Industrial wastewater treatment device and process

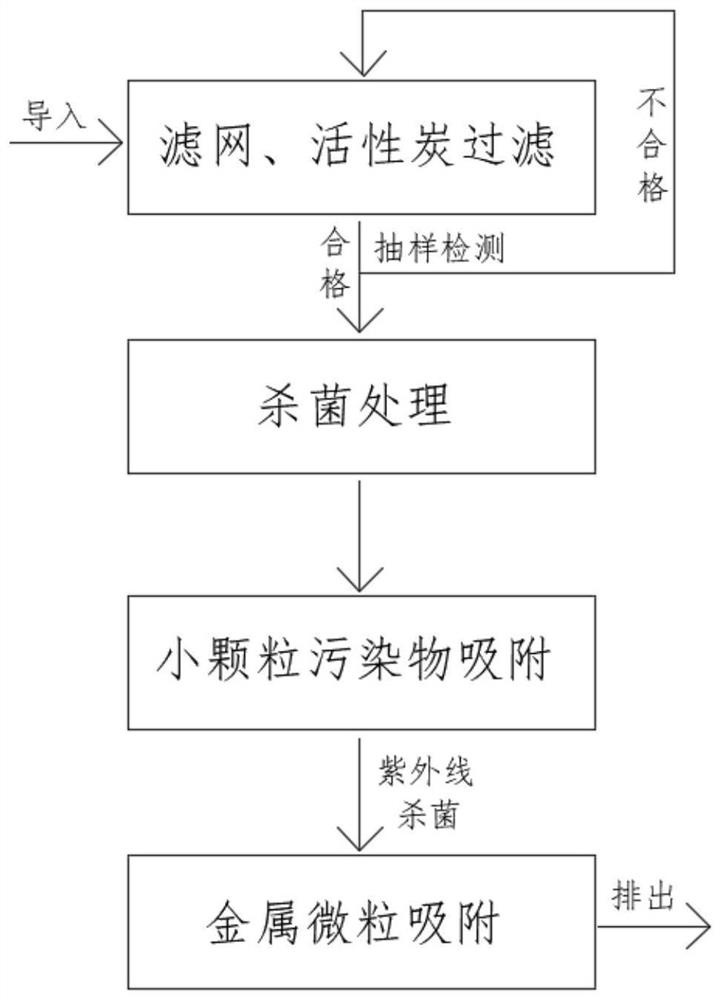

A technology for industrial wastewater and treatment equipment, which is applied in multi-stage water treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of real-time sampling detection without sampling function, inability to circulate and filter wastewater, and single sterilization method. , to achieve bactericidal effect Circular filtration, reduce tiny impurities, good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0038] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

