Valve outer confluence hydraulic system and excavator

A hydraulic system and hydraulic technology, which is applied in the field of external confluence hydraulic system and excavator, can solve the problems of long oil flow distance, low energy utilization rate, large pressure loss, etc., and achieve small energy loss, high energy utilization rate, The effect of small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

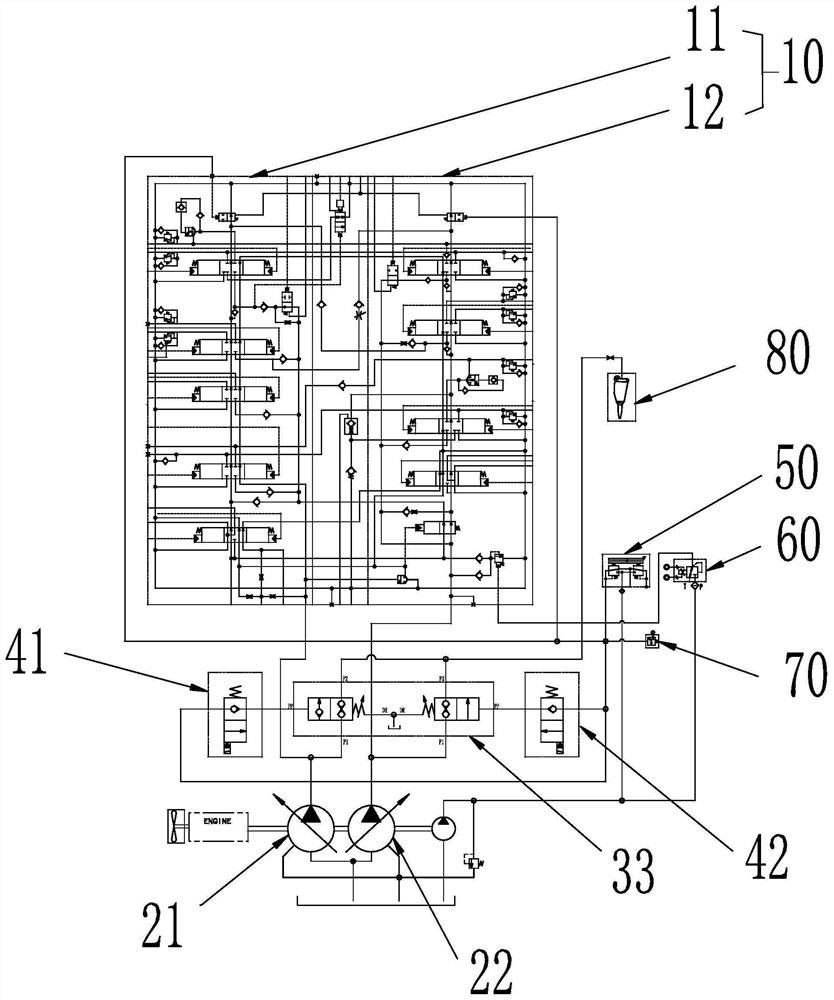

[0042] Please refer to Figure 1-Figure 4 , this embodiment provides an external valve confluence hydraulic system, which includes: a hydraulic energy supply module, a start module, a confluence module, a control module, a main valve 10 and a breaker 80, wherein:

[0043] The hydraulic energy supply module includes at least two hydraulic pumps, and each hydraulic pump can supply oil to the main valve 10;

[0044] The confluence module is connected in parallel with the main valve, and the confluence module is connected between the starting module and the breaker 80, and each hydraulic pump is connected with the confluence module;

[0045]The start-up module is connected to the confluence module through the control module. After the start-up module is started, the control module controls the confluence module so that n hydraulic pumps supply oil to the breaker 80 through the confluence module. n is a natural number, and n is greater than or equal to zero and less than or equal t...

