A prefabricated ultra-high performance concrete steel bridge deck pavement structure and its preparation method

An ultra-high performance, concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve problems such as difficult flatness control, rivet welding damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

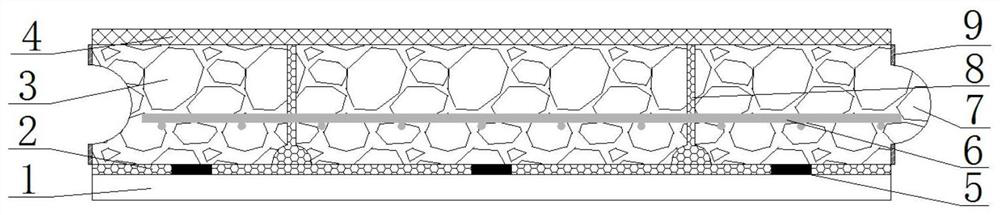

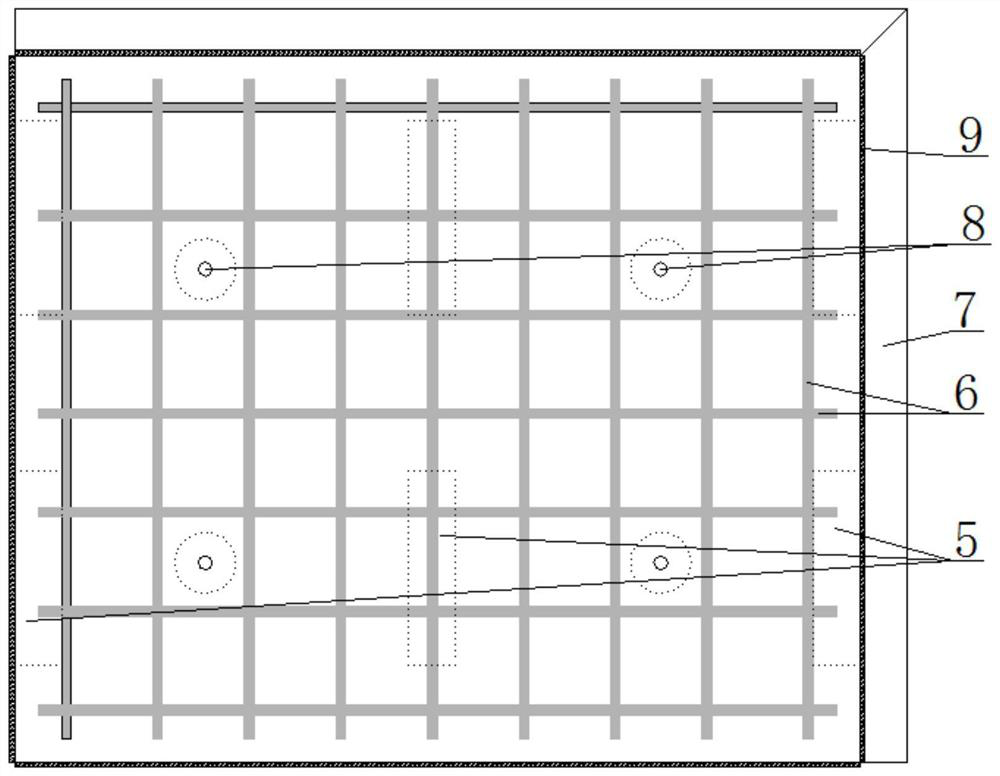

[0059] The prefabricated ultra-high performance concrete steel bridge deck pavement structure and preparation method in the embodiment of the present invention include the following steps:

[0060] S1. Use threaded ribbed steel bars with a diameter of 8-10mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 50-100mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars. ~20mm;

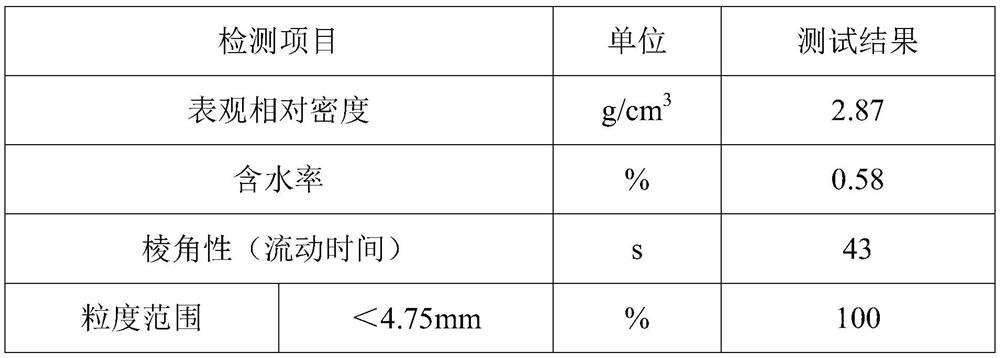

[0061] S2. Weigh 25-30 parts of Portland cement, 6-10 parts of silica fume, 8-12 parts of quartz powder, 30-35 parts of quartz sand with particle size ≤ 1mm, 2-4 parts of composite chopped steel fiber and 4-8 parts of basalt fiber, 8-12 parts of water, 1-2 parts of polycarboxylate high-efficiency water reducer, use a horizontal mixer to stir the dry mixture at a rate of 25-35 rpm for 1 min, and then add basalt fiber and steel fiber, then add water...

Embodiment 1

[0072] A prefabricated ultra-high performance concrete steel bridge deck pavement structure and a preparation method thereof, comprising the following steps:

[0073] S1. Use threaded ribbed steel bars with a diameter of 8mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 50mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars to 20mm;

[0074] S2. Weigh 25 parts of Portland cement, 8 parts of silica fume, 12 parts of quartz powder, 35 parts of quartz sand with particle size ≤ 1mm, 4 parts of composite chopped steel fiber, 6 parts of basalt fiber, 8 parts of water, Carboxylic acid high-efficiency water reducer 2 parts, use a horizontal mixer to stir the dry mixture at a rate of 35 rpm for 1 minute, add basalt fiber and steel fiber in turn, then add water reducer and mixing water, and wet mix for 8 minutes to prepare ne...

Embodiment 2

[0090] A prefabricated ultra-high performance concrete steel bridge deck pavement structure and a preparation method thereof, comprising the following steps:

[0091] S1. Use threaded ribbed steel bars with a diameter of 10mm to make steel mesh sheets, set the horizontal and vertical steel bar spacing to 75mm, place them in a fixed mold to form high-density fiber concrete prefabricated panels, and control the thickness of the steel mesh protective layer by welding trapezoidal steel bars to 15mm;

[0092] S2. Weigh 27 parts of Portland cement, 10 parts of silica fume, 10 parts of quartz powder, 33 parts of quartz sand with particle size ≤ 1mm, 3 parts of composite chopped steel fiber, 5 parts of basalt fiber, 10 parts of water, and Carboxylic acid high-efficiency water reducer 2 parts, use a horizontal mixer to stir the dry mixture at a rate of 35 rpm for 1 minute, add basalt fiber and steel fiber in turn, then add water reducer and mixing water, and wet mix for 6 minutes to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com