Moisture regaining control system with moisture control function

A technology of control function and control system, applied in control/regulation system, humidity control, non-electric variable control, etc., can solve problems such as large fluctuation of material flow, affecting the accuracy of material moisture regain, and difficulty in effectively controlling material moisture, etc. The effect of reducing some processes, improving processing efficiency and space utilization, and shortening material processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

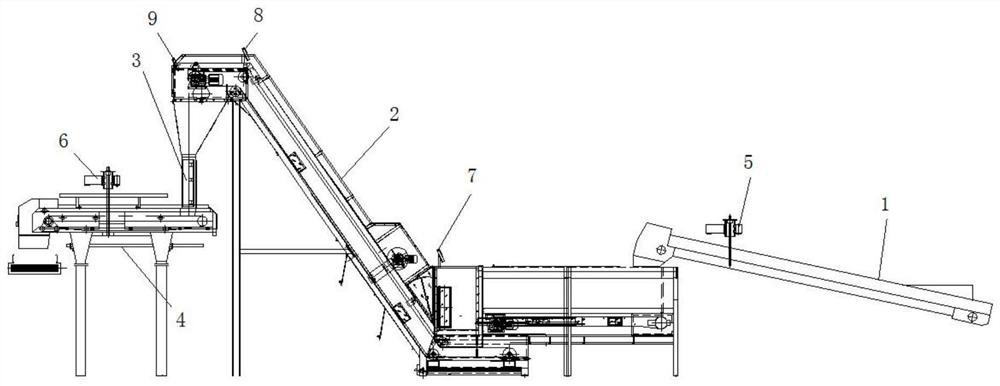

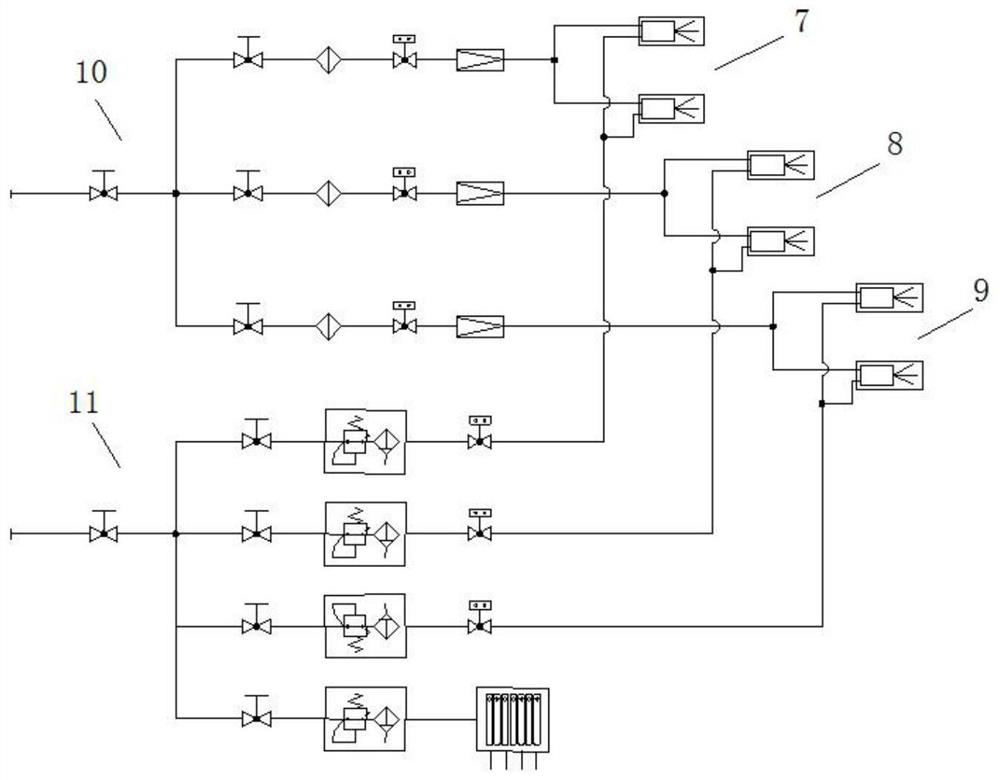

[0015] like figure 1 , 2 As shown, a moisture regain control system with a moisture control function includes a feed belt 1, a feeder 2, a metering tube 3 and an electronic scale 4, the end of the feed belt 1 is provided with a first moisture meter 5, The upper end of the electronic balance 4 is provided with a first moisture meter 5, and the feed end and the discharge end of the feeder 2 are respectively provided with a first atomizing nozzle 7 and a second atomizing nozzle 8 for spraying water on the material. , the top of the metering tube 3 is provided with a third atomizing nozzle 9, the spraying direction of the third atomizing nozzle 9 is directly facing the thrown material, and the first moisture meter 5 detects the water content in the material to control the second The amount of water added to the first atomizing nozzle 7, the second mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com