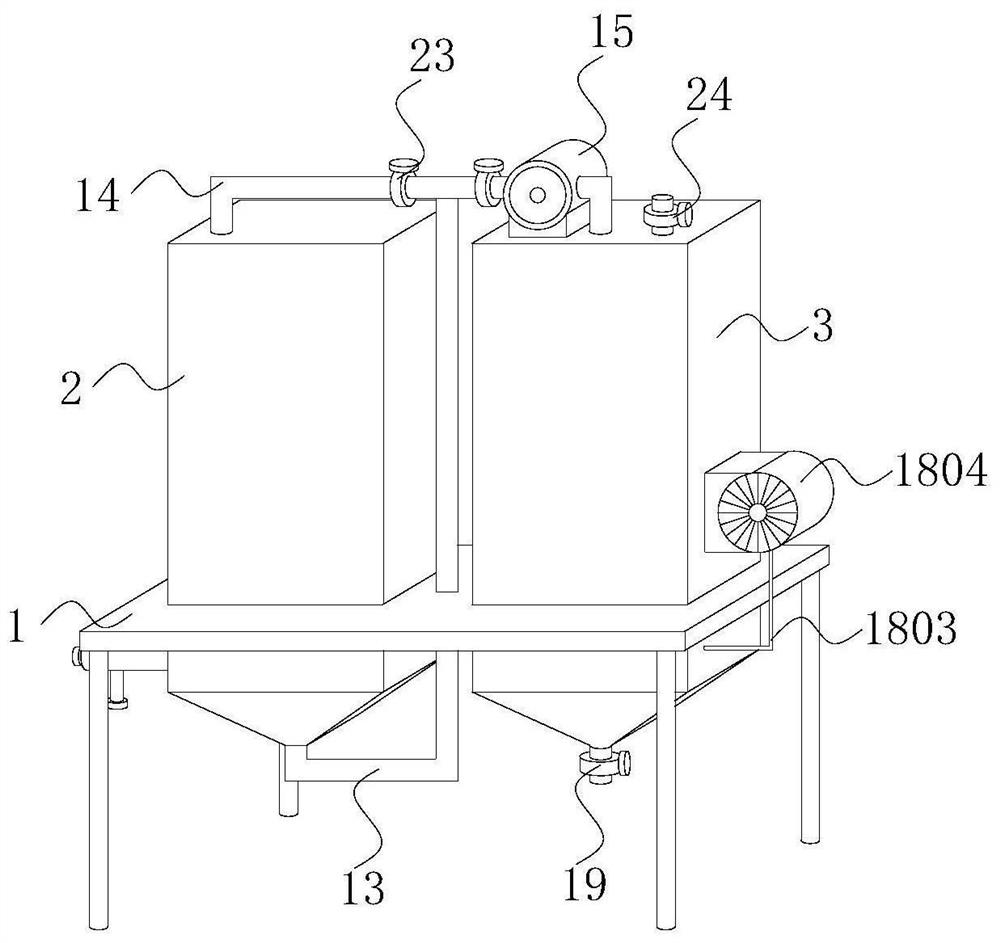

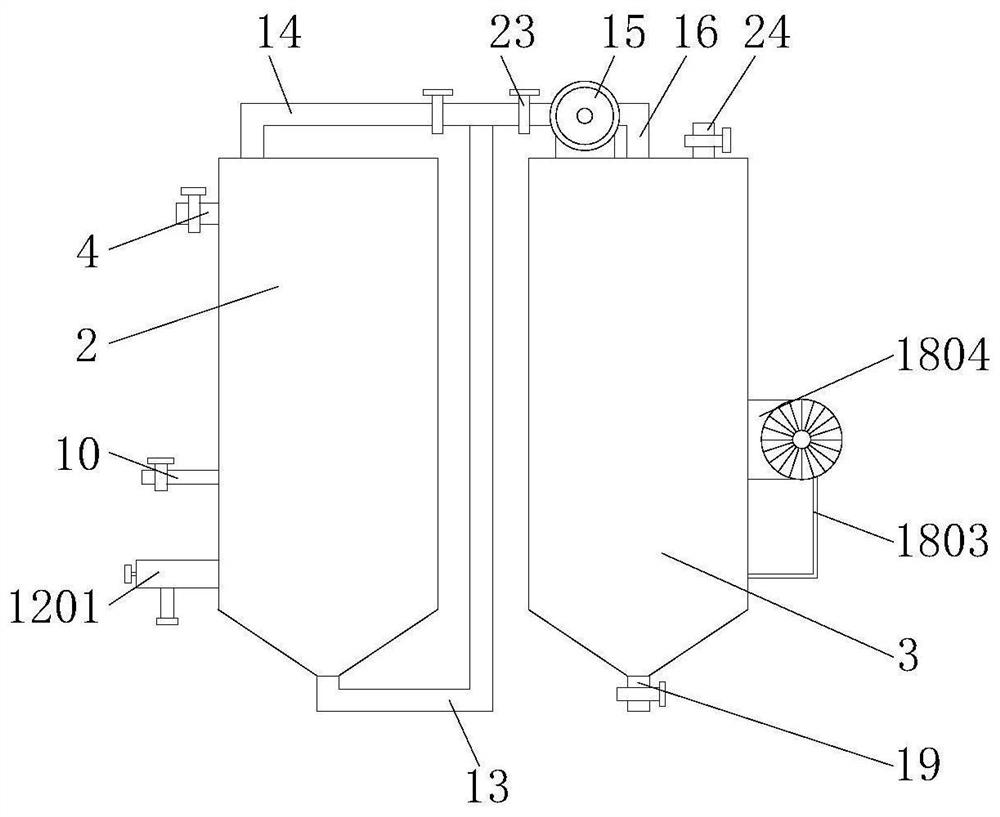

[0039] Such as Figure 1 to Figure 7As shown, a kind of industrial wastewater treatment equipment provided by the embodiment of the present invention includes a bracket 1, and the two sides inside the bracket 1 are respectively fixedly connected with a filter box 2 and a sterilization box 3, and the left side of the filter box 2 is connected with a water inlet pipe 4, The inner cavity of the filter box 2 is fixedly connected with a partition 5, and the top of the partition 5 is fixedly connected with the first filter screen 6, the second filter screen 7 and the activated carbon 8 in turn from left to right, and the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com