Fine down feather production process and device

A production process and production device technology, applied in the field of down production, can solve the problems of low efficiency, low efficiency, inconvenient operation of down sterilization, etc., and achieve the effects of improving efficiency, improving screening effect, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

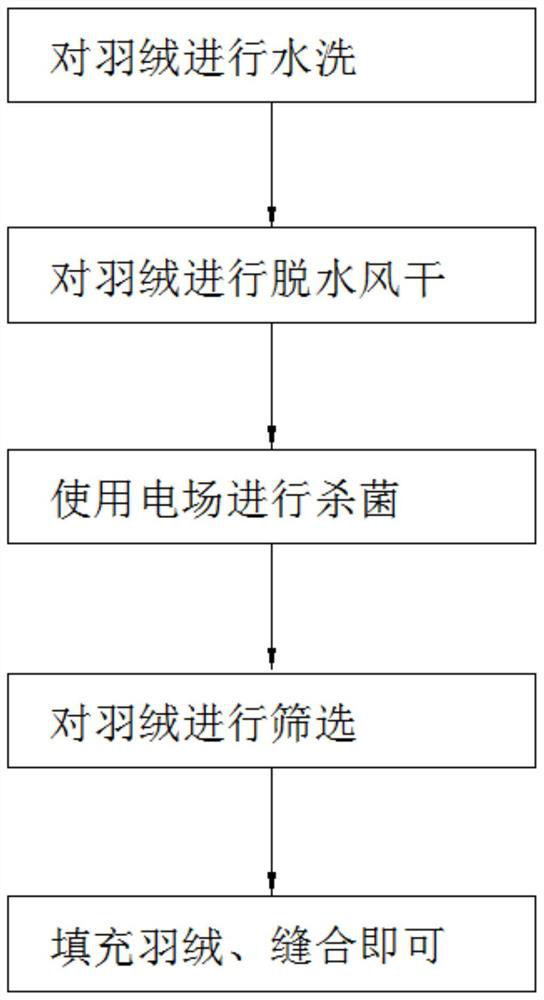

[0034] refer to Figure 1-5 , a fine down production process, comprising the following process steps:

[0035] S1: washing the down with water;

[0036] S2: dehydrating and air-drying the down;

[0037] S3: use electric field for sterilization;

[0038] S4: screening the down;

[0039] S5: Fill down and sew.

[0040] In this embodiment, in S1, a detergent and a deodorizing agent are added to the cleaning solution to clean the down.

[0041] In this embodiment, in S2, a dehydrator is used to dehydrate the down, and then a dryer is used to dry the down. The drying temperature is 35-45° C., and the drying time is 30-40 minutes.

