Sprayer and maintenance method thereof

A sprayer and spray nozzle technology, applied in the field of sprayer and its maintenance, can solve problems such as secondary pollution of cosmetics, and achieve the effects of reducing pollution, increasing service life and evenly dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

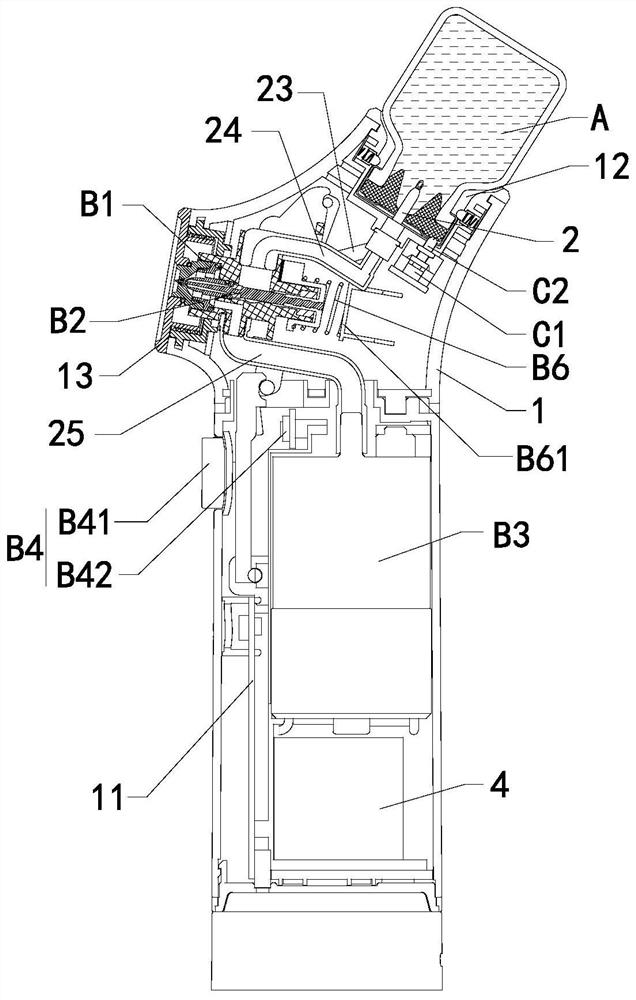

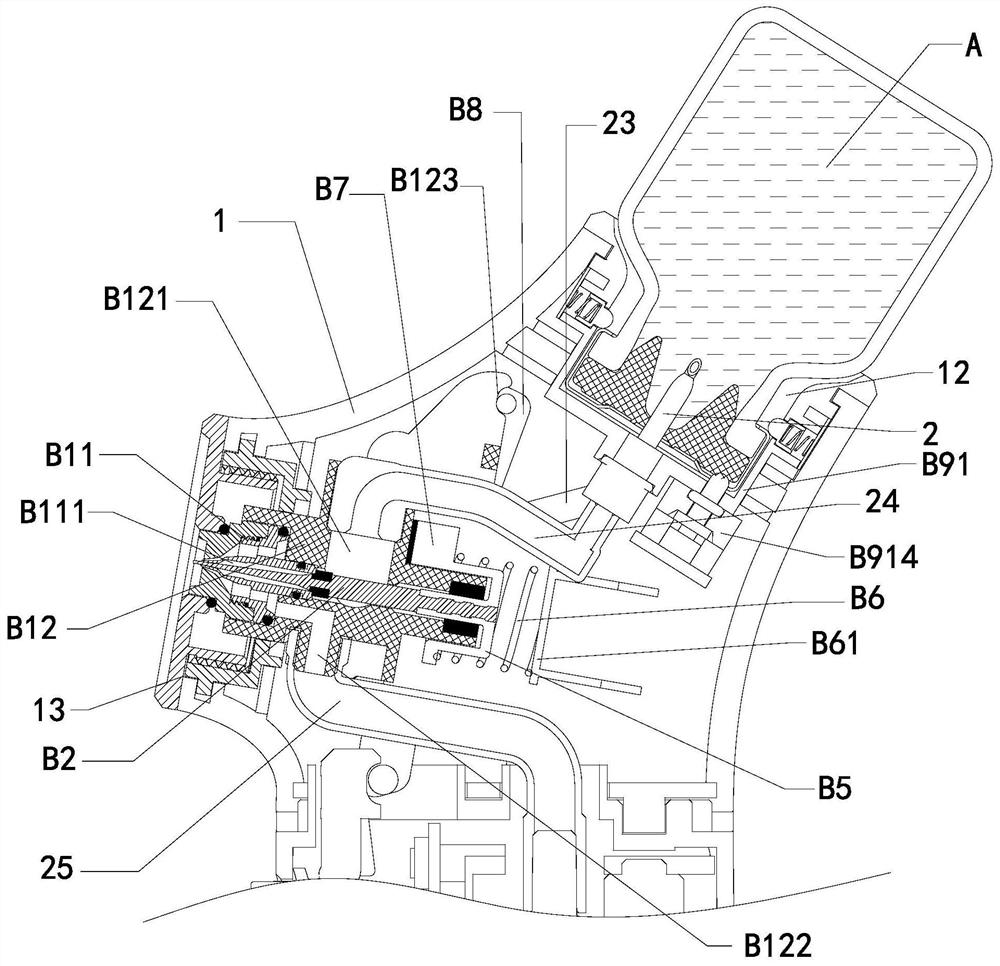

[0082] In the present invention, if Figures 10 to 11 Shown, also disclose a kind of maintenance method of above-mentioned sprayer, maintenance method comprises the following steps:

[0083] Step S1, take out the ampoule A, and put the disinfectant ampoule A11 into the installation port 12;

[0084] Step S2, start the sprayer to work and spray so that the disinfectant enters the liquid inlet channel 24 and the spray assembly, so as to sterilize the liquid inlet channel 24 and the spray assembly;

[0085] Step S3, after the spraying is completed, block the spray port B111, start the sprayer to work so that the disinfectant enters the ventilation channel 22 and the ampoule ventilation tube 23 to sterilize the ventilation channel 22 and the ampoule ventilation tube 23;

[0086] Step S5, open the spray port B111, start the sprayer to work and spray air.

[0087] In the above maintenance method, in order to prevent the sprayer from breeding bacteria after using it for a period of...

Embodiment 2

[0095] The difference between this embodiment and Embodiment 1 is that the maintenance method further includes step S4.

[0096] In the present invention, the maintenance method includes the following steps:

[0097] Step S1, take out the ampoule A, and put the disinfectant ampoule A1 into the installation port 12;

[0098] Step S2, start the sprayer to work and spray so that the disinfectant enters the liquid inlet channel 24 and the spray assembly, so as to sterilize the liquid inlet channel 24 and the spray assembly;

[0099] Step S3, after the spraying is completed, block the spray port B111, start the sprayer to work so that the disinfectant enters the ventilation channel 22 and the ampoule ventilation tube 23 to sterilize the ventilation channel 22 and the ampoule ventilation tube 23;

[0100] Step S4, an empty ampoule is installed at the installation port, the spray port B111 is blocked, and the sprayer is started to work so that the disinfectant in the liquid inlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com