Negative current collector, negative pole piece and electrochemical device

A negative pole piece and current collector technology, applied in the field of electrochemical devices, can solve the problems of electrical performance degradation, affecting the performance of pole piece and battery, etc., and achieve the effect of low impedance, small polarization, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] The following examples describe the present disclosure more specifically, and these examples are for illustrative purposes only, since various modifications and changes within the scope of the present disclosure will be apparent to those skilled in the art. Unless otherwise stated, all parts, percentages, and ratios reported in the following examples are based on weight, and all reagents used in the examples are commercially available or synthesized according to conventional methods, and can be directly The instruments used without further processing, as well as in the examples, are commercially available.

[0134] Preparation

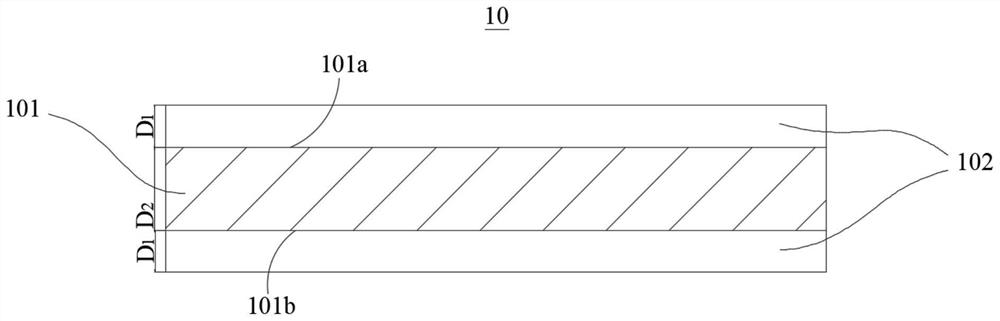

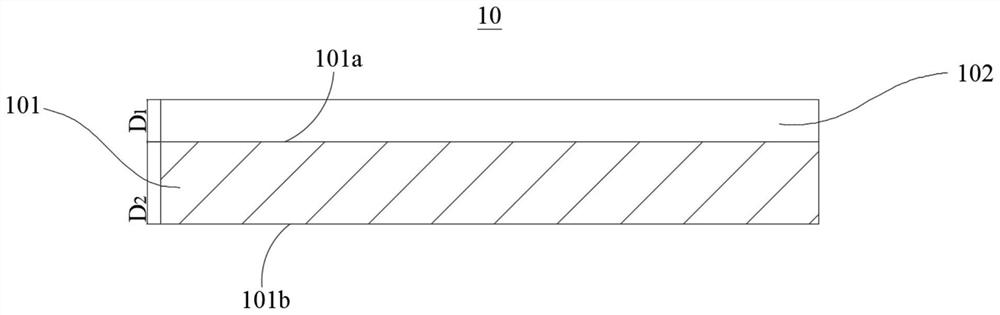

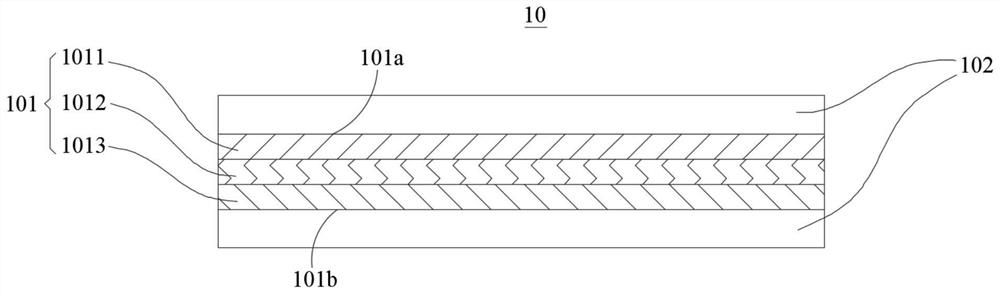

[0135] Preparation of negative electrode collector

[0136] Select a support layer with a predetermined thickness and perform surface cleaning treatment, place the support layer after surface cleaning treatment in a vacuum plating room, and melt and evaporate the high-purity copper wire in the metal evaporation room at a high temperature of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com