Cleaning device and method for rotary target material

A technology of cleaning device and rotary drive device, which is applied to grinding drive device, grinding/polishing safety device, and parts of grinding machine tools, etc., can solve the problems of increasing the risk of target falling off, binding metal melting, and high cost, Achieve the effect of ensuring uniformity and coating quality and solving uneven sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

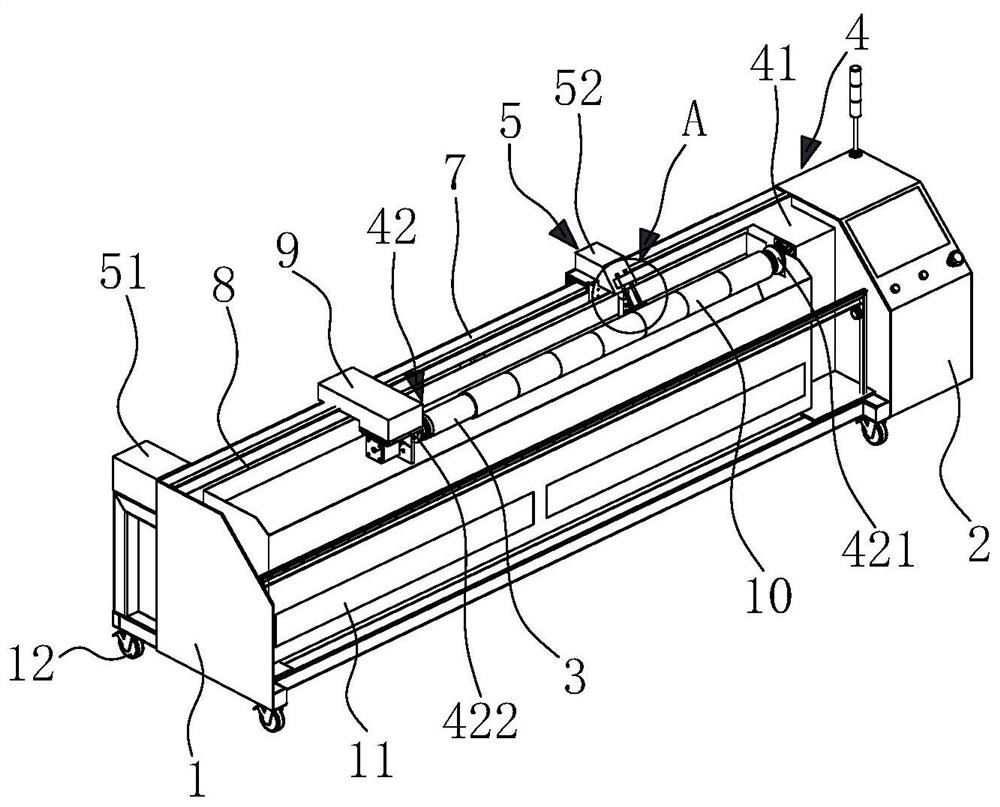

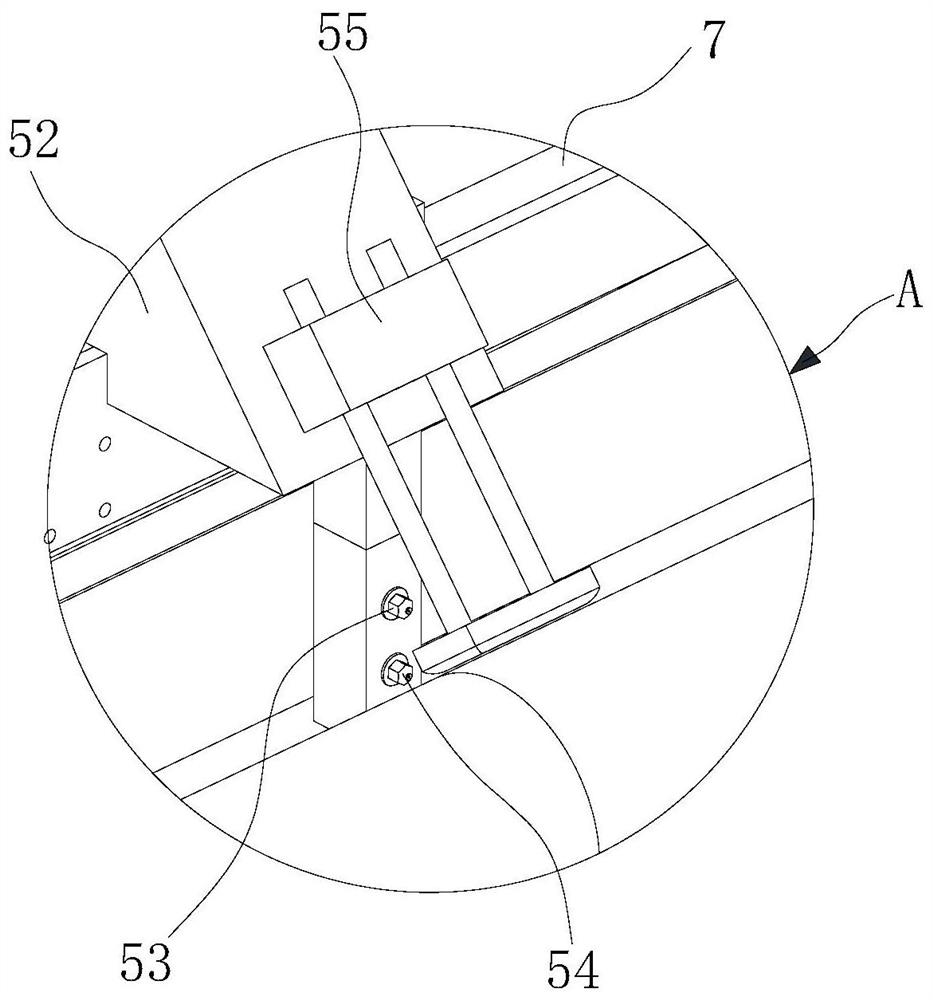

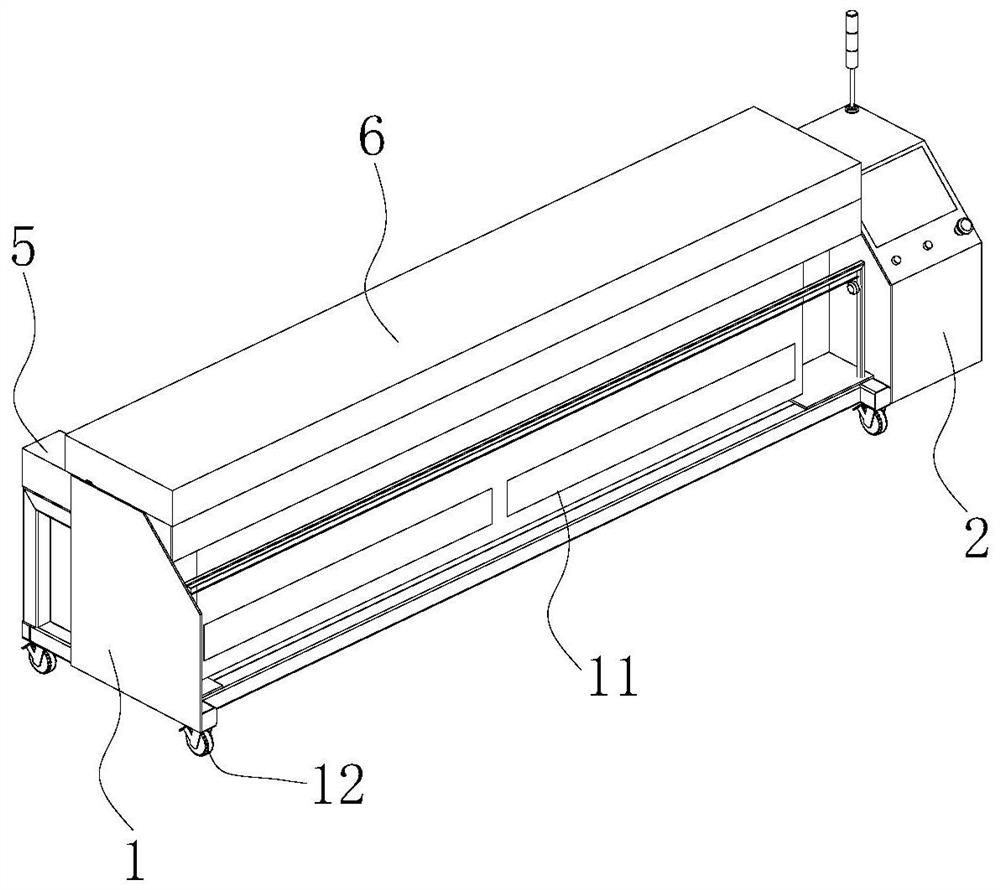

[0036] Such as Figure 1 to Figure 3 As shown, a cleaning device for a rotating target in a preferred embodiment of the present invention includes a frame 1, a mounting mechanism 4, a grinding and spraying mechanism 5, and a control device 2; the mounting mechanism 4 includes a rotary drive device 41 and a The positioning assembly 42 for the position of the liner 3, the rotation driving device 41 and the positioning assembly 42 are all installed on the frame 1, the rotation driving device 41 is connected with the positioning assembly 42, and the rotation driving device 41 can drive the positioning assembly 42 to rotate to drive the lining Pipe 3 rotates on frame 1; Grinding and spraying mechanism 5 comprises walking drive unit 51, first moving block 52, pressure device 55, spraying device 53, grinding piece (not shown in the figure) and polishing piece (not shown in the figure) shown), the walking drive device 51 is installed on the frame 1, the output end of the walking drive...

Embodiment 2

[0048] In order to solve the same technical problem, the present application also provides a cleaning method for a rotating target, which includes the following steps:

