Synchronous vibration back-up roll device with frame

A technology of synchronous vibration and supporting rolls, which is applied in the fields of metal solidification and continuous casting, and can solve problems such as no equipment structure scheme given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

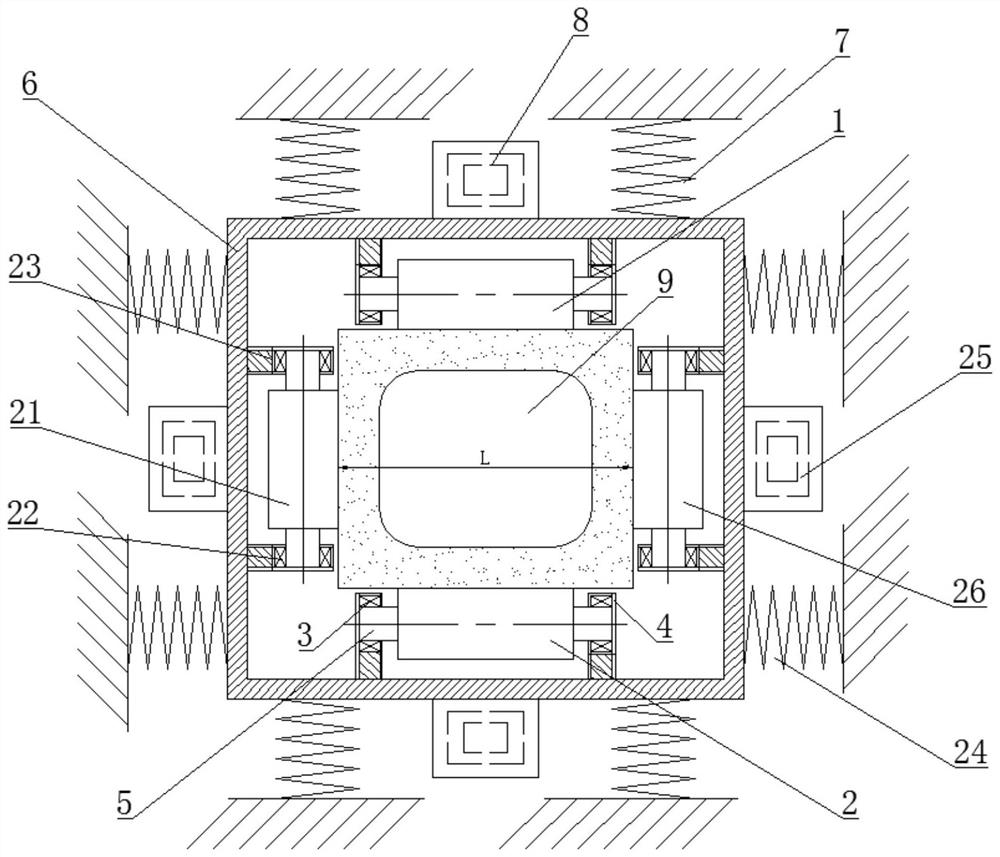

[0071] Vibration support rollers and vibration source bodies are arranged on the inner and outer arc directions of the slab

