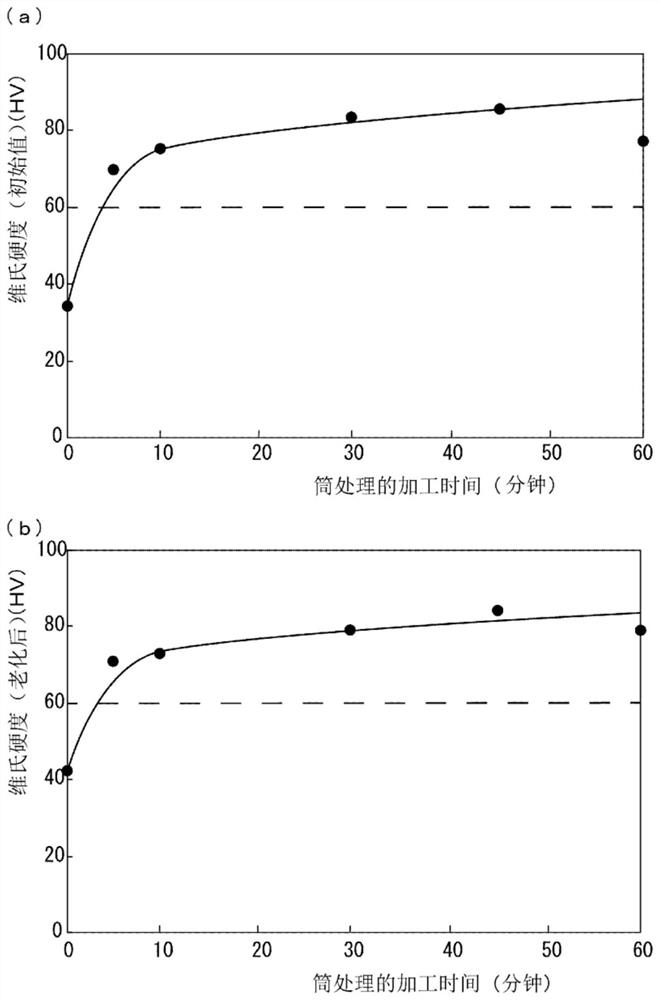

[0054] The first embodiment is a silver product, which is characterized in that it is a silver product formed of pure silver or a silver alloy having a purity of 99.9% by weight or more, the Vickers hardness of the silver product is 60HV or more, and as figure 1 As shown in (a) to (b), the height of the peak (S1) of 2θ=38°±0.2° in the X-ray diffraction pattern obtained by XRD analysis of the silver product is h1, and 2θ=44°± When the height of the peak (S2) at 0.4° is set to h2, such as figure 2 As shown, the value of h2 / h1 is 0.2 or more.

[0055] should be explained, figure 1 (a) is based on the X-ray diffraction pattern obtained by XRD analysis of Example 1, figure 1 (b) shows an X-ray diffraction pattern obtained by XRD analysis based on Comparative Example 1.

[0056] in addition, figure 2 It is a graph showing the relationship between the Vickers hardness (initial value) of a silver product and the ratio (h2 / h1) of the height (h1, h2) of a predetermined peak in an ...

no. 2 Embodiment approach

[0167] The 2nd embodiment is a kind of manufacturing method of silver product, it is characterized in that, the manufacturing method of the silver product that is formed by pure silver or the silver alloy that has 99.9% by weight or more purity, comprises following steps (1)~(2 ).

[0168] (1) The process of preparing a silver product of a prescribed shape

[0169] (2) Use a magnetic cylinder to carry out surface treatment on a silver product of a specified shape to make it work-hardened, so that the Vickers hardness of the silver product of the specified shape is 60HV or more, and the X-ray obtained by XRD analysis of the silver product of the specified shape In the ray diffraction diagram, when h1 is the peak height of 2θ=38°±0.2° and h2 is the peak height of 2θ=44°±0.4°, the value of h2 / h1 is 0.2 or more.

[0170] 1. Preparation process of silver products of specified shape

[0171] It is a process of preparing pure silver or a silver alloy having a purity of 99.9% by wei...

Embodiment 1

[0225] 1. Preparation process of silver products of specified shape

[0226] Silver having a purity of 100% by weight was prepared, and vacuum-deposited on a tempered glass substrate with a thickness of 0.5 mm using a metal vapor deposition apparatus to form a silver thin film with a thickness of 1 μm.

[0227] 2. Cartridge handling

[0228] use Figure 8 A magnetic cylinder apparatus, Pritic M (Puraioriti Co., Ltd.) shown in outline, performs cylinder processing on a silver thin film on a prepared strengthened glass substrate.

[0229] That is, 1000 g of water, 100 g of a silver product of a predetermined shape, 100 g of a magnetic material made of a spherical SUS (SUS304) with a diameter of 1 mm, and 1 g of a gloss agent were thrown into the stirring layer inside the tube device.

[0230] Next, the cartridge device was driven, and for the cartridge treatment, the cartridge treatment was performed for 10 minutes while rotating the stirred layer in the horizontal direction / v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com