[0049] Step 1: Install the target material 10 on the liner 3, and install the liner 3 on the positioning assembly 42;

[0050] Step 2: the control device 2 controls the rotation driving device 41 to drive the positioning assembly 42 to rotate, so as to drive the liner 3 and the target material 10 to rotate on the frame 1, and at the same time, the liquid spray device 53 sprays detergent on the surface of the target material 10, The walking driving device 51 drives the first moving block 52 to drive the grinding piece to move, and the grinding piece is ground on the surface of the target 10;

[0051] Step 3: Stop grinding, the liquid spraying device 53 continues to spray detergent on the surface of the target 10, the traveling driving device 51 drives the first moving block 52 to drive the polishing piece to mo...

Embodiment 3

[0068] The difference between the present embodiment and the second embodiment is that the method for cleaning the rotating target provided by the third embodiment includes the following steps:

[0069] Step 1: select a liner 3 with a length of 3 meters, bind the 8-section copper indium gallium rotating target 10 on the liner 3, and assemble the liner 3 into the installation position, so that the two ends of the liner 3 touch the Connected to the surface of the first top cone 421 and the second top cone 422 .

[0070] Step 2: Assemble the grinding piece under the pressure device 55, the grinding piece is 360CW waterproof sandpaper, the control device 2 drives the pressure device 55 to press down, so that the grinding piece is close to the surface of the target 10, the pressure of the pressure device 55 is 0.2MPa . The control device 2 controls the rotation driving device 41 to drive the first cone 421 to rotate, and drives the target 10 and the liner 3 to rotate at a speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com