Multi-layer cold and hot sharing vacuum freeze-drying system

A vacuum freeze-drying, multi-layer technology, applied in the direction of drying solid materials without heating, drying, drying machine, etc., can solve the problems of waste of condensation end, high investment and high cost of refrigeration units, and improve the production and processing speed. , High system efficiency, obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

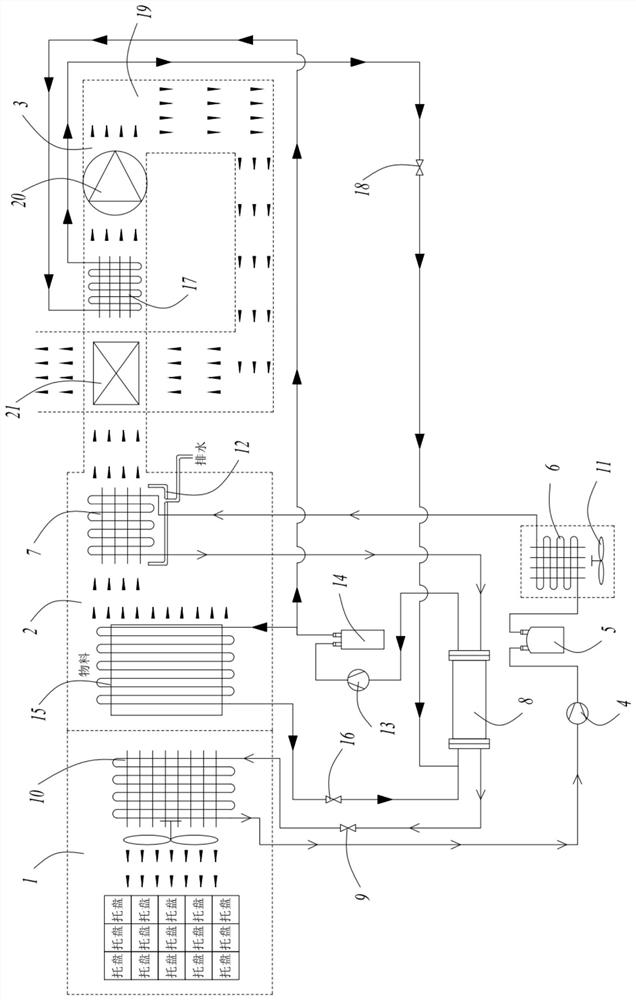

[0022] Such as figure 1 A vacuum freeze-drying system with multi-level cooling and heating is shown, including a pre-freezing unit 1, a dehydration unit 2, a negative pressure unit 3, and a heat pump unit for providing heat and cold energy. After the product is frozen in the pre-freezing unit 1, Enter the dehydration unit 2 and perform dehydration operation in the dehydration unit 2. The dehydration unit 2 ensures that the interior of the dehydration unit 2 is a negative pressure through the negative pressure unit 3, so that the water vapor inside the dehydration unit 2 is discharged to ensure that the interior of the dehydration unit 2 is dry. The heat pump unit described above includes a high-temperature side heat pump assembly and a low-temperature side heat pump assembly. The above two heat pump assemblies form a cascade heat pump system....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com