Scanning electron microscope sample table and sample preparation method thereof

A scanning electron microscope and sample stage technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as not easy to fix, break, and easily deform, and achieve the effect of protecting the electron microscope, improving contact, and ensuring that it is not damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

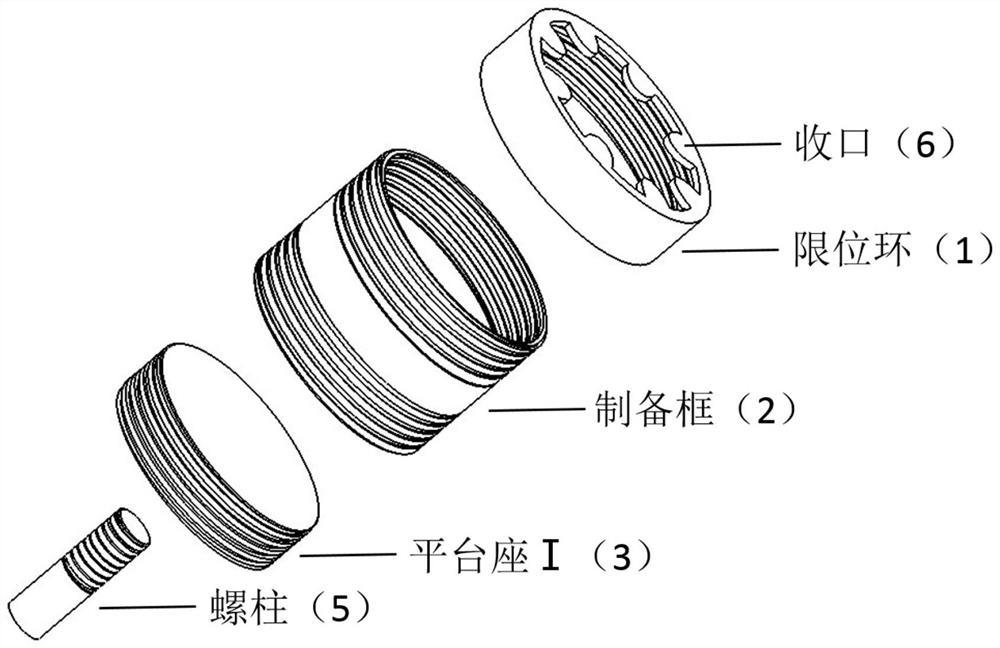

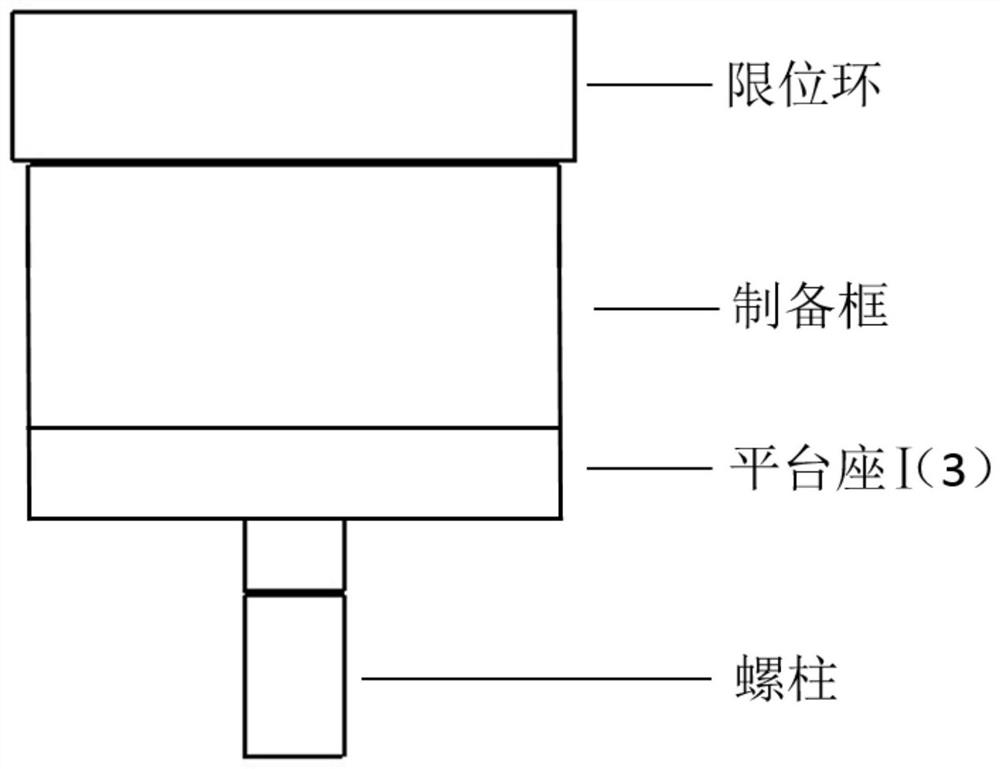

Embodiment 1

[0040] The limiting ring 1, the preparation frame 2, the platform seat I3 and the stud 5 are made of metallic copper.

