Humidity detector based on inverse magnetostriction effect

A technology of humidity detector and inverse magnetostriction, which is applied in the direction of material magnetic variable, etc., can solve the problems of small humidity detection range and low humidity detection sensitivity, and achieve the effect of high sensitivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

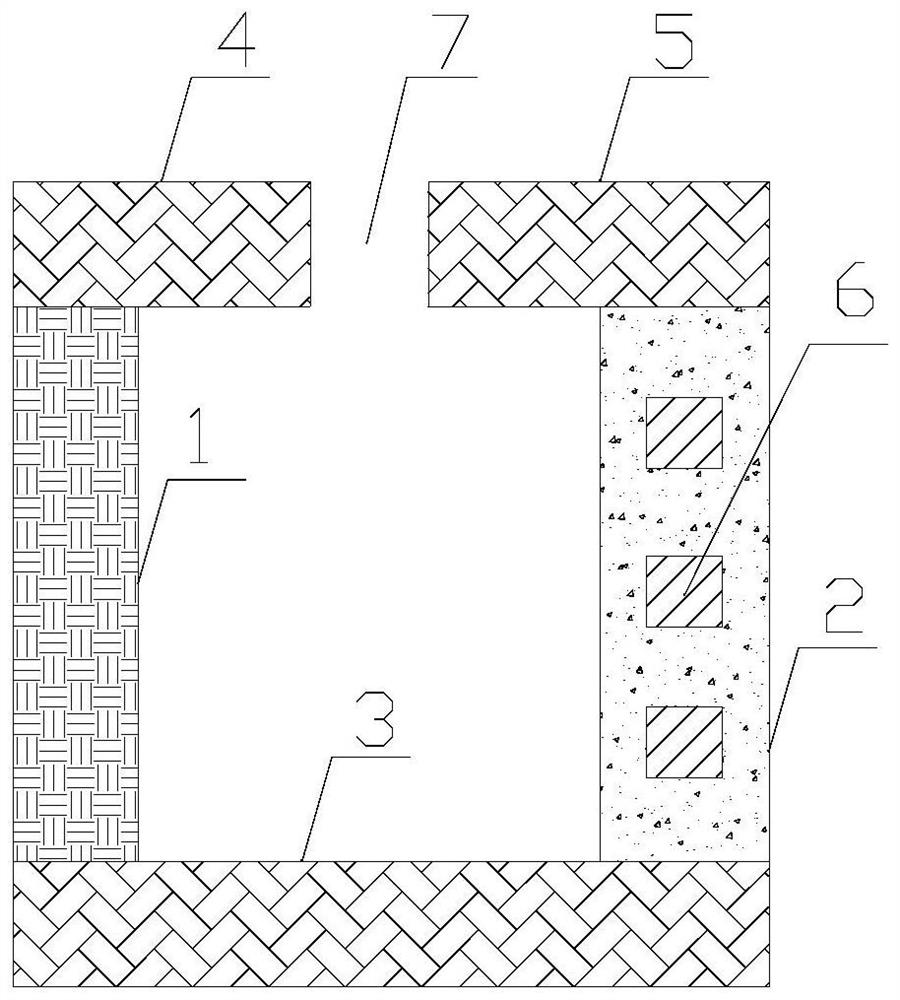

[0021] The invention provides a humidity detector with inverse magnetostrictive effect. Such as figure 1 As shown, the humidity detector based on the inverse magnetostrictive effect includes a magnet 1, a giant magnetostrictive material block 2, a first iron yoke 3, a second iron yoke 4, a third iron yoke 5, a groove 6, polyamide imine material. The material of the giant magnetostrictive material block 2 is a rare earth giant magnetostrictive material, and the electromechanical coupling coefficient of the rare earth giant magnetostrictive material is high. Preferably, the material of the giant magnetostrictive material block 2 is terbium dysprosium iron giant magnetostrictive material. The magnet 1 can be an electromagnet, that is, an electromagnet, or a permanent magnet, which is not limited here. Both ends of the magnet 1 are respectively connected to the first iron yoke 3 and the second iron yoke 4 . Such as figure 1 As shown, the two ends of the magnet 1 are perpendic...

