Oil pipe pushing and supporting manipulator device and usage method of minor repair platform

A manipulator and platform technology, which is applied in the field of oil pipe pushing and supporting manipulator devices for minor repair platforms, can solve the problems of inconvenient disassembly and assembly, small footprint, and large footprint, and achieves improved work efficiency, light weight, and low work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

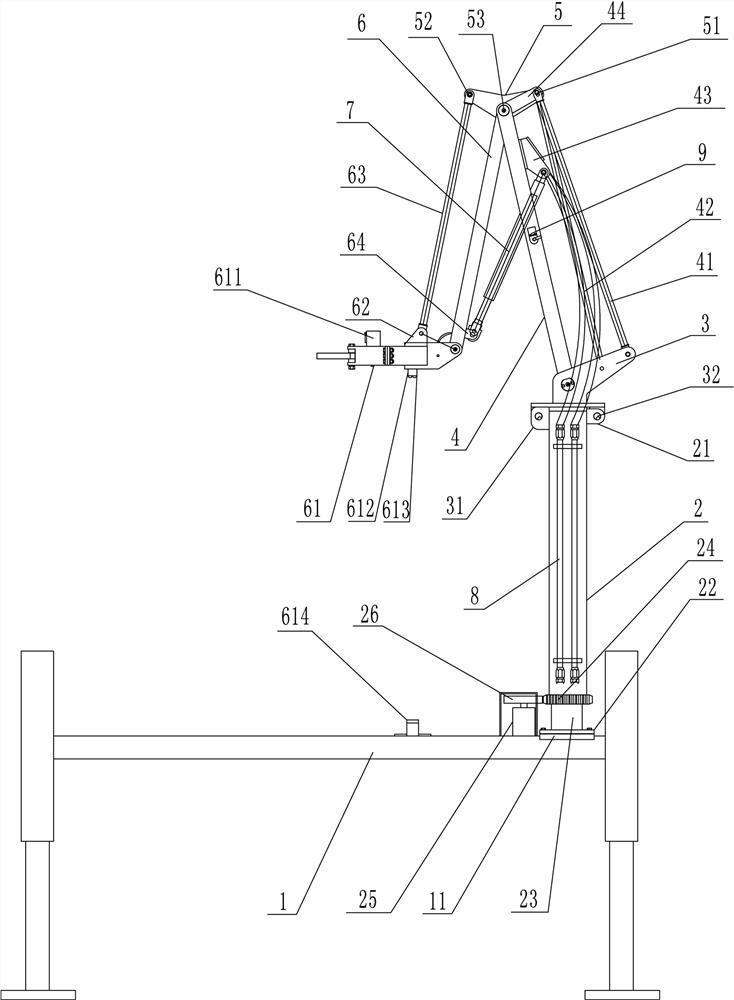

[0063] like image 3 As shown in the figure, the device is in the working state at this time, and the control box controls the oil cylinder 7 to extend through the control pipeline 8, so that the main mechanical arm 4 and the gripper 61 and the mechanical arm 6 generate an included angle; 61 The rear balance rod 42 and the balance arm 5 form a parallelogram link 44 structure; the gripper 61 and the gripper 61 mechanical arm 6, the gripper 61 front balance rod and the balance arm 5 also form a parallelogram link 44 structure; when When the oil cylinder 7 is extended, the main mechanical arm 4 will rotate around the hinge of the connecting seat 3, so the gripper 61 can extend in the horizontal direction; after reaching the designated position, the gripper 61 will grab the pipe string and grab the pipe string. Then control the oil cylinder 7 to retract to move the pipe string to the center of the wellhead, and then cooperate with the workover oil hoisting system to complete the mak...

