Equipment and method for preparing rare earth oxide through conventional-microwave combined calcination

A rare earth oxide, conventional technology, applied in the field of conventional-microwave joint calcination to prepare rare earth oxides, to achieve the effects of reducing production costs, overcoming high energy consumption, and improving the technical level of rare earth oxide preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

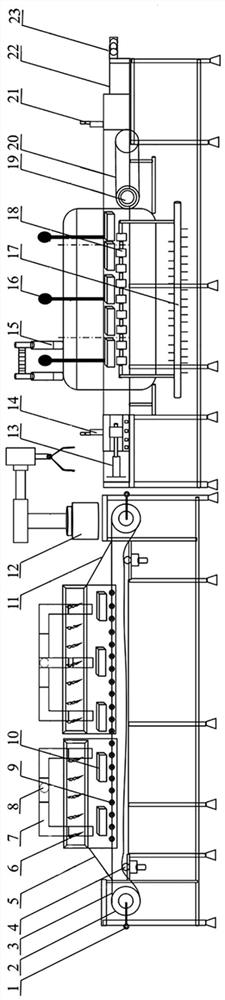

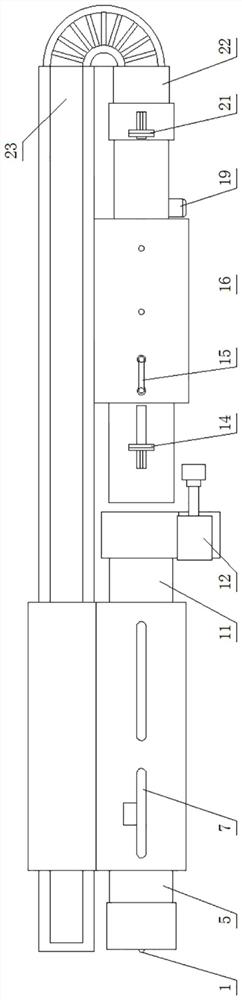

Method used

Image

Examples

Embodiment 1

[0041] S100: Weigh a certain amount of rare earth oxalate to be calcined and put it into a microwave-permeable sagger 10, and then send it into a conventional continuous heating furnace and slowly heat it to the preset 200°C and keep it warm. During the slow heating and heat preservation process Medium materials will gradually decompose into various low-moisture salts of oxalate, such as neodymium oxalate, which will undergo the following decomposition when heated:

[0042] Nd 2 (C 2 O4) 3 10H 2 O→Nd 2 (C 2 o 4 ) 3 ·8H 2 O→Nd 2 (C 2 o 4 ) 3 ·(8-n)H 2 O,

[0043] The low-moisture oxalate undergoes an endothermic reaction to fully decompose the free and unstable moisture, and then dehumidifies it through the opened dehumidification device 7, and heats it for a preset time before it is released from the oven.

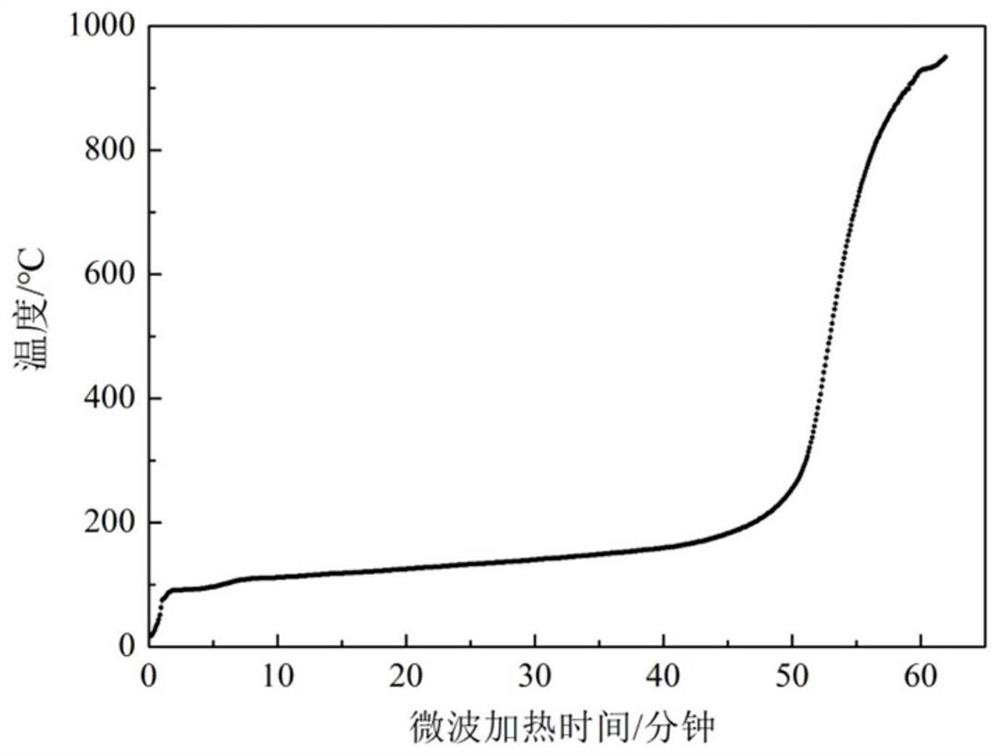

[0044] S200: Send the sagger 10 out of the conventional continuous heating furnace into the walking microwave heating furnace, and the sagger 10 is transport...

Embodiment 2

[0049] S100: Weigh a certain amount of rare earth oxalate to be calcined, put it into a microwave-permeable sagger 10, and send it into a conventional continuous heating furnace and slowly heat it to the preset 170°C and keep it warm. During the slow heating and heat preservation process The medium material will gradually decompose into various low-moisture salts of oxalate, and the low-moisture oxalate undergoes an endothermic reaction to fully decompose the free and unstable water, and then dehumidify through the opened dehumidifier 7, and keep warm until the preset time. It will be released after the set time.

[0050] S200: Send the sagger 10 out of the conventional continuous heating furnace into the walking microwave heating furnace, and the sagger 10 is transported by the stepping conveying device to the superposition of the wave peak and the wave peak of the adjacent magnetron 18, according to It is necessary to set the heating rate and holding time. The low-moisture r...

Embodiment 3

[0053] S100: Weigh a certain amount of rare earth carbonate to be calcined, put it into the microwave-permeable sagger 10, send it into a conventional continuous heating furnace and slowly heat it to the preset 230°C and keep it warm. During the slow heating and heat preservation process The medium material will be gradually decomposed into various low-moisture salts of carbonates, and the low-moisture carbonates will undergo endothermic reactions to fully decompose the free and unstable moisture, and then dehumidify through the opened dehumidifying device 7 and keep warm until the preset time. It will be released after the set time.

[0054] S200: Send the sagger 10 out of the conventional continuous heating furnace into the walking microwave heating furnace, and the sagger 10 is transported by the stepping conveying device to the superposition of the wave peak and the wave peak of the adjacent magnetron 18, according to It is necessary to set the heating rate and holding tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com