Water treatment device and method for circulating aquaculture system

A technology for recirculating aquaculture and water treatment devices, which is applied in the fields of water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. It can achieve the effect of large water treatment capacity, low energy loss and small treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

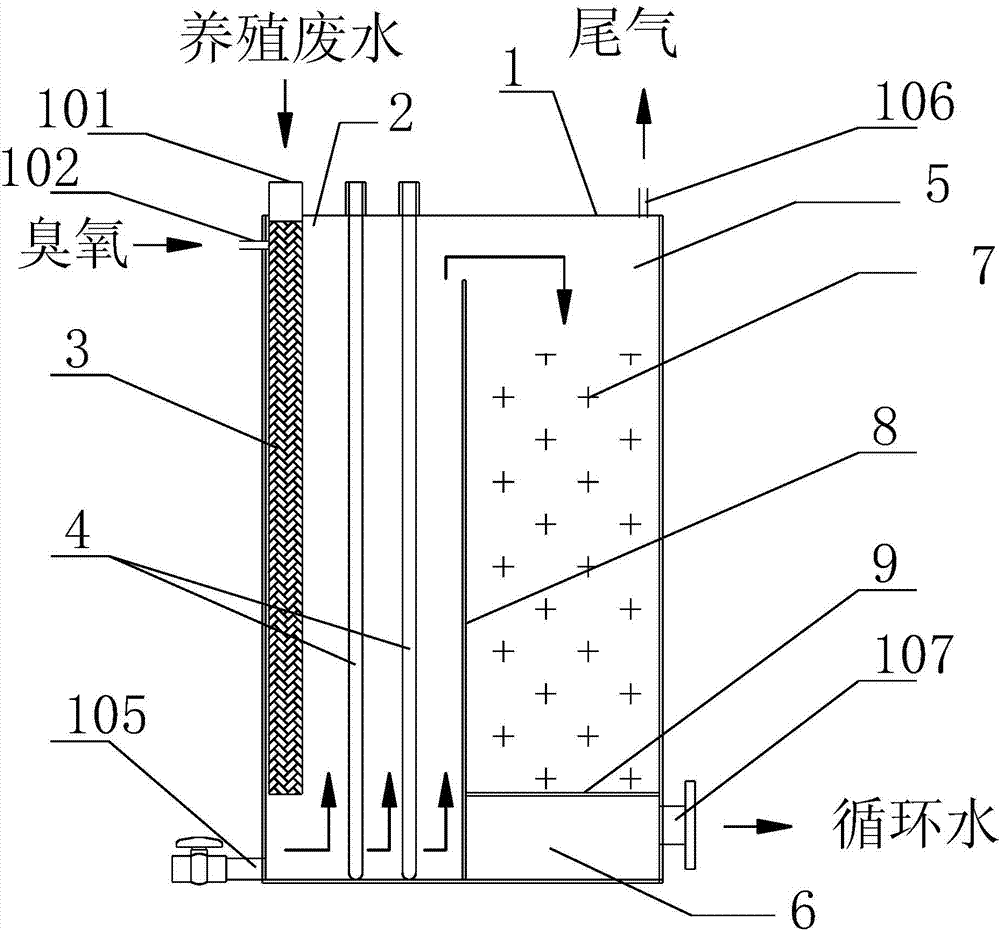

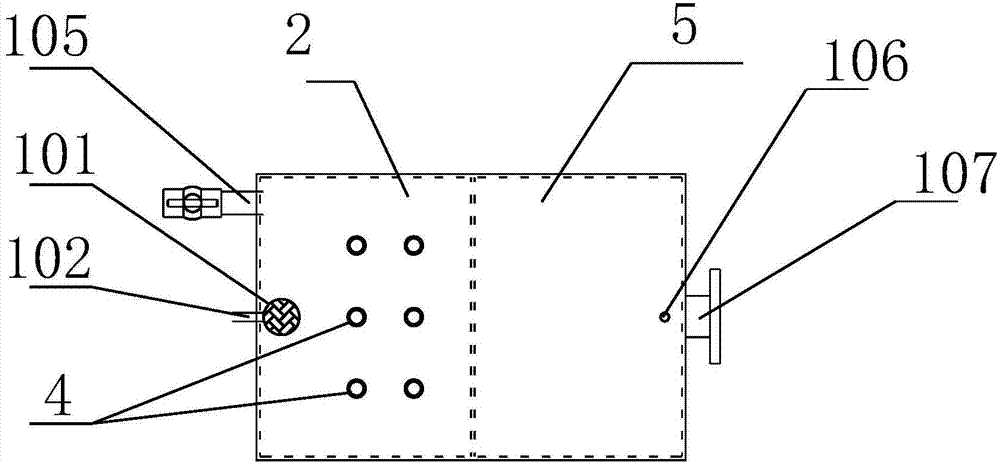

[0037] Such as figure 1 and figure 2 As shown, a water treatment device for a circulating aquaculture system is structured as a closed box, and the interior of the box is divided into two chambers, the ultraviolet radiation area and the biological filler reaction area, by a vertical partition, and the lower