Production process and production equipment for compression spring

A technology for producing equipment and compression springs, applied in the field of compression spring processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

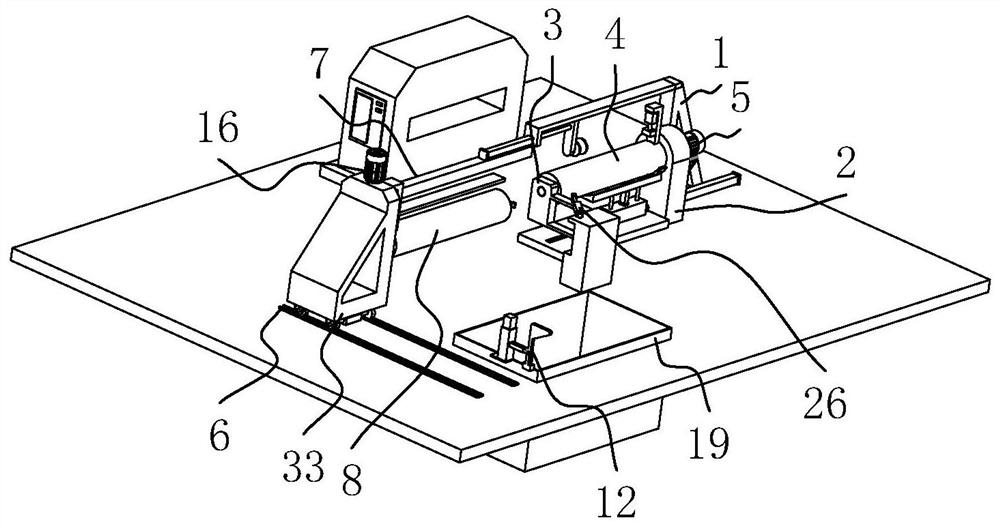

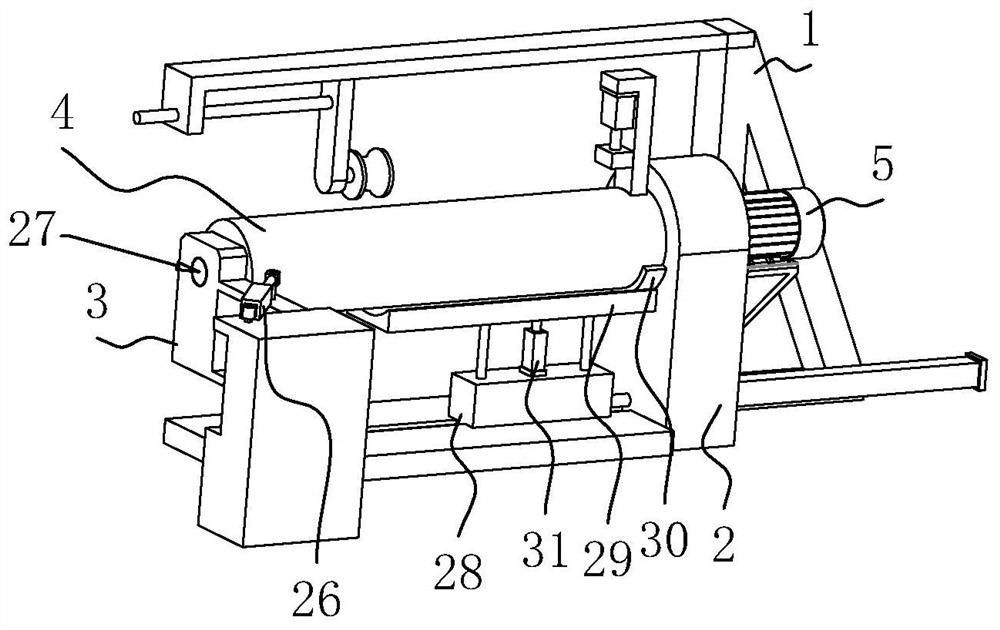

[0051] The embodiment of the present application discloses a production equipment of a compression spring. refer to figure 1 , a production process and production equipment of a compression spring include a winding device and a quenching device, the winding device includes a winding frame 1, a first bracket 2 fixedly connected with the winding frame 1, and a first bracket 2 movable with the winding frame 1 Two brackets 3 and a retrieving assembly for removing the spring; the first bracket 2 is rotatably connected with a winding roller 4 for spring forming, and the first bracket 2 is fixedly connected with a servo motor 5 that drives the winding roller 4 to rotate.

