Test device for testing torque coefficient of oversized high-strength bolt

A technology for high-strength bolts and torque coefficients, which can be used to measure the direction of torque/torsion when tightening, and can solve problems such as low efficiency, high processing and installation requirements, and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

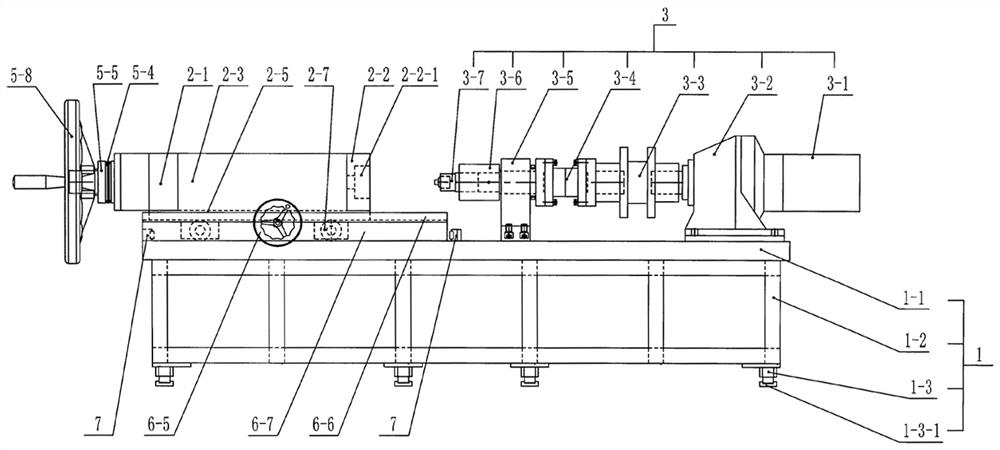

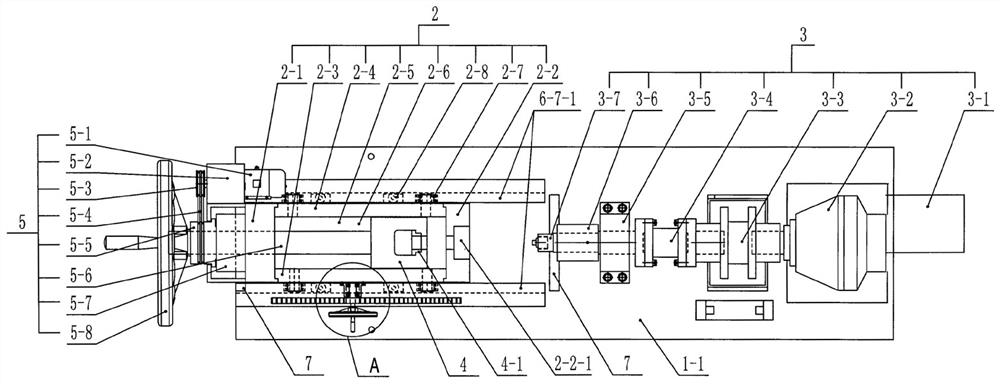

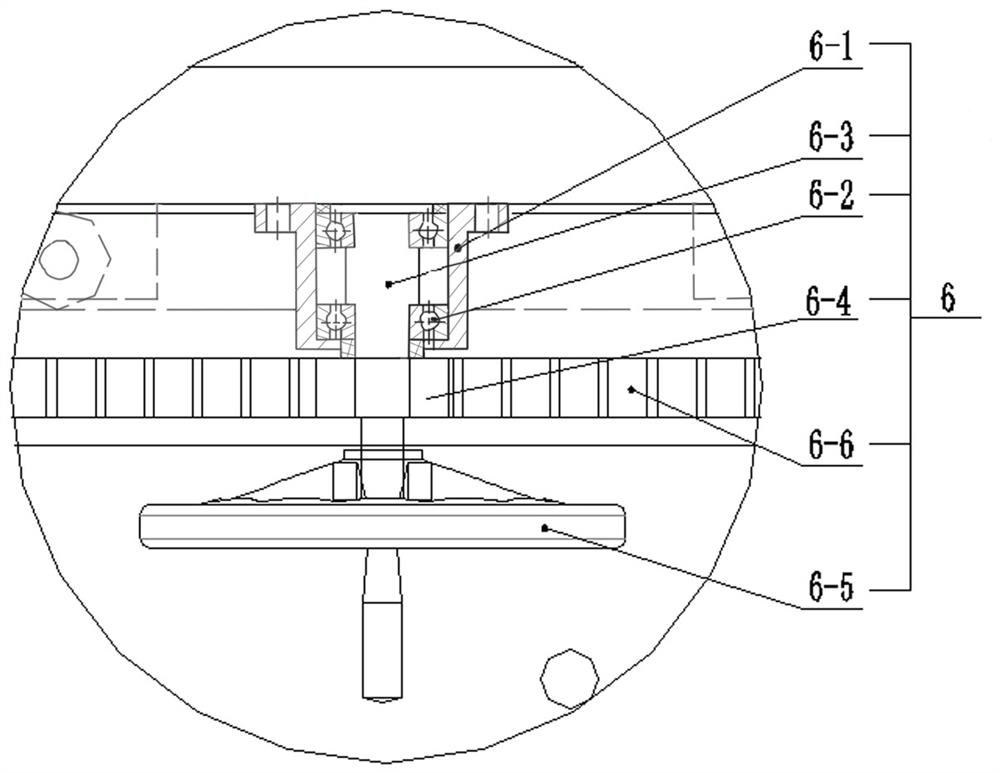

[0024] The present invention is further described below in conjunction with accompanying drawing:

[0025] like Figure 1 to Figure 3 As shown in the figure, a test device for testing the torque coefficient of super-large-sized high-strength bolts of the present invention includes a test platform 1 (which is the support foundation and plane reference of the present invention), corresponding to the reaction force frames seated at the front end and the rear end of the upper surface of the test platform respectively. 2 and the power loading device 3 (the reaction force frame 2 provides the support reaction force for the tested bolts, and the power loading device 3 provides the torsional power for the tested bolts), which are embedded in the inner cavity of the reaction force frame and can slide back and forth relative to each other. Head 4 (which can adapt to the test needs of different lengths and specifications of the tested bolts), is installed at the front end of the loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com