A construction gap grouting device

A gap and construction technology, applied in the field of construction gap grouting device, can solve the problems of poor grouting applicability, cumbersome operation, large quantity, etc., and achieve the effects of ensuring stability, improving applicability, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

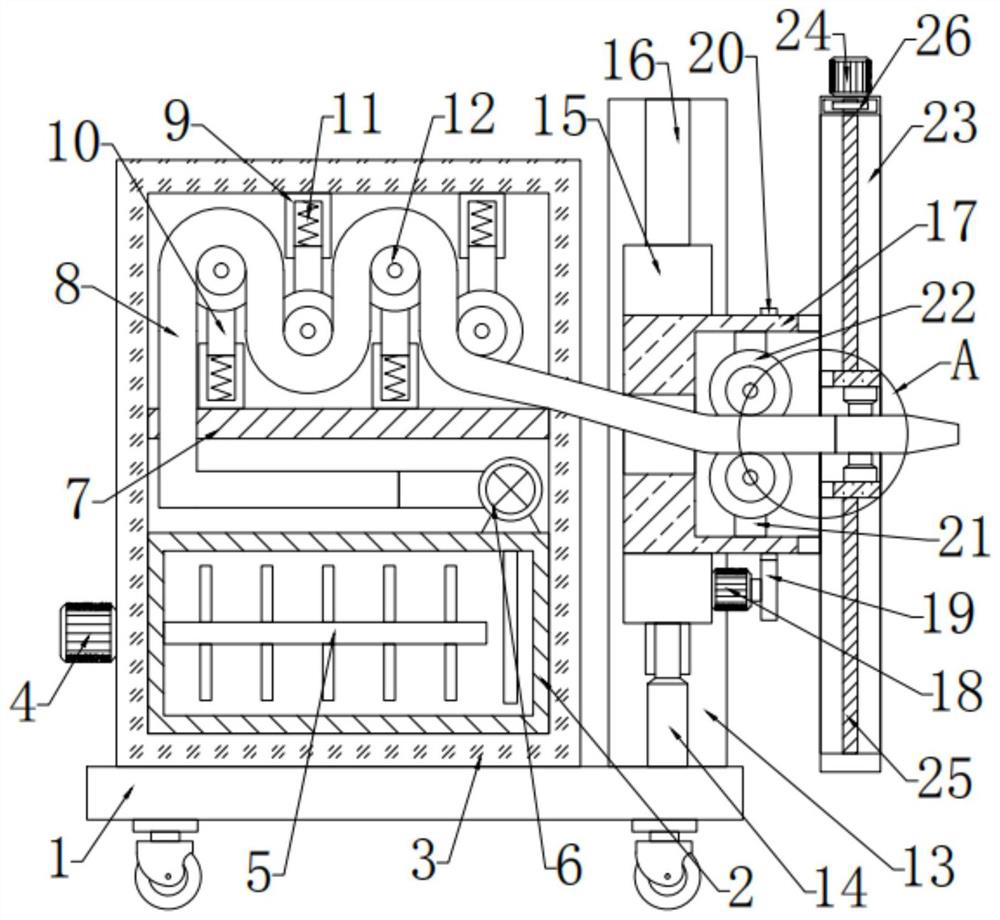

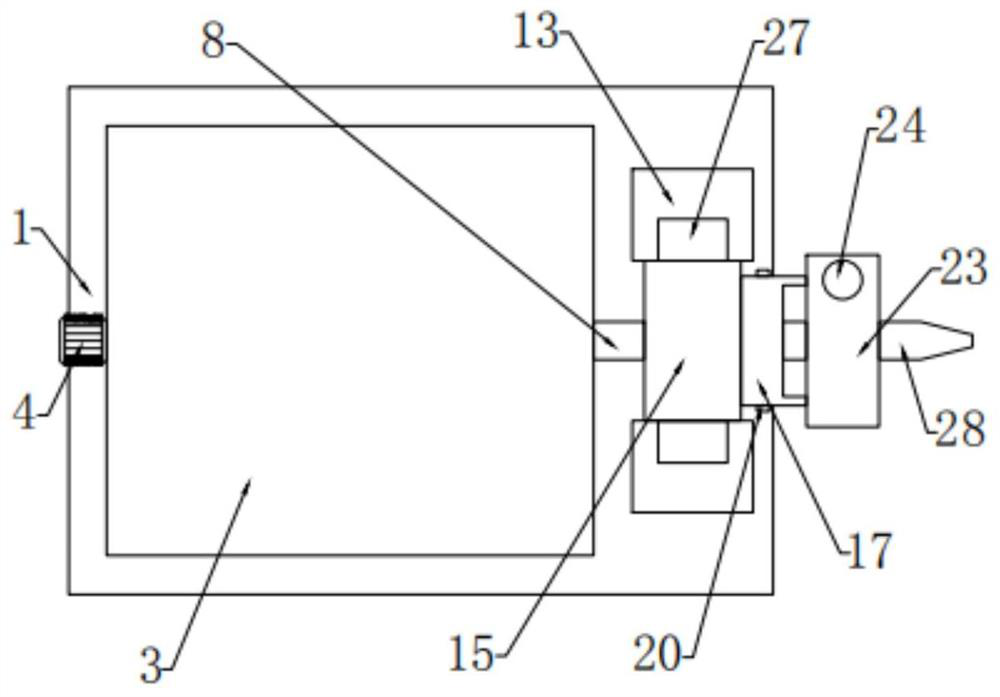

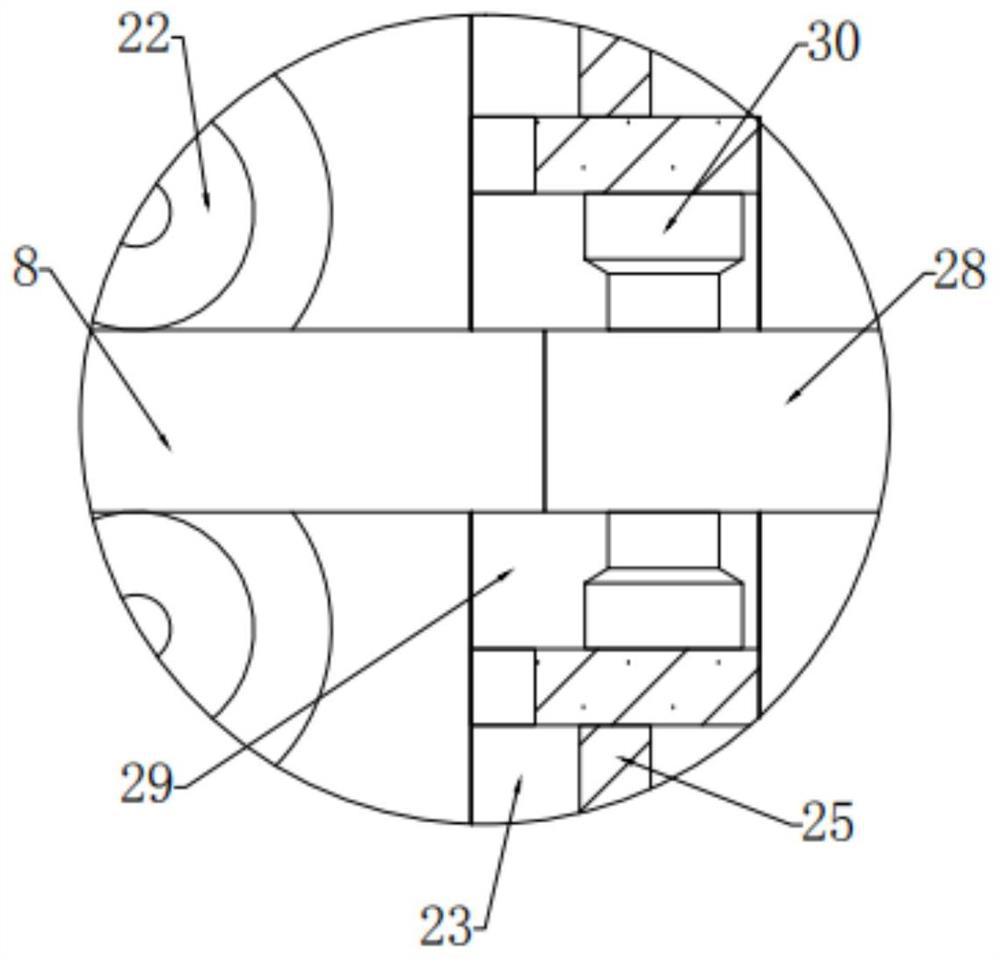

[0025] see Figure 1-4 , in an embodiment of the present invention, a construction gap grouting device includes a base plate 1, a housing 3 is fixedly connected to the top of the base plate 1, and a fixing plate 7 is fixedly connected to the inside of the housing 3, and the fixing plate 7 The lower side is provided with a material storage mechanism, and the output end of the storage mechanism is connected to the grouting head 28 arranged on the right side of the housing 3 through the material guide mechanism on the upper side of the fixed plate 7. The outer side of the grouting head 28 is provided with a 1 A fixedly connected support mechanism.

Embodiment 2

[0027] In this embodiment, the material storage mechanism includes a material storage box 2 that is bolted to the inside of the casing 3, and the left side of the storage box 2 is provided with a first motor 4 that is bolted to the casing 3. The output end of a motor 4 is connected to the stirring rod 5 arranged inside the storage box 2, and the top bolt on the right end of the storage box 2 is connected with a grouting pump 6, and the input end of the grouting pump 6 is connected to the storage box 2. The output end of the grouting pump 6 is connected to the material guide mechanism. By setting the material storage mechanism, the first motor 4 is used to drive the stirring rod 5 to rotate to stir the raw materials, so that the slurry and water are evenly mixed to ensure the effectiveness of grouting.

[0028] In this embodiment, the material guide mechanism includes a material guide tube 8, the input end of the material guide tube 8 is connected to the grouting pump 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com