end of the partition is Fixed on the bottom plate, the distance between the top of the partition and the top of the box is 5-10cm. The ultraviolet radiation area and the biological filler reaction area are only communicated through the gap between the top of the partition and the top of the box.

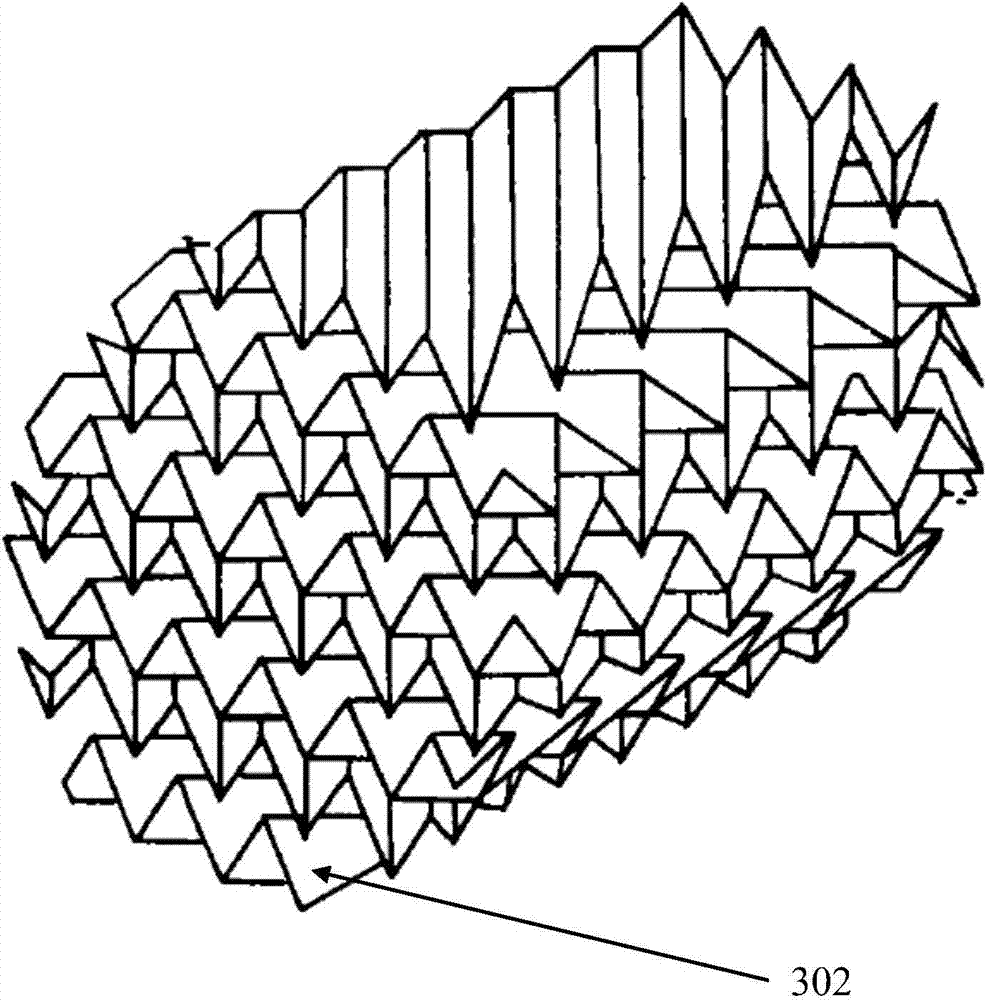

[0038] The tubular static mixer 3 is arranged on the side away from the partition in the ultraviolet radiation area, the top is the water inlet 101 and the ozone air inlet 102, fixed on the top of the box, and the bottom is the outlet, leaving a distance from the bottom of the box. The distance between the outlet of the static mixer and the bottom of the box is 10% to 20% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com