Chemical synthesis pharmaceutical wastewater solvent recovery method and device

A technology of pharmaceutical wastewater and recycling methods, which is applied in the field of water treatment and can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

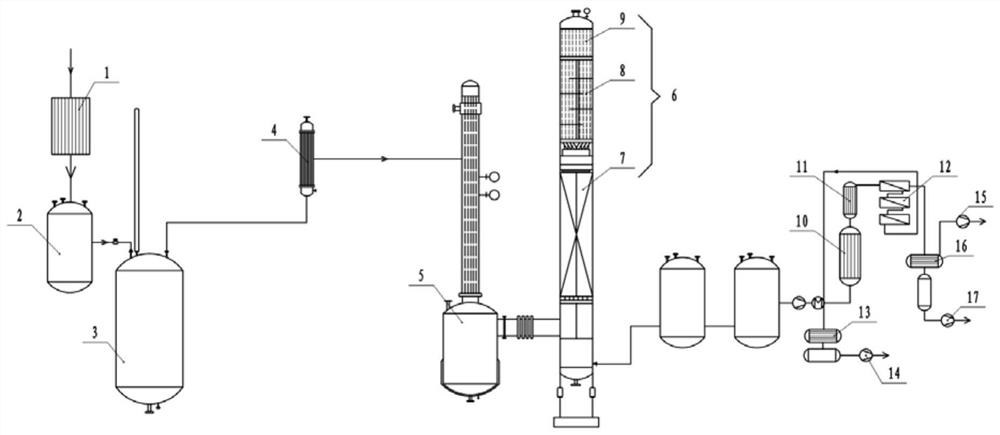

[0033] This embodiment is basically as attached figure 1 Shown: A chemical synthesis pharmaceutical solvent recovery wastewater treatment device, including a concentration unit, a rectification unit and a membrane separation unit.

[0034] The concentration unit includes a three-effect evaporator 1 and a degassing tower 2, and the three-effect evaporator 1 and the degassing tower 2 are connected by pipelines.

[0035] The rectification unit comprises mother liquor storage tank 3, preheater 4, falling film tower still 5 and rectification tower 6, also communicates with between mother liquor storage tank 3, preheater 4, falling film tower still 5 and rectification tower 6 Pipelines, and pipelines are also connected between the mother liquor storage tank 3 and the degassing tower 2; the top of the falling film tower reactor 5 in this embodiment is provided with a steam port, and the bottom end is provided with a hot water port, and the rectifying tower 6 is a multi-stage structur...

Embodiment 2

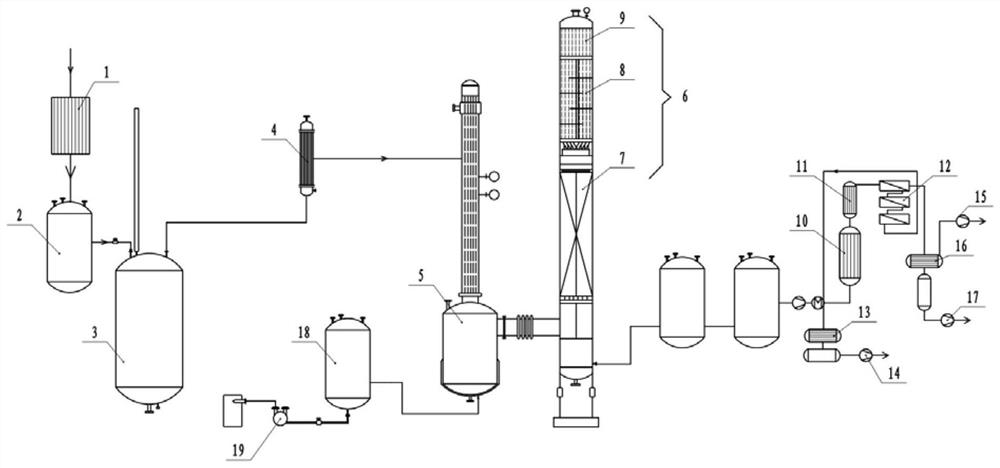

[0043] Such as figure 2As shown, the difference between this embodiment and the first embodiment is that in this embodiment, the hot water port is connected with a hot water tank 18 and a water circulation vacuum pump 19 . In this embodiment, the steam in the falling film tower kettle 5 will be condensed into liquid (hot water) after heat exchange, and will be discharged along the hot water outlet. The temporary heating of this part of hot water can be realized by the hot water tank 18 and the water circulation vacuum pump 19. storage and later recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com