Superconducting lightning protection structure and assembly method thereof

A lightning protection and superconducting technology, which is applied in the usage of superconductor elements, installation of cables, installation of lighting conductors, etc., can solve problems such as fracture and affecting lightning protection functions, so as to improve the leakage effect, improve the firmness, and avoid The effect of bending fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

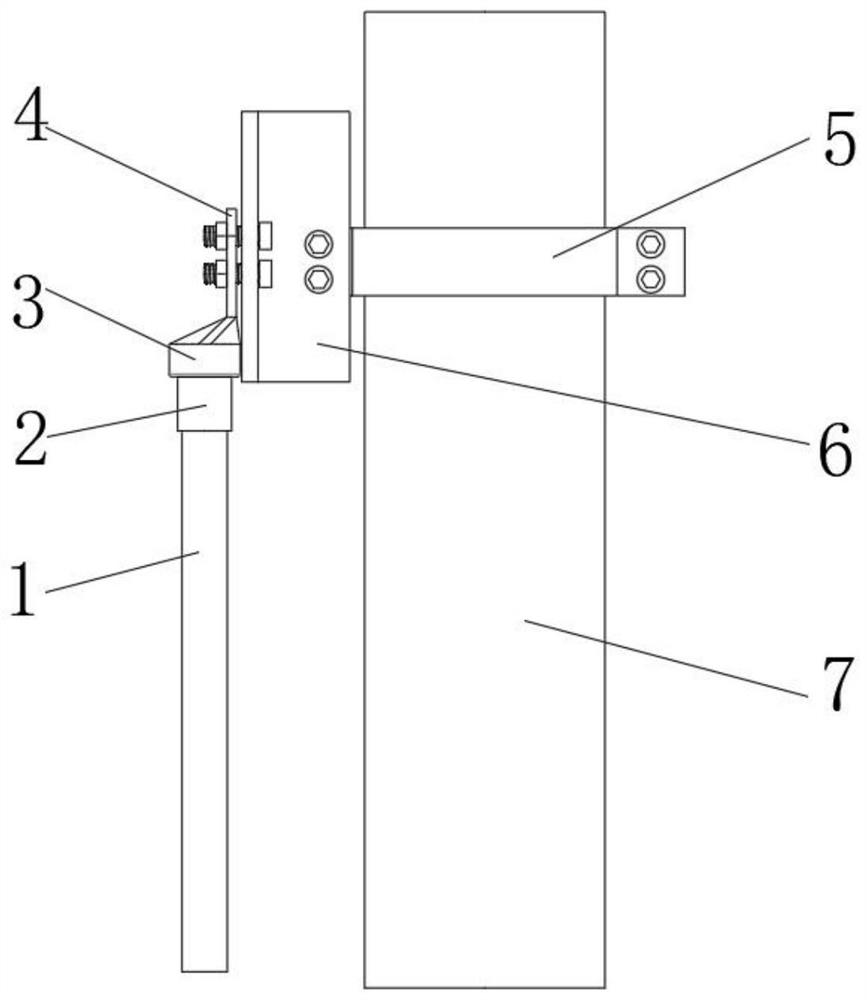

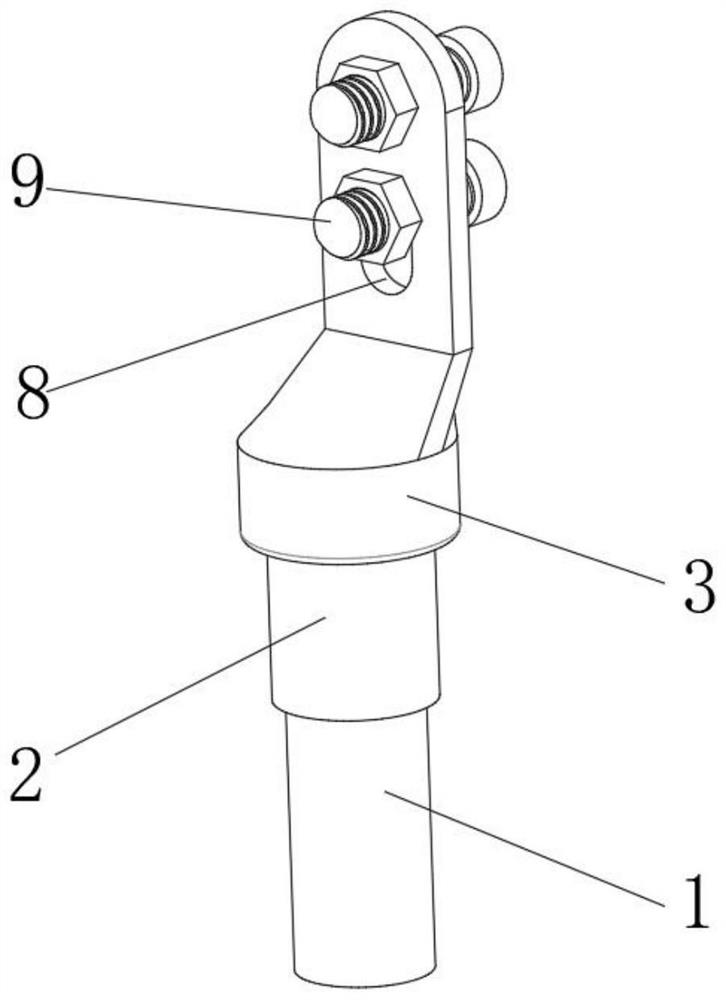

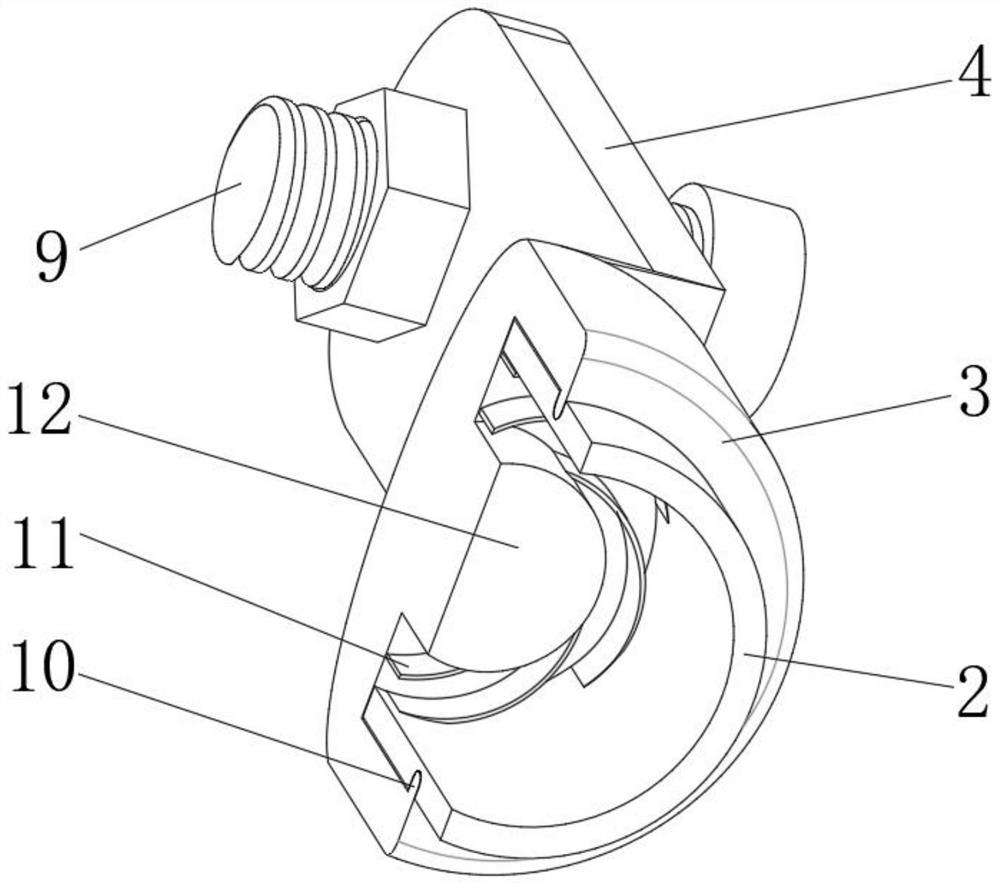

[0038] A superconducting lightning protection structure, such as Figure 1-5 As shown, it includes the down conductor 1 fixed on the pole tower 7 through the fixed angle steel 6 and the hoop 5; after the hoop 5 is socketed, it is fixed on the outer wall of the pole tower 7 by bolts, and the outer wall on one side of the fixed angle steel 6 is fixed on the outer wall of the pole tower 7 by bolts. The outer wall of one side of the hoop 5 and one end of the down conductor 1 are provided with a terminal shell 2, and the outer wall of the terminal shell 2 is slidably connected to a terminal seat 3 through an annular protrusion 10, and the top of the terminal seat 3 is integrally provided with a terminal head 4, and the terminal head 4 is a The side outer wall is tangent to the peripheral outer wall of the terminal base 3; the outer wall of the terminal head 4 is provided with an assembly hole and a waist hole 8, and the terminal head 4 is installed on the fixed angle steel 6 through...

Embodiment 2

[0047] An assembly method of a superconducting lightning protection structure, such as Figure 1-5 As shown, it includes the assembly of the down conductor 1 and the fixed angle steel 6 and the assembly of the down conductor 1 and the flexible graphite grounding body 13 or two flexible graphite grounding bodies 13; the assembly of the down conductor 1 and the fixed angle steel 6 includes the following steps :

[0048] S1: Insert one end of the down conductor 1 into the splicing fitting sleeve, the depth is not less than 170mm;

[0049] S2: Use a 600T ring reed press to squeeze the connecting fitting sleeve until it is fully compressed;

[0050] S3: Use M16 detachable anti-theft bolts to connect the down conductor 1 to the root of the tower through the terminal head 4 and the fixed angle steel 6.

[0051] The assembly of the downconductor 1 and the flexible graphite grounding body 13 or two flexible graphite grounding bodies 13 includes the following steps:

[0052] S11: pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com