Embodiment 2

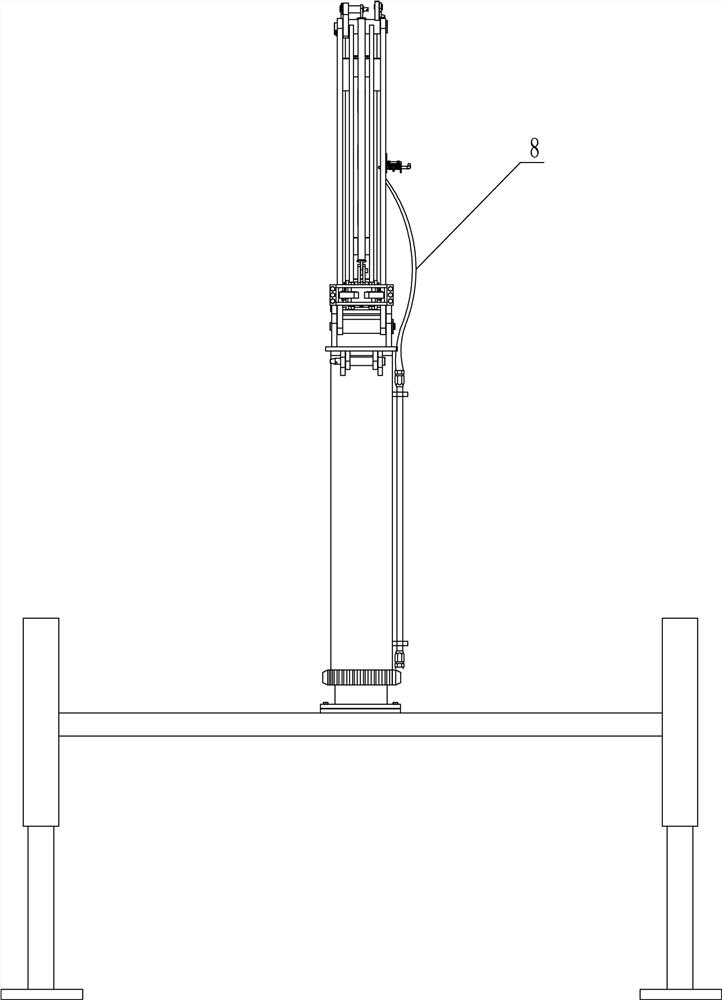

[0065] like Figure 4 As shown in the figure, the device body is in a standby state at this time, the oil cylinder 7 retracts, and the gripper 61 mechanical arm 6 is recovered to the position overlapping with the main mechanical arm 4; at this time, the main mechanical arm 4 and the gripper 61 mechanical arm 6 are in a vertical position state, retracted on the side of the work platform 1, leaving the space of the work platform 1 for the rest of the tools and personnel to work.

Embodiment 3

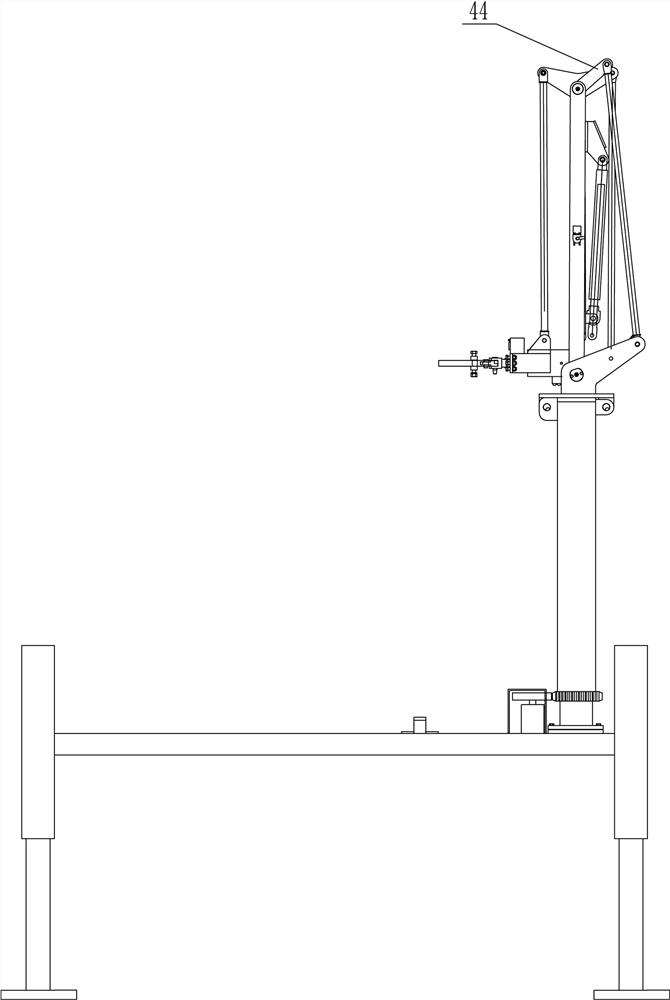

[0067] like Figure 5 As shown in the figure, the device is in a transport state at this time, and the manipulator on the upper part of the device is put down and folded; the oil cylinder 7 is retracted, so that the gripper 61, the manipulator 6 and the main manipulator 4 are upright and overlapped, and the locking pin 9 is inserted to connect the gripper 61 and the manipulator 6 with the main manipulator 4. The main mechanical arm 4 is connected and fixed to ensure that it will not spread out during folding and transportation; then the latch 32 is removed, and the connecting base 3 can rotate around the fixing pin 31 at this time, so that the entire mechanical arm above the connecting base 3 rotates around the support base 2. After the robot arm is lowered as a whole, a bracket is used to fix the lowered robot arm on the work platform 1, and the device body and the work platform 1 are transported together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com