Small molecular group water production equipment

A technology of small molecular mass water and equipment, applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., to achieve the effect of ensuring the quality of finished water, strengthening adaptability and immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

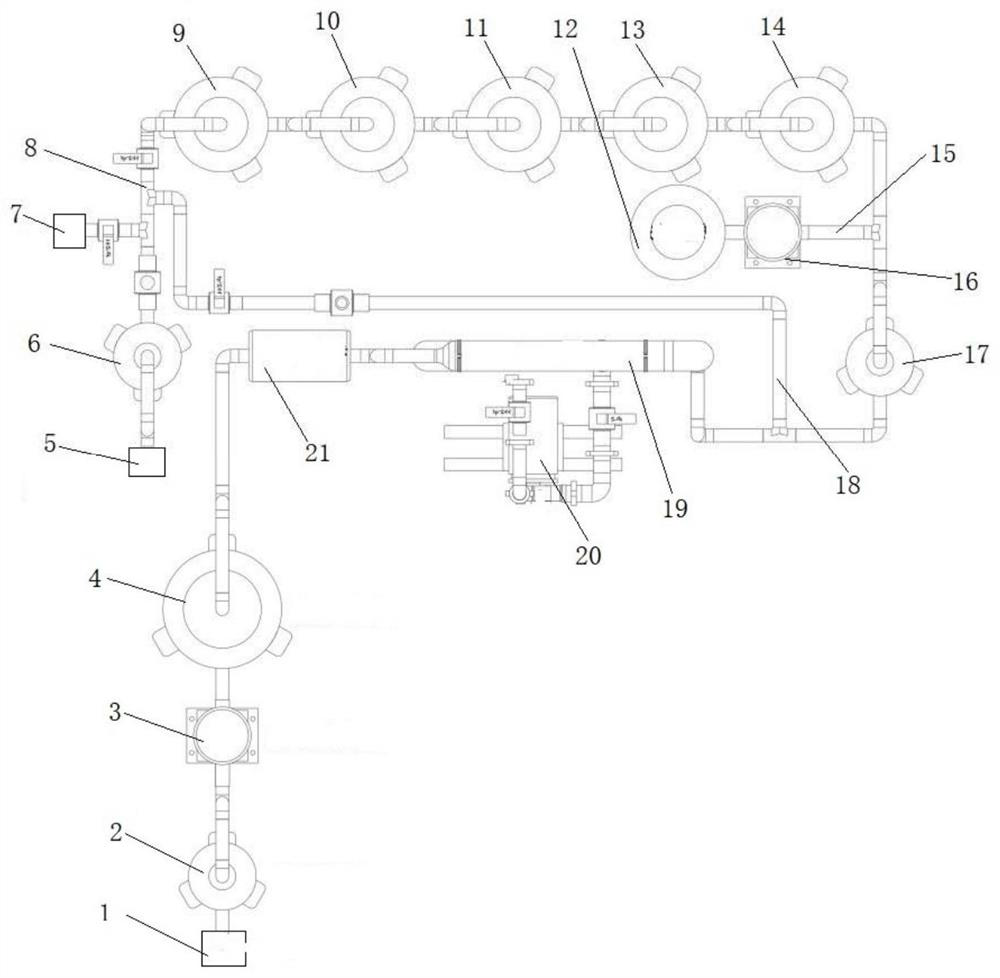

[0019] Such as figure 1 As shown, a small molecular mass water production equipment includes a raw water tank, a pure water tank and a finished product water tank. The water inside the pure water tank is secondary RO pure water and nanofiltration water. The water outlet of the pure water tank is connected to the first The branch pipe connection is equipped with an electronically controlled flow valve for controlling the incoming flow of pure water. The TDS value of the mixed secondary RO pure water, nanofiltration water and raw water is 40-80. The outlet of the raw water tank is connected to the first filter. The water outlet of a filter and the pure water tank are connected through the first branch pipe, and the water outlet of the pure water tank is provided with a first filter tank, a second filter tank, a third filter tank, a fourth filter tank, and a fifth filter tank in sequence according to the direction of water flow. The filter tank, the water outlet end of the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com