Sole smoothing device used before adhesion of soles and vamps

A technology for smoothing and vamps, which is applied to footwear, shoemaking machinery, clothing, etc., and can solve problems affecting adhesion, unevenness, and the tightness between shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

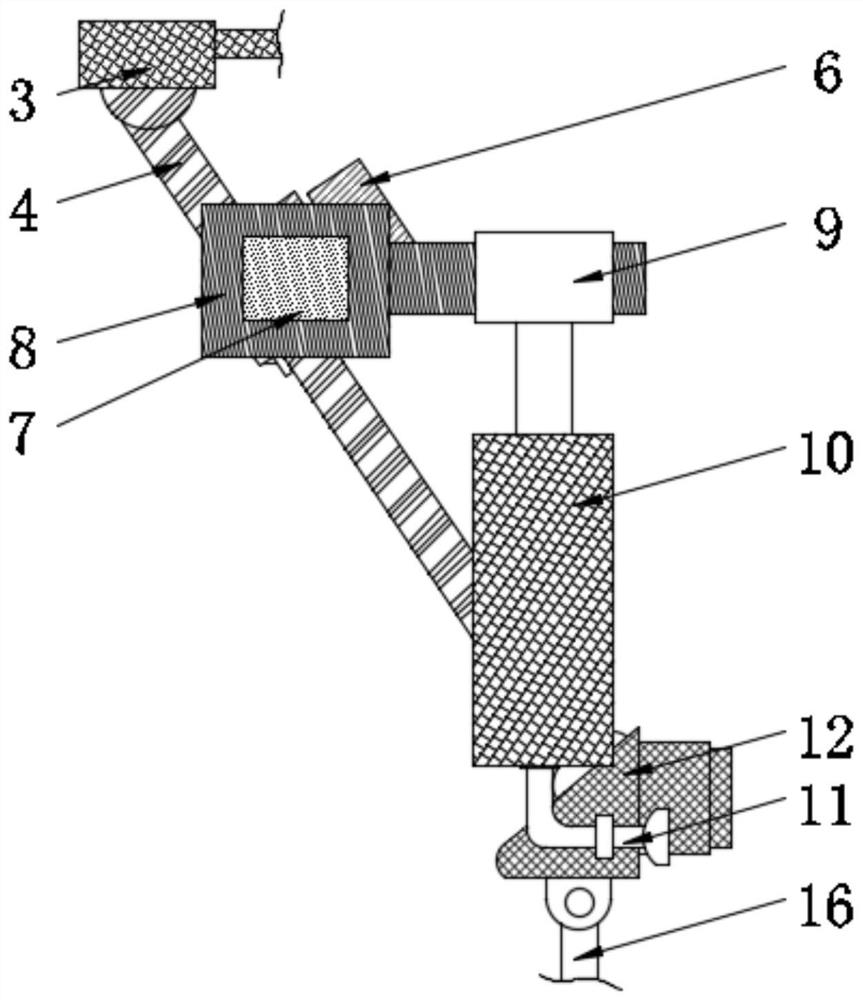

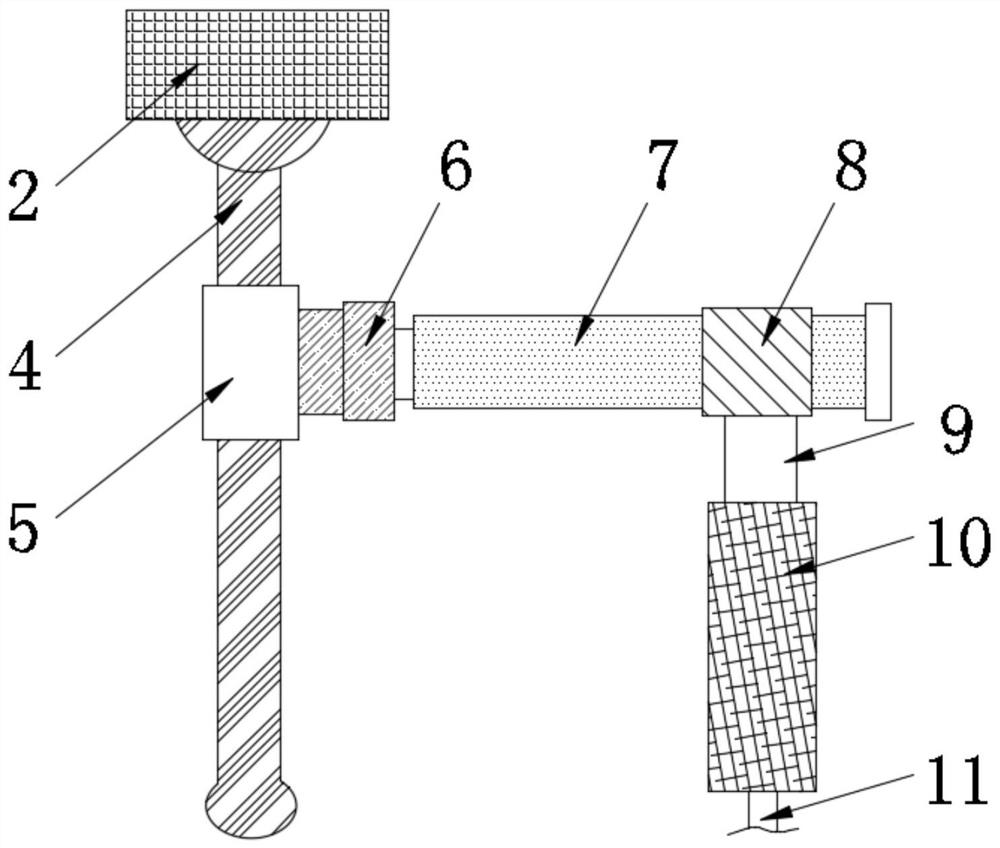

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] The invention provides a shoe sole grinding device before the shoe sole and upper are adhered, as attached figure 1 To attach Figure 5 Shown: including the processing chamber 1, the inner rotation of the processing chamber 1 is installed with the turntable 2, the top of the turntable 2 is fixedly connected to the output end of the motor, the inside of the turntable 2 is slidingly installed with the connecting rod 3, and the inside of the connecting rod 3 is provided with a magnet 302 The opposite surface of the magnet 302 is provided with a corresponding coil 301 inside the turntable 2. The magnetic poles of the magnetic field generated by the outer end of the coil 301 are the same as the magnetic poles of the opposite magnet 302, and the coil 301 is electrically connected to the variable resistor 1402. The position of the metal sheet 1401 and the variable resistor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com