OCA specific silicone oil release film

A technology of release film and silicone oil, which is applied in the direction of film/sheet release liner, film/sheet adhesive, layered products, etc. It can solve the problems affecting the use and the adhesion of the adhesive layer, etc., to achieve convenience The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

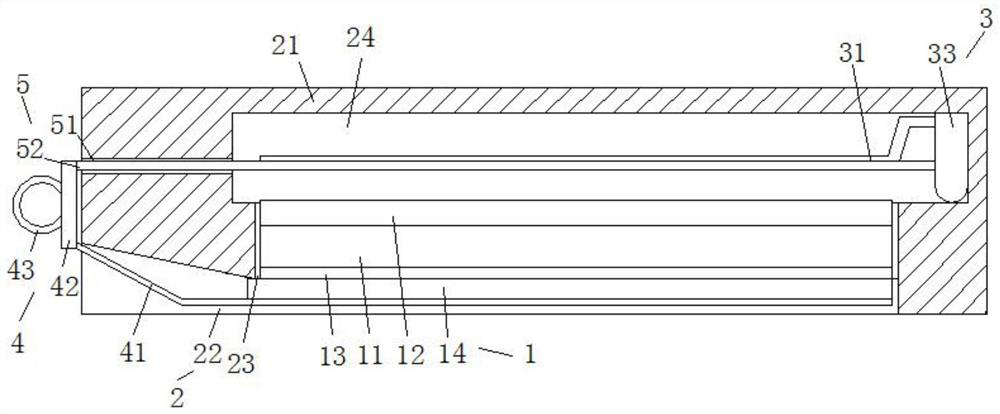

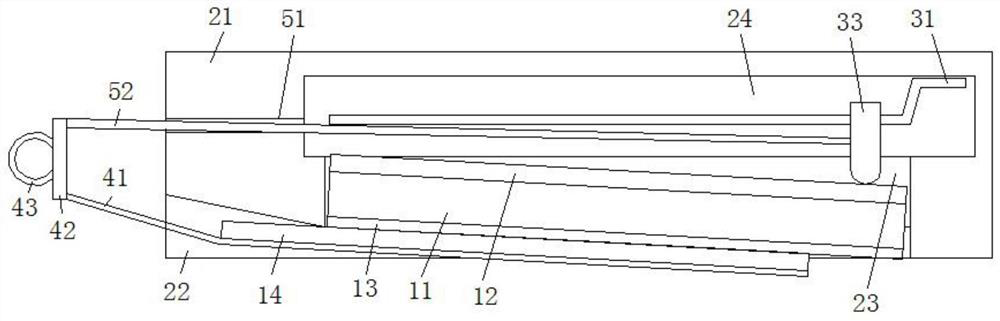

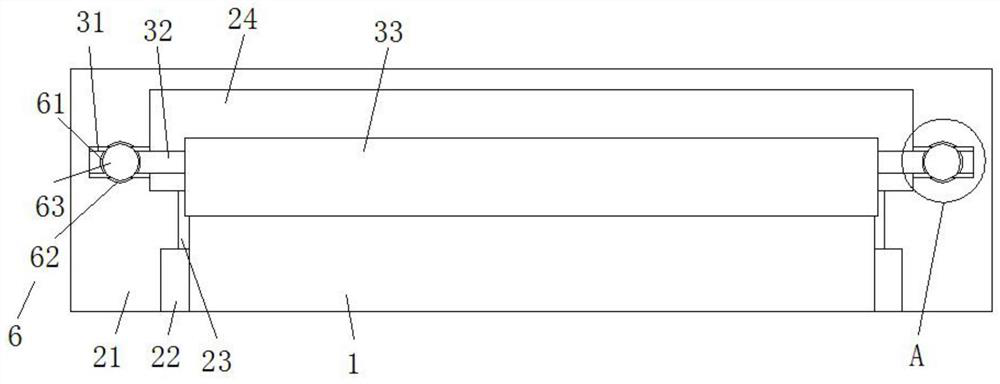

[0025] Example: such as Figure 1-5 As shown, an OCA-specific silicone oil release film of the present invention includes a release film 1, and a placement mechanism 2 is set on the outside of the release film 1, and the interior of the placement mechanism 2 is set at the position of the release film 1 There is a pressing mechanism 3, the bottom of the release film 1 is provided with a film tearing mechanism 4, a connecting mechanism 5 is arranged between the film tearing mechanism 4 and the pressing mechanism 3, and a connecting mechanism 5 is arranged inside the pressing mechanism 3. rolling mechanism6.

[0026] Wherein, the release film 1 includes a PET material layer 11, the upper surface of the PET material layer 11 is fixedly connected with a layer of transparent protective layer 12, and the lower surface of the PET material layer 11 is fixedly connected with a layer of OCA adhesion layer 13, and the OCA adhesion layer 13 The lower surface is fixedly connected with a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com