Planetary roller rolling wheel trochoid curved surface composite transmission device

A planetary roller, compound transmission technology, applied in the direction of transmission, transmission parts, electromechanical devices, etc., can solve the problems of insufficient compact structure, heavy weight, low transmission precision, etc., and achieve simple and compact structure, convenient operation, and control precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

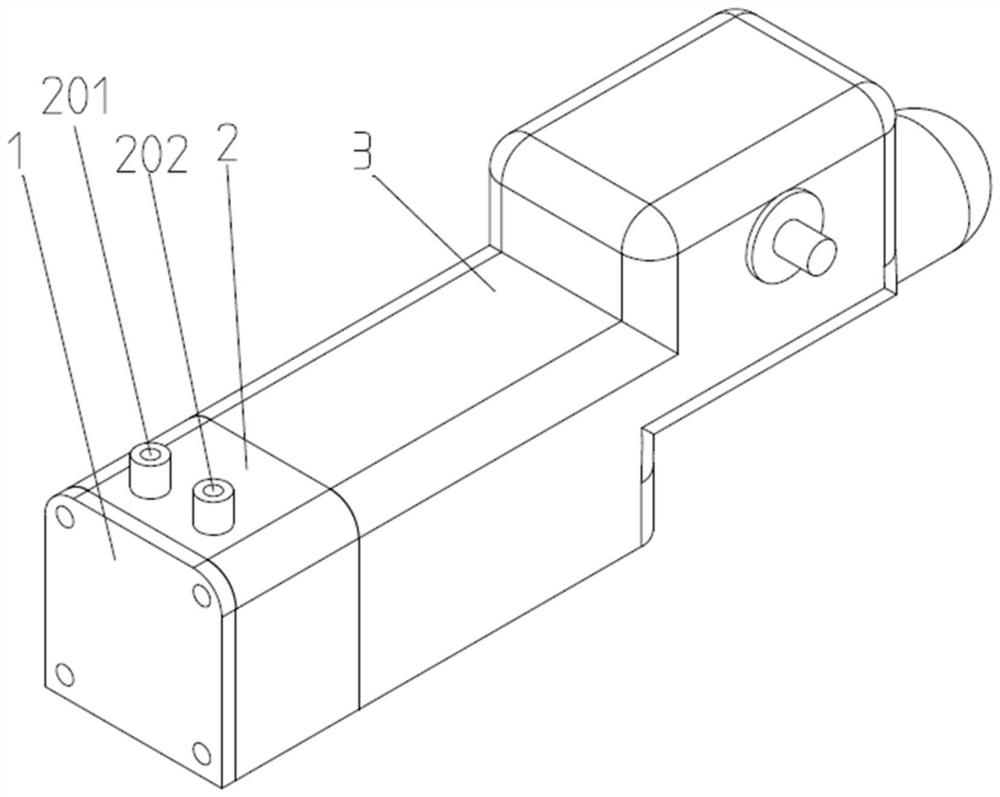

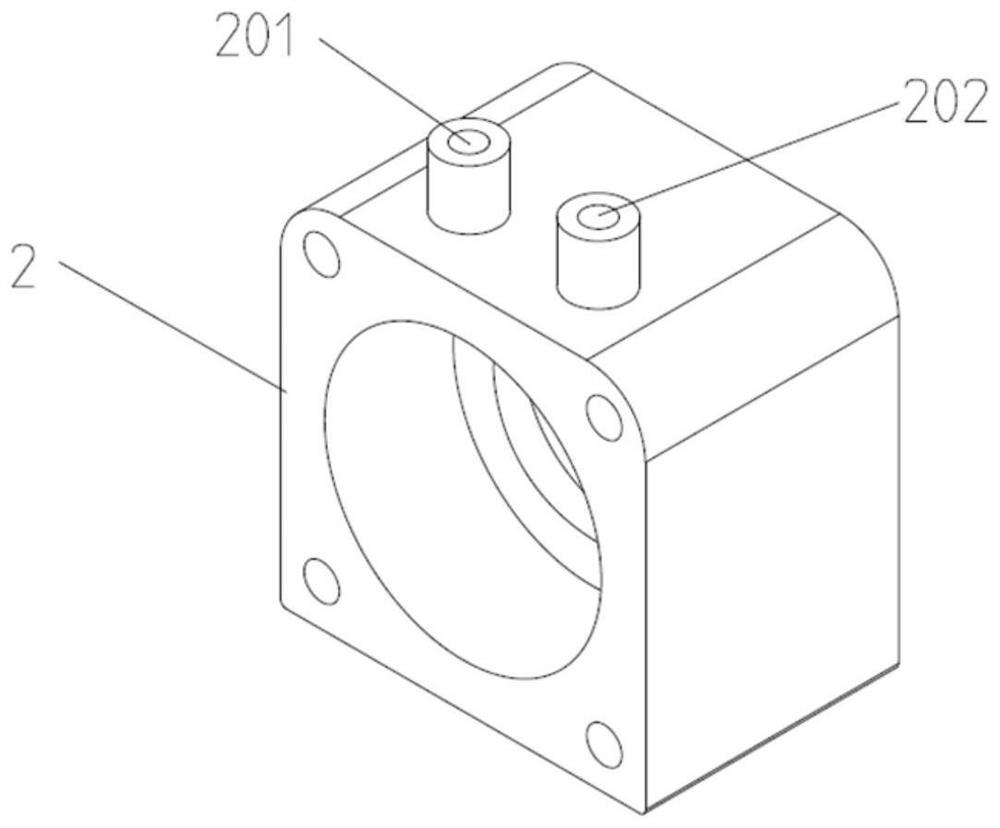

[0040] Refer to attached Figure 1-13 The planetary roller trochoidal surface compound transmission device shown includes a housing