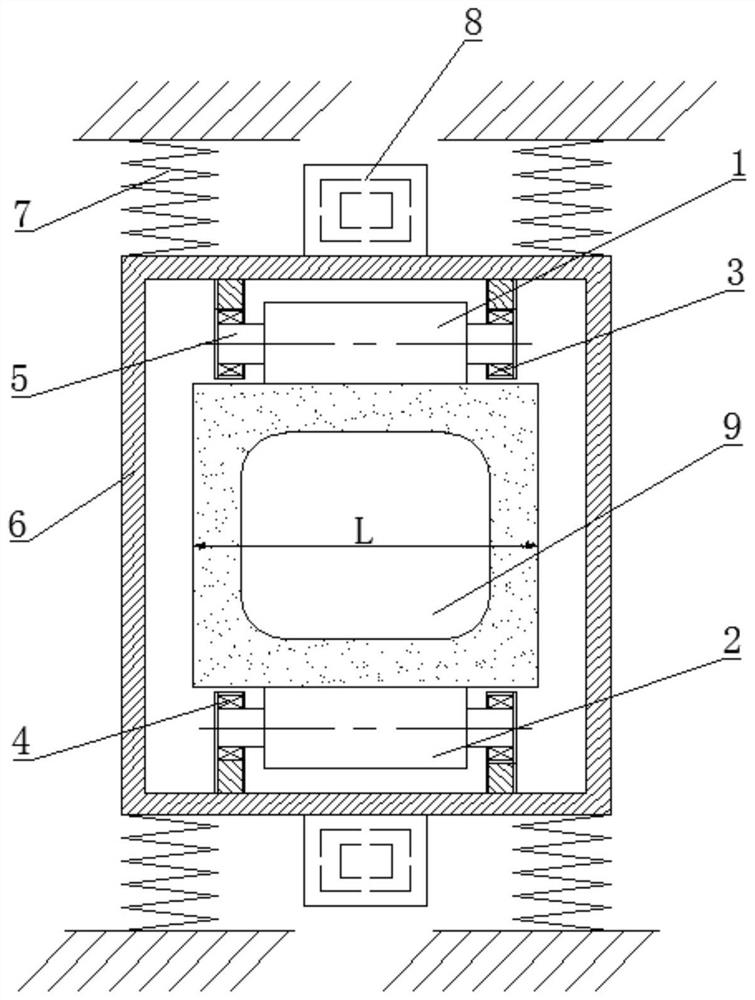

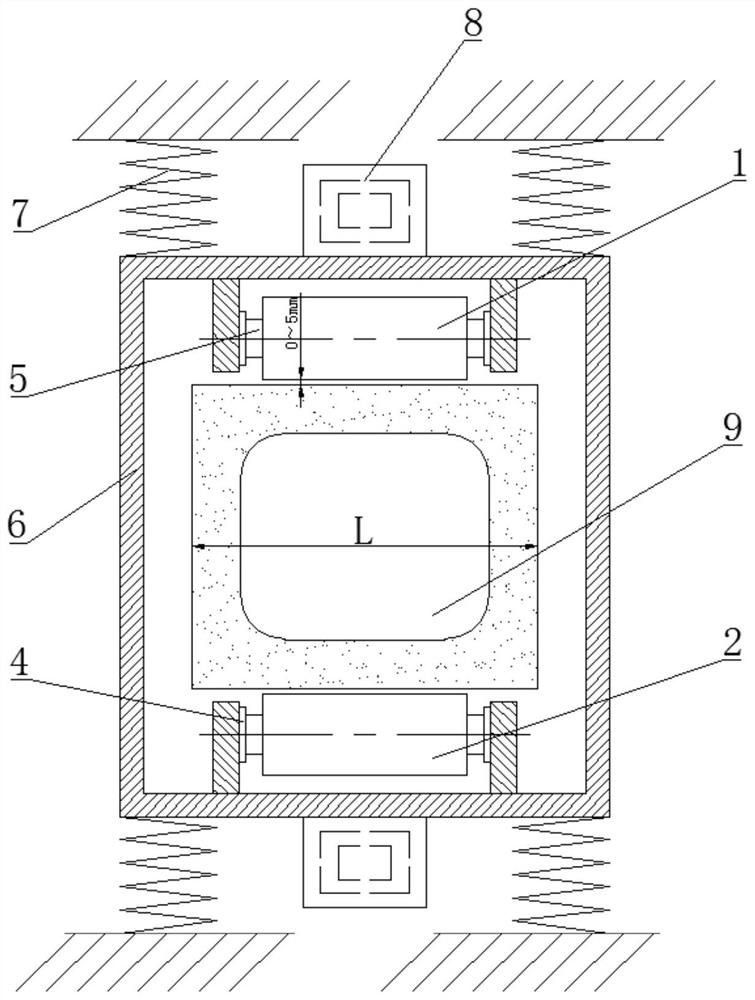

[0072] like figure 1 As shown, a synchronous vibrating support roll device with a frame includes: an inner arc vibrating support roll 1, an outer arc vibrating support roll 2, a first bearing 3, a first bearing seat 4, a support shaft 5, a vibrating frame 6, a first A spring 7, a vibration source body 8.

[0073]When in use, the vibration source body 8 driven by an external force drives the entire vibration frame 6 to vibrate, and the vibration is applied to the slab shell of the casting slab 9 through the vibration support rollers 1 and 2 .

[0074] The device can realize synchronous vibration in the direction of the inner and outer arcs of the casting slab, so that the thick central equiaxed crystals of the slab in the late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com