[0052] refer to figure 1 and figure 2 , the winding frame 1 is hinged with a first cylinder 26, the output end of the first cylinder 26 is hinged with the first bracket 2, the first bracket 2 is provided with a rotation hole 27 for the rotation of the winding roller 4, and the size of the end surface of the rota...

Embodiment 2

[0066] The embodiment of the present application provides a production process of a compression spring, including the following steps;

[0067] S1, forging; high temperature forging of spring steel;

[0068] S2; Rolling; the end of the spring is fixed to the winding roller 4 through the extrusion block, and one end of the spring steel is fixed to the winding roller 4, and the servo motor 5 controls the rotation of the winding roller 4, and under the guiding action of the guide wheel , the spring is just made into a spring during the rotation of the winding roller 4;

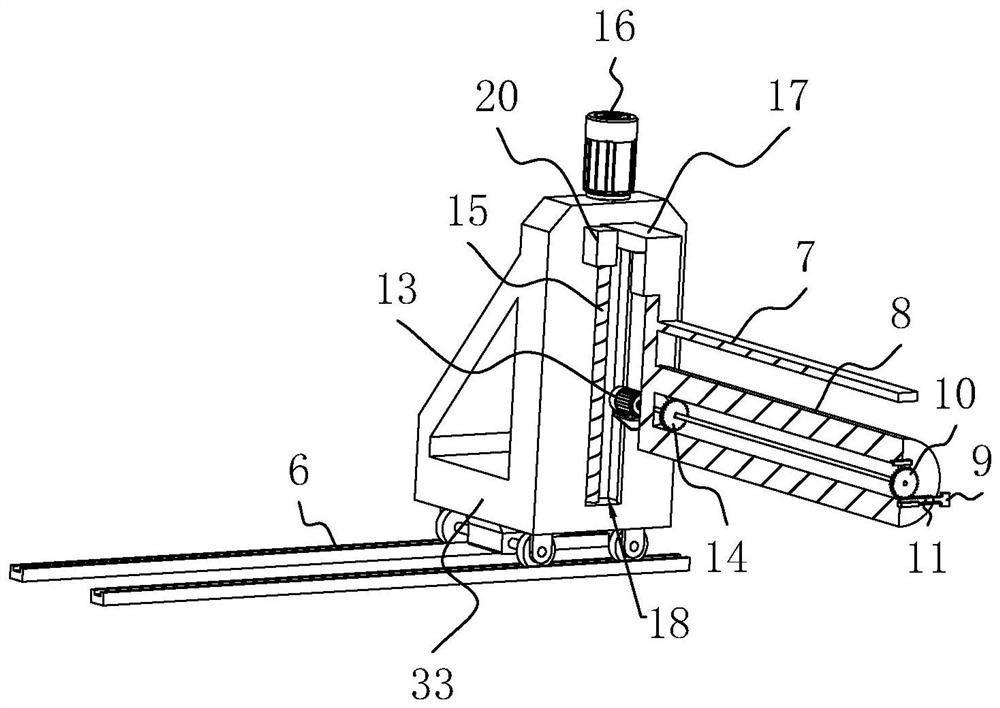

[0069] S3: transfer: the first cylinder 26 separates the second bracket 3 from the winding roller 4, and removes the spring from the winding roller 4 through the arc plate 30 and the support plate 29; the spring is sleeved outside the support column 8

[0070] S4; fixed; the first motor 13 drives the second gear 14 to rotate, the first gear 10 drives the two racks 11 to move away from each other, and the two lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com