A kind of electric furnace gunning material and gunning repair furnace protection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

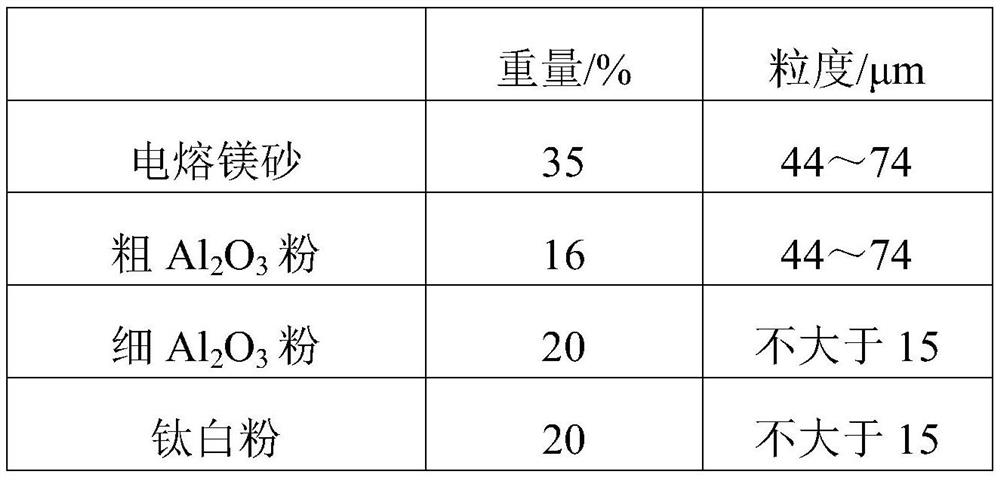

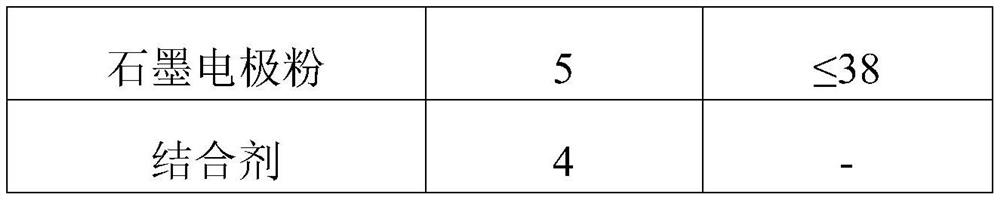

Embodiment 1

[0026]

[0027] Wherein, the binding agent is made up of the following components by weight ratio: phenolic resin 2%, coal pitch 4%, anthracene oil 2%.

Embodiment 2

[0032]

[0033] Wherein, the binding agent is made up of the following components by weight ratio: phenolic resin 2%, coal pitch 2%, anthracene oil 2%.

Embodiment 3

[0038]

[0039]

[0040] Wherein, the binding agent is made up of the following components by weight ratio: phenolic resin 2%, coal pitch 4%, anthracene oil 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com