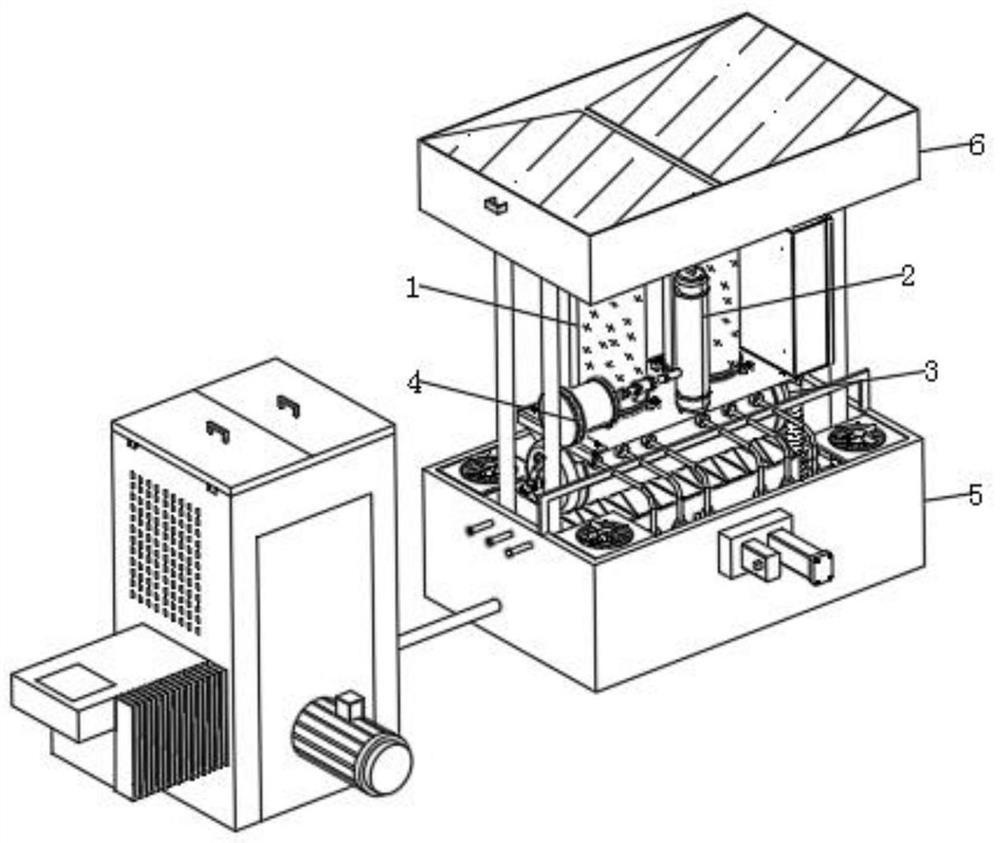

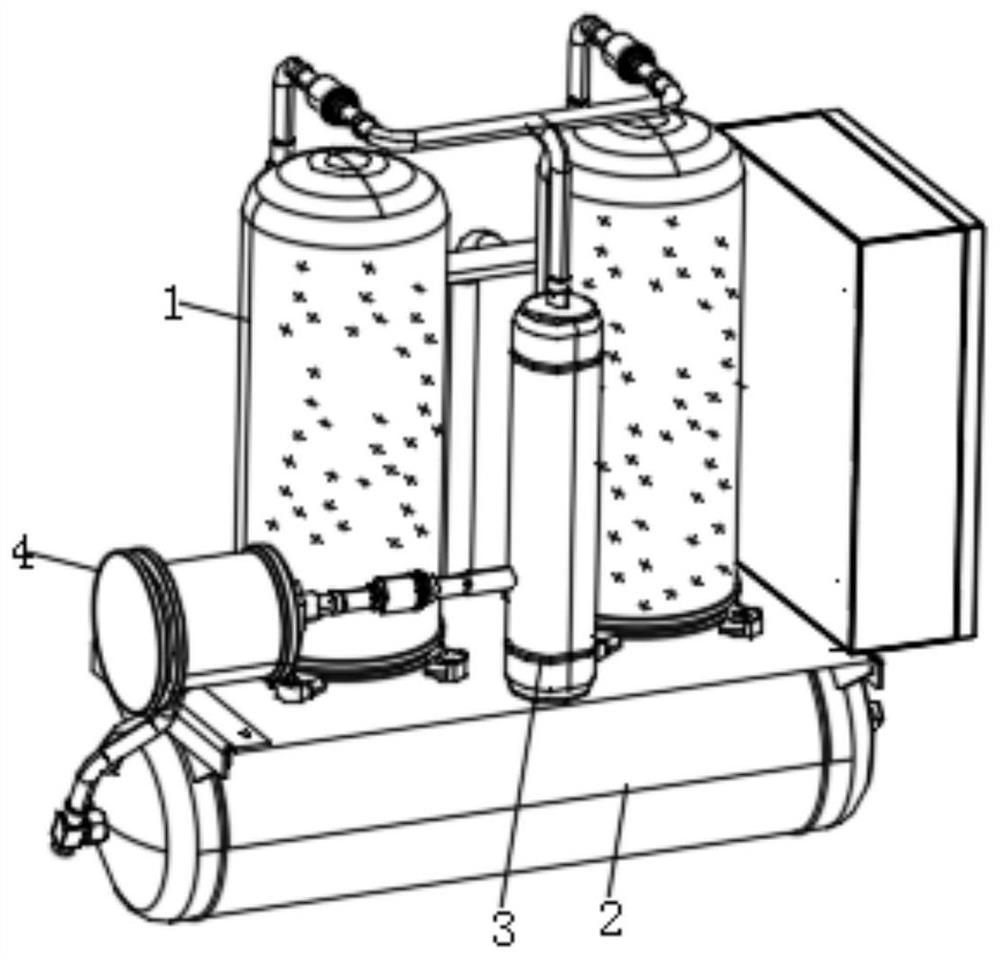

Double-compressor cold water heat pump unit

A dual-compressor and heat pump unit technology, applied in heat pumps, refrigeration components, refrigerators, etc., can solve the problems of heat pump unit parts that are easily damaged, heat pump unit vibration, and noise are difficult to eliminate, and achieve easy cleaning, waste reduction, and cooling effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

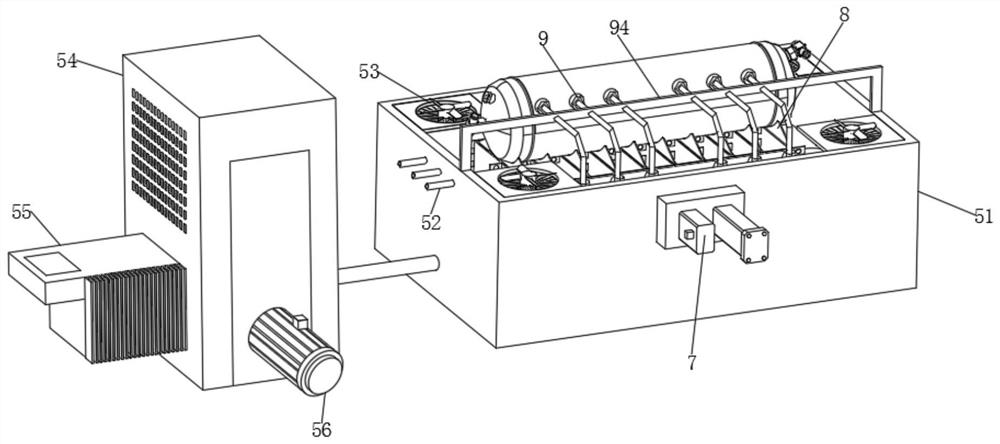

[0043] As an embodiment of the present invention, the spraying device 9 includes a miniature water pump 91, a fixed pipe 92, and a shower head 93. The water outlet of the water pump 91 is connected, and the shower head 93 is detachably installed on the rear end of the fixed pipe 92. The shower head 93 is located obliquely above the condenser 3, and the upper end of the side wall of the cooling pool 51 is fixedly connected with a support frame 94. The fixed pipe 92 runs through the inside of the support frame 94; during work, since the upper part of the condenser 3 cannot be in contact with water, the heat dissipation effect of the upper part of the condenser 3 is poor. 93 is sprayed out, and the cooling water is directly sprayed on the surface of the condenser 3, which is beneficial to the heat dissipation of the condenser 3 and can make the heat dissipation of the condenser 3 more uniform, and the fixing pipe 92 can be positioned by the support frame 94.

[0044] As an embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com