and a compound transmission device installed in the housing, and the compound transmission device includes a signal induction and output part, a planetary roller screw part and a trochoidal rack runner part, the signal induction and output part is detachably connected to one end of the planetary roller screw part, and the trochoidal rack runner part is connected to the planetary roller screw part The other end of the part is detachably connected, and the part of the planetary roller screw is provided with an anti-backlash assembly 18 .

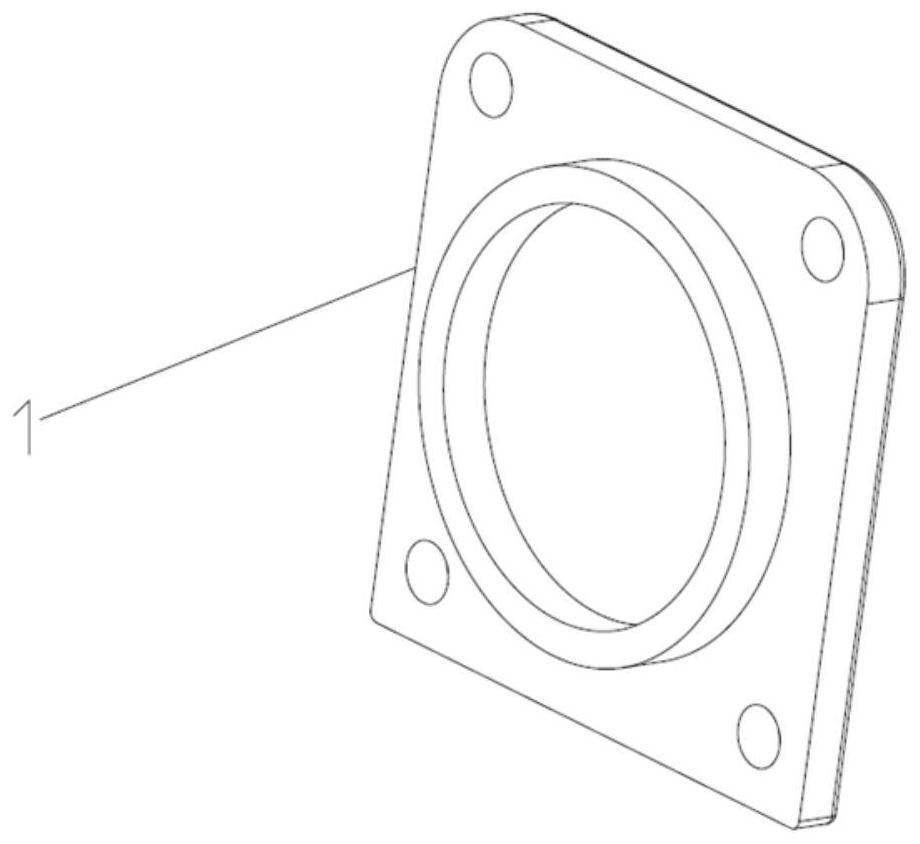

[0041]Specifically, the housing includes an end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com