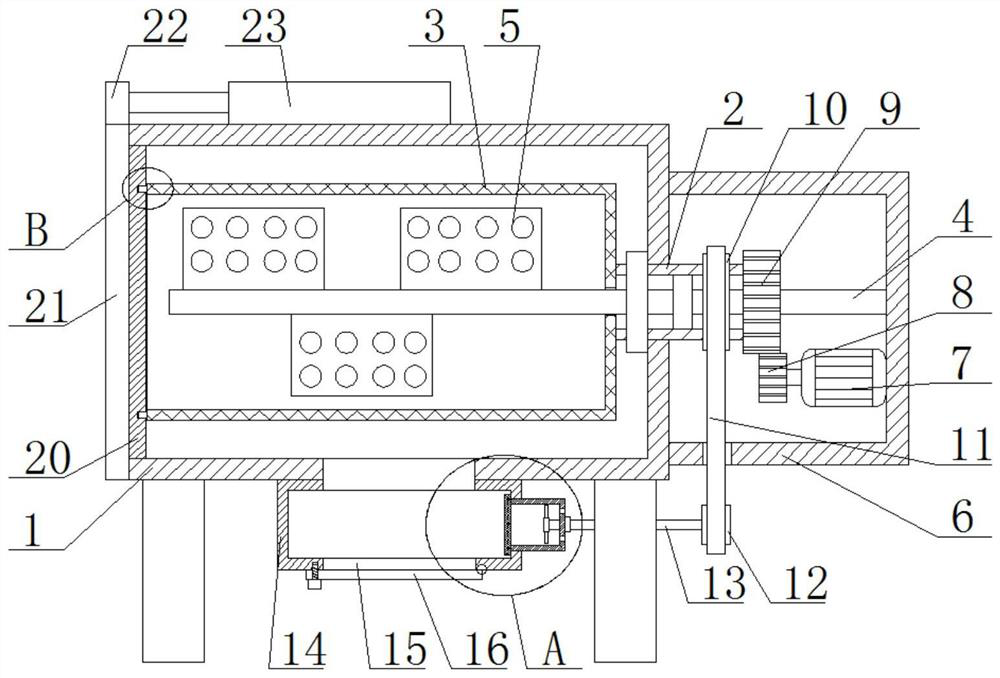

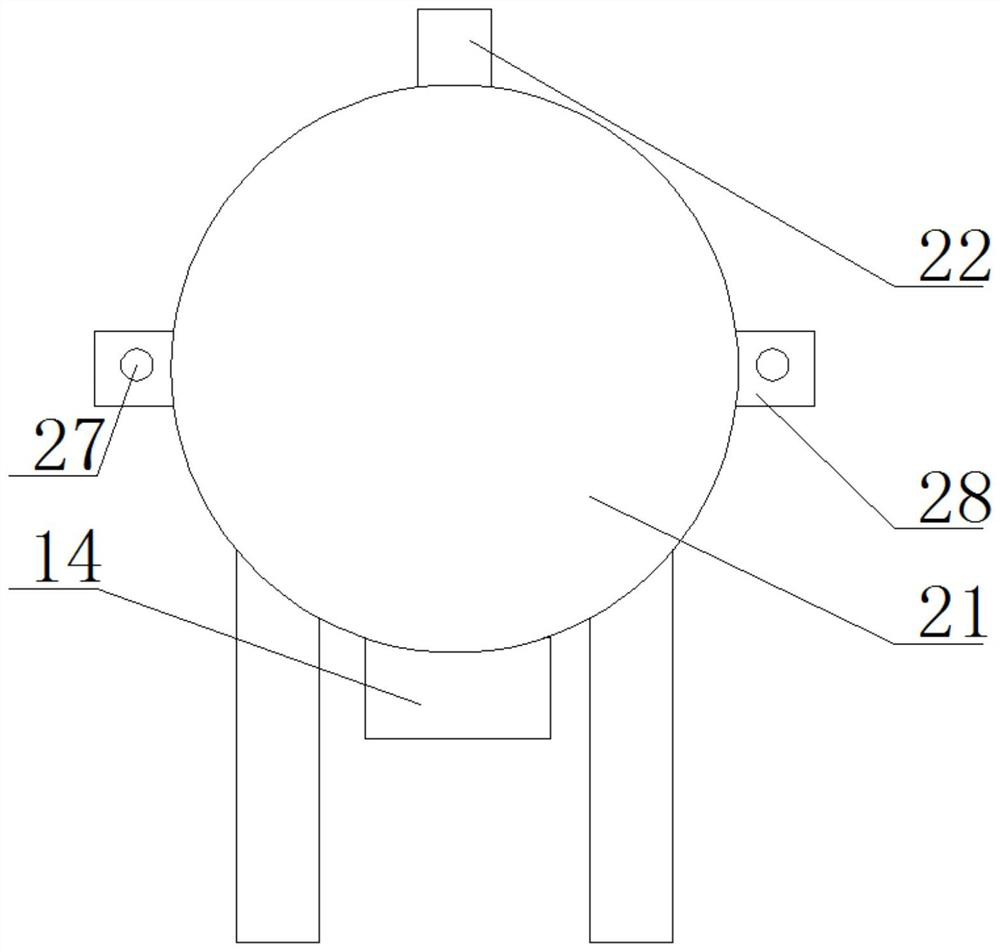

[0042] In this embodiment, S3 uses the transmission mechanism to transmit the down. Two electrode plates are placed on both sides of the transmission mechanism. One of the two electrode plates is a positive pole and the other is a negative pole. Sterilization, the transmission mechanism includes a transmission roller, a motor, and a conveyor belt. ...

Embodiment 2

[0050] refer to Figure 1-5 , a fine down production process, comprising the following process steps:

[0051] S1: washing the down with water;

[0052] S2: dehydrating and air-drying the down;

[0053] S3: use electric field for sterilization;

[0054] S4: screening the down;

[0055] S5: Fill down and sew.

[0056] In this embodiment, in S1, a detergent and a deodorizing agent are added to the cleaning solution to clean the down and down, and the down and down can be manually stirred during cleaning to improve the cleaning effect.

[0057] In this embodiment, in S2, a dehydrator is used to dehydrate the down, and then a dryer is used to dry the down. The drying temperature is 35-45° C., and the drying time is 30-40 minutes.

[0058] In this embodiment, S3 uses the transmission mechanism to transmit the down. Two electrode plates are placed on both sides of the transmission mechanism. One of the two electrode plates is a positive pole and the other is a negative pole. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com