An automatic packaging process method and device for inner packaging of igniter-like pyrotechnic products

A technology for automatic packaging and pyrotechnics, which is applied in the directions of automatic packaging control, packaging, and transportation packaging, etc., can solve the problems of weak intrinsic safety, low packaging efficiency of pyrotechnics, and low reliability of manual operation quality, and achieve strong Promote and demonstrate the effect of improving the leanness of packaging production and avoiding direct contact with explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

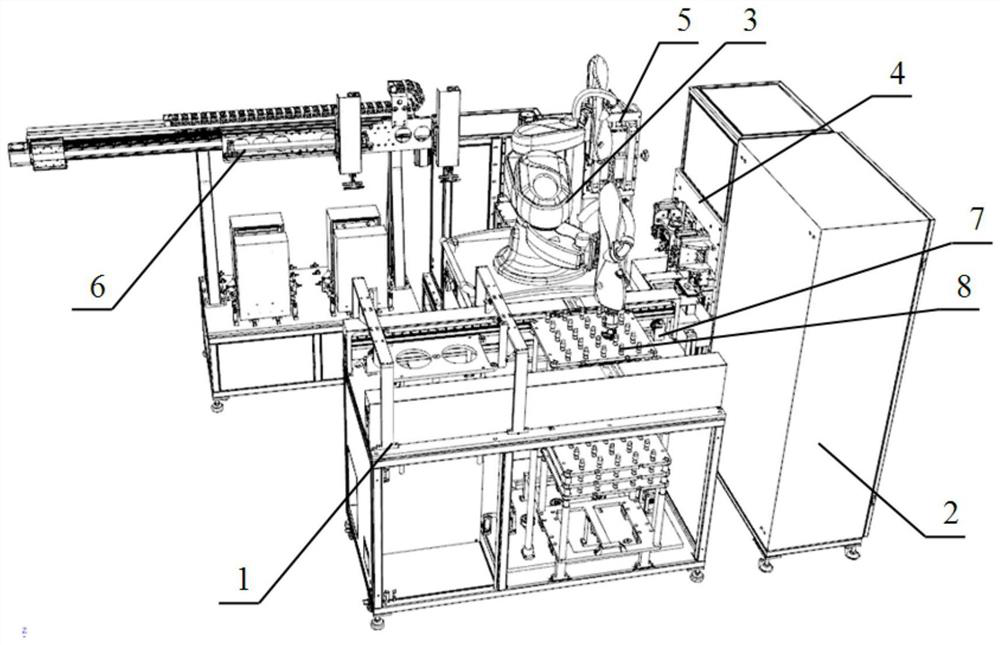

[0040] An automatic packaging process and device for the inner packaging of igniter-like pyrotechnic products, see image 3 As shown, its structure includes an automatic feeding module 1, an electrical control module 2, an automatic product feeding and turnover module 3, an automatic bagging module 4, an automatic bagging module 5, and an automatic sealing module 6. The finished parts 8 of pyrotechnic products such as igniters are loaded to the automatic feeding module 1 in the form of a whole plate, and then transferred to the automatic bagging and wrapping module 4 through the automatic product feeding and turnover module 3 to complete the bagging and wrapping of the igniters. During the process, the code scanner 7 is used to quickly identify the identity information of the finished pyrotechnic product 8 by rotating the code. The automatic product feeding and turnover module 3 transfers the finished bagged products to the automatic bagging module 5 to complete the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com