Height-adjustable modular prestress fan foundation and construction method thereof

A wind turbine foundation and prestressing technology, which is applied in basic structure engineering, construction, etc., can solve problems such as large amount of foundation earthwork and cast-in-place concrete, water and soil conservation, large environmental impact, and non-recyclable and reused wind turbine foundation, etc., to achieve Quick and convenient lifting and installation, shortened construction period and high degree of mechanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

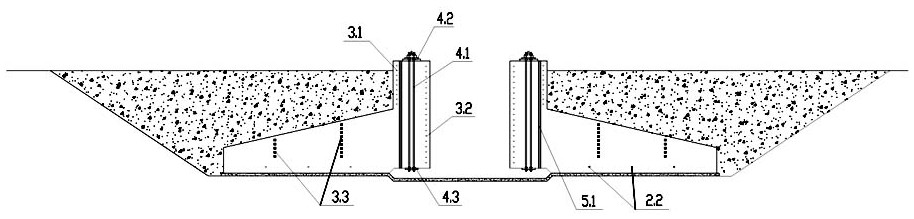

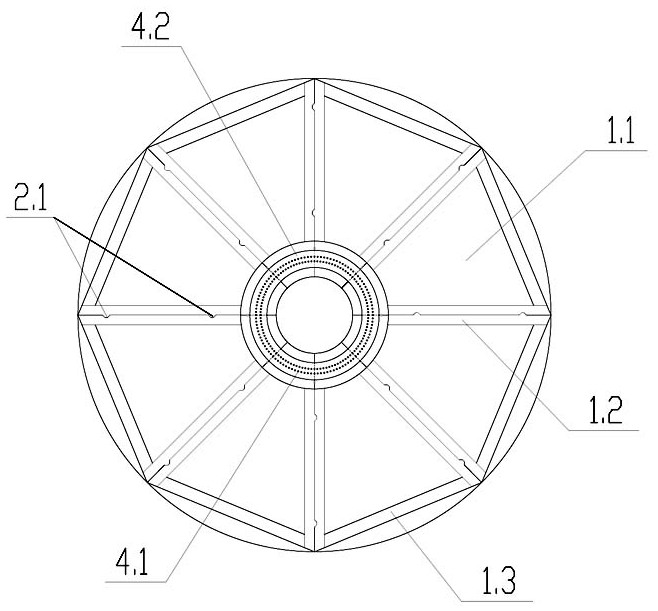

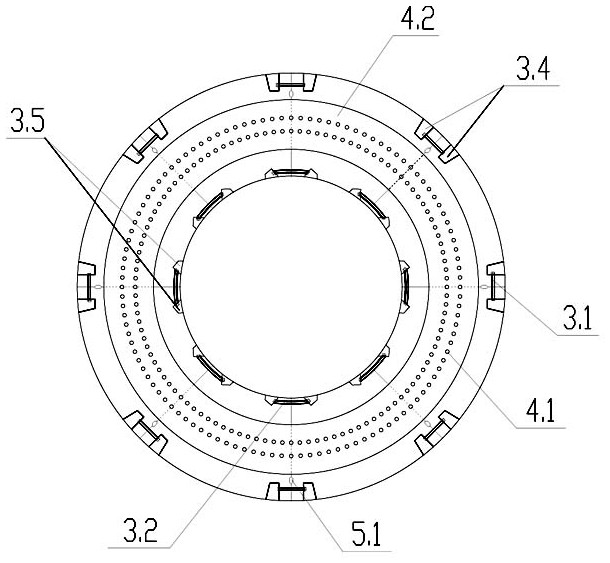

[0038] Such as Figure 1-3 As shown, the height-adjustable modular prestressed fan foundation of the present invention includes eight assembled units (the number can be adjusted according to the specific situation), the above-mentioned assembled units have the same structure, and they are spliced sequentially along the horizontal direction and connected through horizontal The fastening connection between the parts and the prestressed locking components constitutes a hollow closed ring structure. Each of the above-mentioned assembled units is composed of a central part and a flange part extending outside the central part. The central part is higher, and its top is used to install the fan (that is, the fan cap), and the flange part is to increase the central part. At the same time, it can also be assembled, positioned and fastened by setting up relevant mechanisms on the flange.

[0039] Specifically, the flange portion of each assembly unit includes a bottom plate 1.1 extend...

Embodiment 2

[0044] In order to deal with the flood control problem, simplify the construction and reduce the investment cost, the center part is prefabricated into two parts, that is, the fixed section 6.1 which is located at the lower part and the flange part is connected together and the height adjustment section 6.2 which is prefabricated separately at the upper part. Usually, the number of the height-adjusting section 6.2 and the fixed section 6.1 are the same. It is also possible to reduce the number of divisions of the height-adjusting section 6.2 while meeting the splicing requirements and keeping the splicing structure and the locking structure unchanged. Volume prefabrication to reduce the workload of prefabrication and hoisting. When assembling the height adjustment section 6.2 and the fixed section 6.1, the upper anchor plate 4.2 is located on the top surface of the height adjustment section 6.2, the lower anchor plate 4.3 is located on the bottom surface of the fixed section 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com