Drying device for lithium ion battery negative electrode material production

A lithium-ion battery and drying device technology, which is applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems of low drying efficiency and can not meet the needs of use, etc., so as to improve drying efficiency and improve condensation effect. , the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

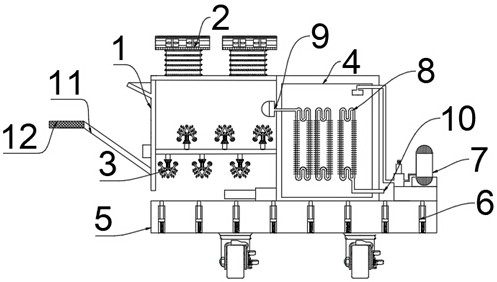

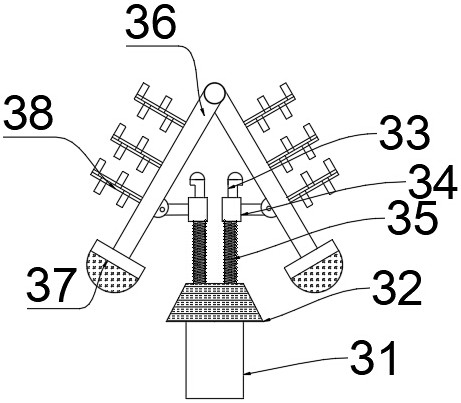

[0027] refer to Figure 1 ~ Figure 3 , a drying device for the production of lithium-ion battery negative electrode materials, comprising a bottom plate 5 and a stirring box 1 and a condensation box 4 fixedly installed above the bottom plate 5, a stirring shaft is installed on the inner wall of the stirring box 1, and the stirring shaft is fixed Several stirring devices 3 are installed, two drying devices 2 are arranged above the stirring box 1, the stirring device 3 includes a connecting block 31 fixedly installed on the stirring shaft, and an electromagnet is connected to the end of the connecting block 31 away from the stirring shaft 32, the end of the electromagnet 32 away from the connection block 31 is fixedly installed with two slide bars 33, and the two slide bars 33 are both sleeved with a magnet 34 and a spring 35, and the spring 35 is arranged between the magnet 34 and the electromagnet 32, The sides of two magnets 34 are connected with stirring rod 36 through con...

Embodiment 2

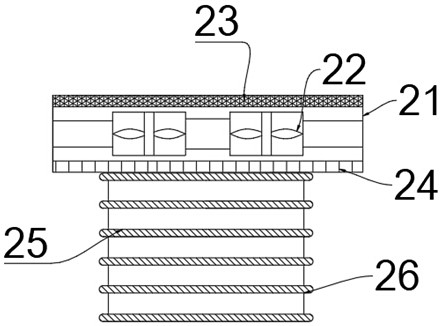

[0034] refer to Figure 4 , a drying device for the production of negative electrode materials for lithium-ion batteries. Compared with Embodiment 1, the side of the condensation pipe 8 is provided with several cooling teeth, and the side of the mixing box 1 is fixedly equipped with a handle 11. The handle 11 The side of the side is covered with anti-skid net 12, and the inside of the bottom plate 5 is provided with several shock absorbers 6, the shock absorber 6 includes a sleeve 61 fixedly installed on the inner bottom surface of the bottom plate 5, and the inner bottom surface of the sleeve 61 is fixedly installed with The second spring 63 , the end of the second spring 63 away from the inner bottom surface is connected with a slide block 62 slidably arranged inside the sleeve 61 , and a push rod 64 is connected above the slide block 62 .

[0035] Working principle: when in use, it is convenient to cool down the condensation pipe 8 by setting cooling teeth, and it is easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com