no. 2 example

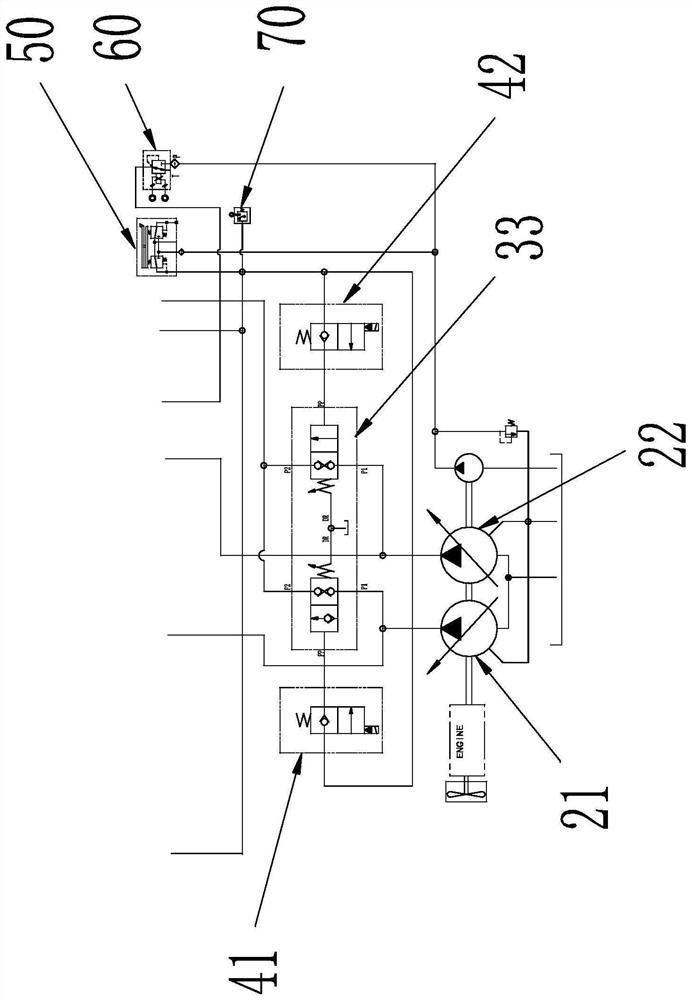

[0063] Please refer to figure 1 and figure 2 , this embodiment provides an out-of-valve confluence hydraulic system, which is an improvement on the basis of the out-of-valve confluence hydraulic system provided in the first embodiment above, and the technical content disclosed in the first embodiment will not be described repeatedly. The content disclosed in the example also belongs to the content disclosed in this embodiment.

[0064] In this embodiment, the confluence module includes a confluence valve group 33 , and each hydraulic pump communicates with the confluence valve group 33 . Specifically, the confluence valve group 33 includes a plurality of interconnected flow control parts, and each hydraulic pump communicates with a different flow control part, so as to individually control the output flow of each hydraulic pump through different flow control parts. Each flow control part communicates with the main valve 10 in parallel.

[0065] In this embodiment, the cont...

no. 3 example

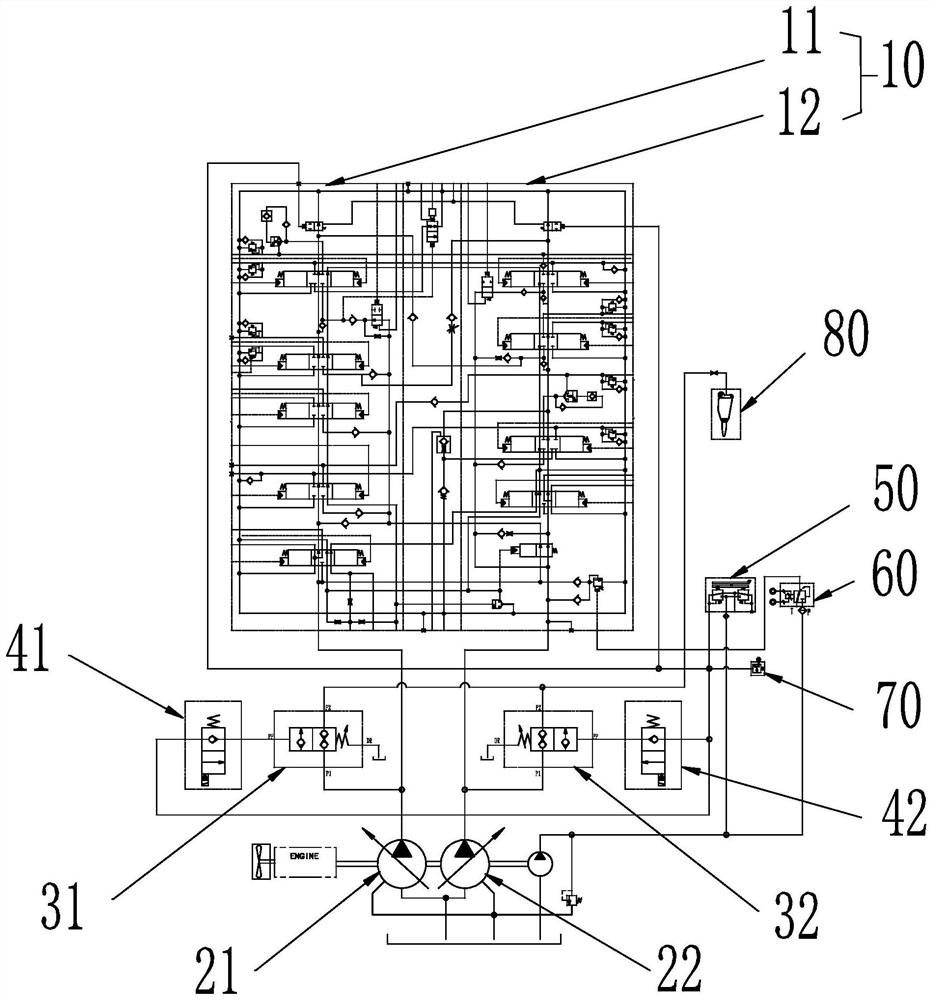

[0077] Please refer to image 3 and Figure 4 , this embodiment provides an out-of-valve confluence hydraulic system, which is an improvement on the basis of the out-of-valve confluence hydraulic system provided in the first embodiment above, and the technical content disclosed in the first embodiment will not be described repeatedly. The content disclosed in the example also belongs to the content disclosed in this embodiment.

[0078] In this embodiment, the confluence module includes at least two confluence valve blocks, the number of confluence valve blocks is the same as the number of hydraulic pumps, and multiple confluence valve blocks are connected to multiple hydraulic pumps in one-to-one correspondence.

[0079] A plurality of hydraulic pumps communicate with the main valve through the main valve pipeline respectively, and each confluence valve block is connected in parallel with the corresponding main valve pipeline. A plurality of confluence valve blocks can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com