[0041] The outer diameter of the limit ring 1 is 36mm, the inner diameter is 34mm, the mouth 6 is 8 claws, the claws protrude 3mm toward the center of the circle, the width of the claws is 2mm, and the thickness of the mouth is 1mm.

[0042] The inner diameter of the preparation frame 2 is 30mm, the outer diameter is 34mm, and the height is 20mm. The width of the thread at the upper and lower ends of the outer side is 2mm, and the width of the threaded opening at the upper and lower ends of the inner side is 6mm. The outer thread and the limit ring are assembled.

[0043] The thickness of the platform base I3 is 4mm, the diameter is 30mm, the inner diameter of the small hole in the bottom center is 3.2mm, and the depth of the internal thread is 3mm. The external thread on the edge is screwed into the assembly from one end of the preparation frame.

[0044] Th...

Embodiment 2

[0048] The limiting ring 1, the preparation frame 2, the platform seat I3 and the stud 5 are made of aluminum.

[0049] The outer diameter of the limit ring 1 is 16 mm, the inner diameter is 14 mm, the limit ring closing 6 is circular, the ring width is 2 mm, and the thickness of the closing part is 0.5 mm.

[0050] The inner diameter of the preparation frame 2 is 10mm, the outer diameter is 14mm, and the height is 10mm. The width of the external thread at the upper and lower ends of the outer side is 2mm, and the width of the inner thread at the upper and lower ends of the inner side is 3mm. The outer thread at one end is assembled with the limit ring 1.

[0051] The platform seat I3 has a thickness of 3 mm, a diameter of 10 mm, an inner diameter of the small hole in the bottom center of 3.2 mm, and an internal thread depth of 2 mm. The external thread on the outer edge of the platform is screwed in from one end of the preparation frame 2 for assembly.

[0052] The diameter o...

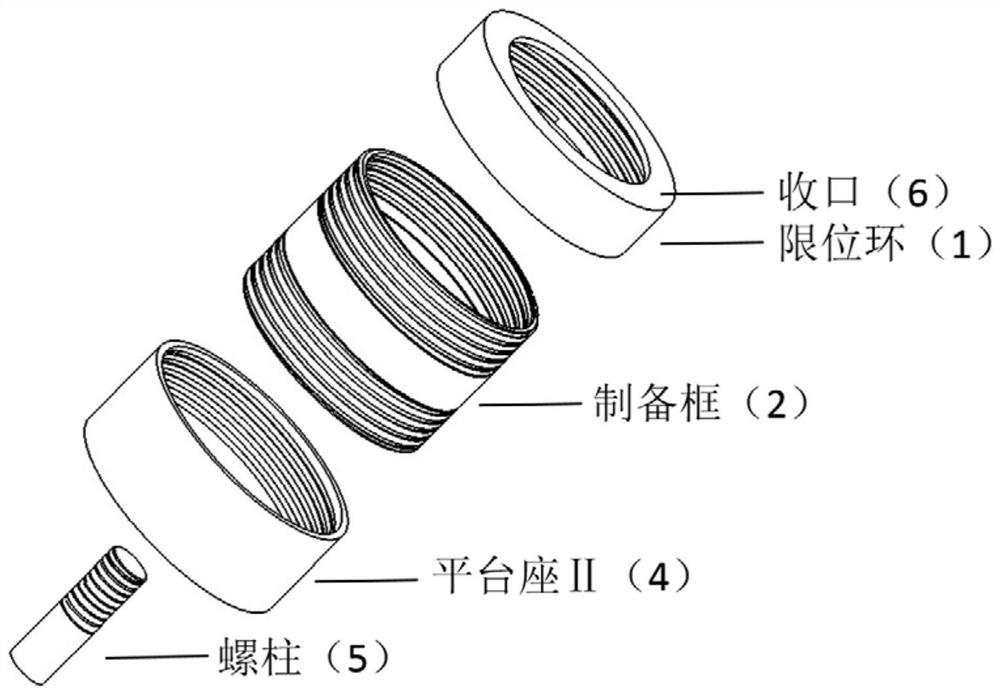

Embodiment 3

[0056] The limit ring 1, the preparation frame 2, the platform seat I3, the platform seat II4 and the stud 5 are made of metallic copper.

[0057] The outer diameter of the limiting ring 1 is 26 mm, the inner diameter is 24 mm, the closing 6 of the limiting ring 1 is 4 claws, the claws protrude 1 mm toward the center of the circle, the width of the claws is 1 mm, and the thickness of the closing part is 1 mm.

[0058] The inner diameter of the preparation frame 2 is 20mm, the outer diameter is 24mm, and the height is 15mm. The width of the external thread at the upper and lower ends of the outer side is 2mm, and the width of the inner thread at the upper and lower ends of the inner side is 5mm. The outer thread at one end is assembled with the limit ring 1.

[0059] The platform seat I3 has a thickness of 4mm, a diameter of 20mm, an inner diameter of the bottom center hole of 3.2mm, and an internal thread depth of 3mm. The external thread on the outer edge is screwed in from on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com