Embodiment 2

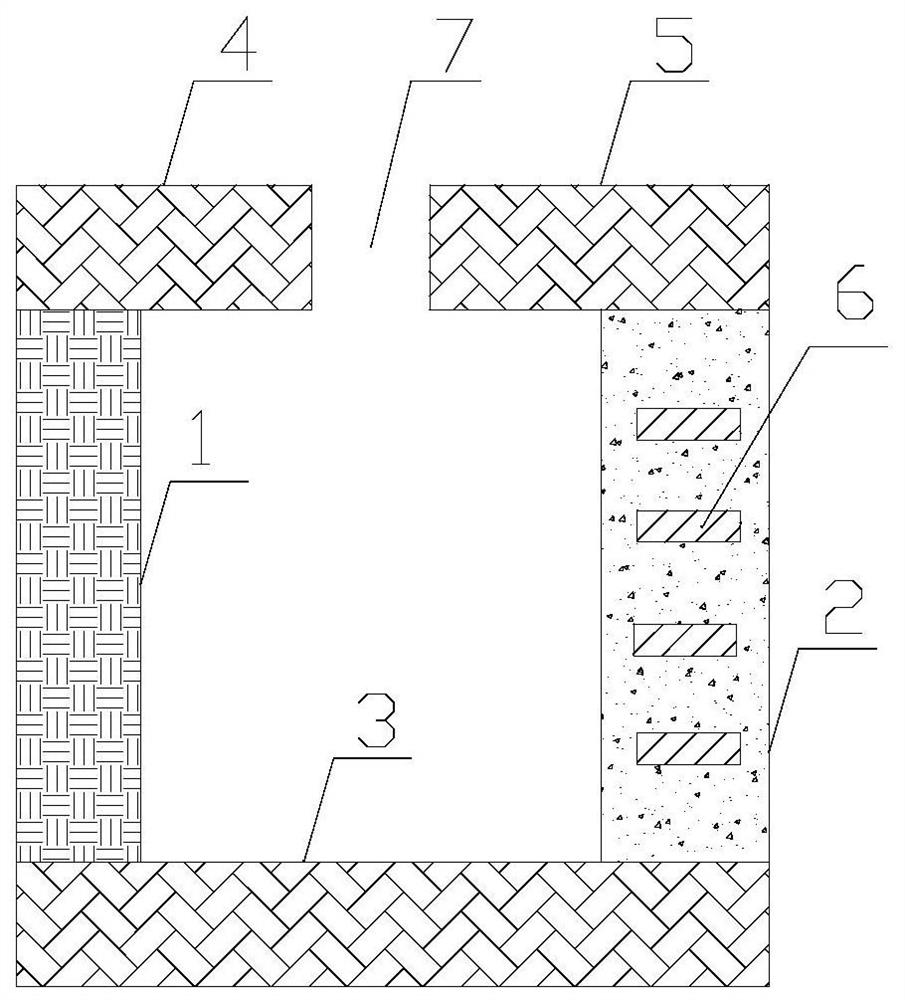

[0026] On the basis of Example 1, such as figure 2 As shown, the shape of the groove 6 is a rectangle, and the long side of the rectangle is perpendicular to the giant magnetostrictive material block 2 . In this way, the long sides of the rectangle block the magnetic circuit, and the magnetic circuit must be deflected along the direction perpendicular to the giant magnetostrictive material block 2, and after the deflection, it must be deflected along the direction of the giant magnetostrictive material block 2, thus significantly Increase the length of the magnetic circuit in the giant magnetostrictive material block 2, as mentioned above, this is conducive to the polyimide material to change the magnetic permeability of the giant magnetostrictive material block 2 more, thereby changing the gap 7 more The magnetic field at the place can improve the sensitivity of humidity detection. On the other hand, in the direction of the short side of the rectangle, the expansion of the ...

Embodiment 3

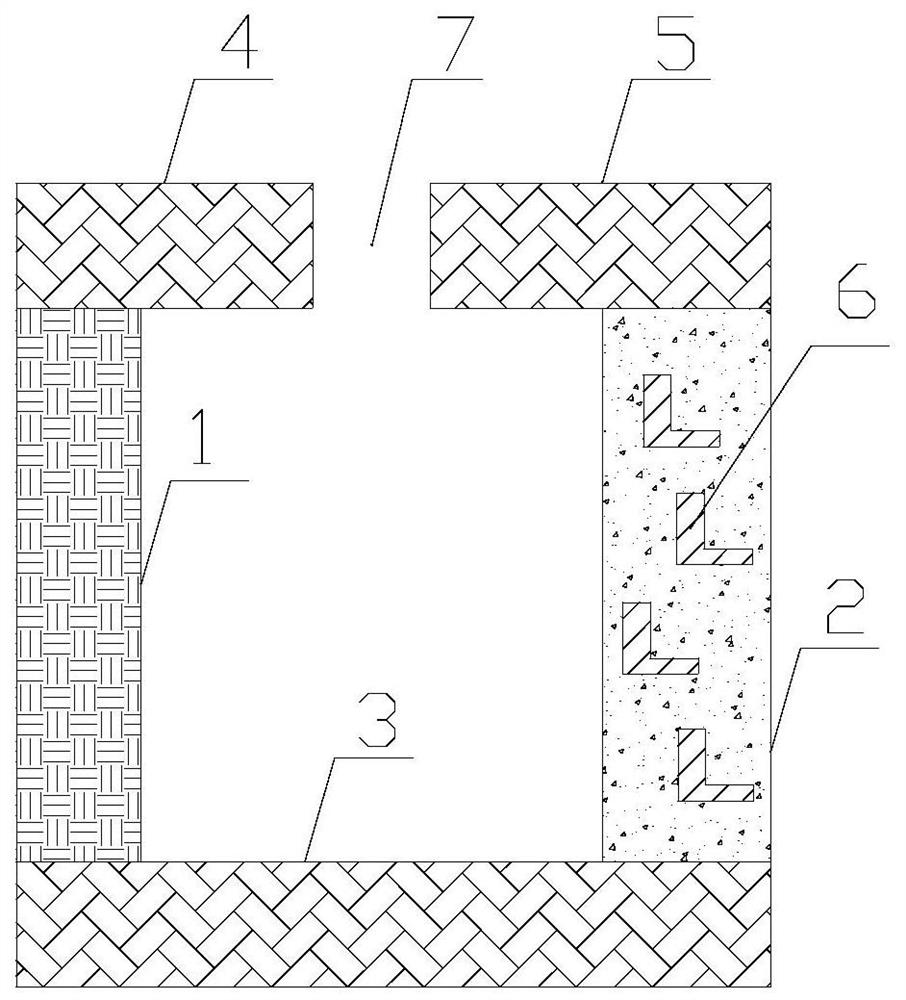

[0028] On the basis of Example 1, such as image 3 As shown, the shape of the groove 6 is a right-angle L shape, and one side of the right-angle L shape is perpendicular to the giant magnetostrictive material block 2 . In this way, the right-angle L-shaped groove 6 changes the magnetic field coupling in different directions in the giant magnetostrictive material block 2, and the expansion of the polyimide material in the groove 6 will change the giant magnetostrictive material block 2 more. The effective magnetic permeability inside, so as to change the magnetic field at the gap 7 more, so as to improve the sensitivity of humidity detection more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com