Water source heat pump system based on sewage source

A sewage source heat pump and water source heat pump technology, which is applied in heat pump, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of unit damage, waste of manpower, material and financial resources, instability, etc., and achieve improvement Applicable environment and overall performance, increased utilization efficiency, and easy promotion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

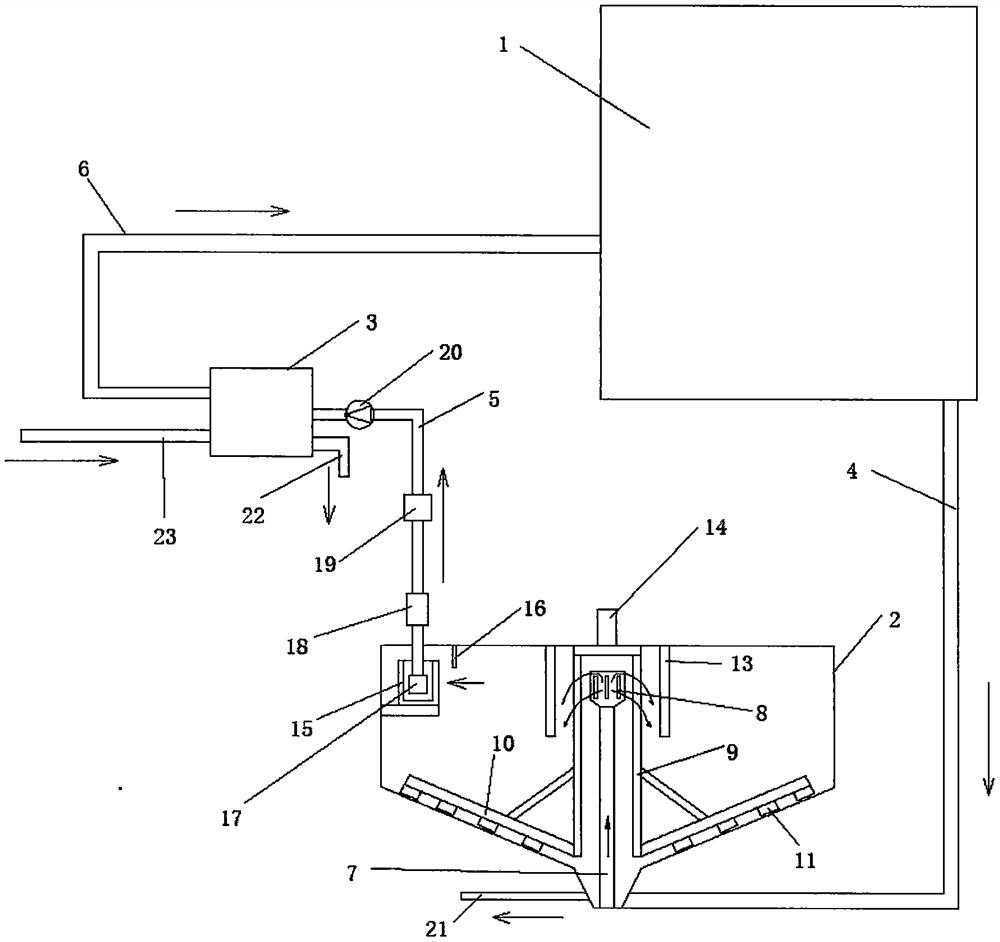

[0023] Please refer to the accompanying drawings of the description. In the embodiment of the present invention, a water source heat pump system based on sewage source includes a factory 1, a sedimentation tank 2, and a sewage source heat pump unit 3. The sewage discharged from the factory 1 passes through the set sewage pipe 4 and The water inlet end of the sedimentation tank 2 is connected, the sewage source heat pump unit 3 is connected with the water outlet end of the sedimentation tank 2 through the connecting pipe 5 provided, the water inlet end of the factory 1 is connected with the water outlet end of the sewage source heat pump unit 3 Connected by the hot water pipe 6 provided.

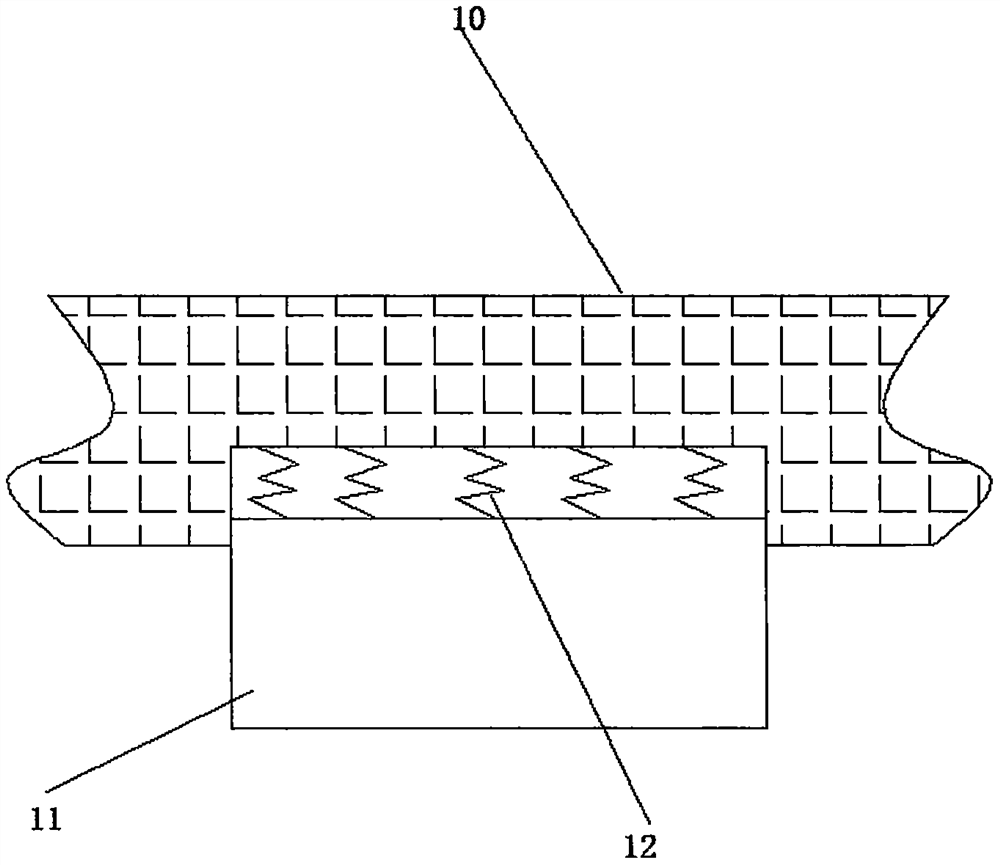

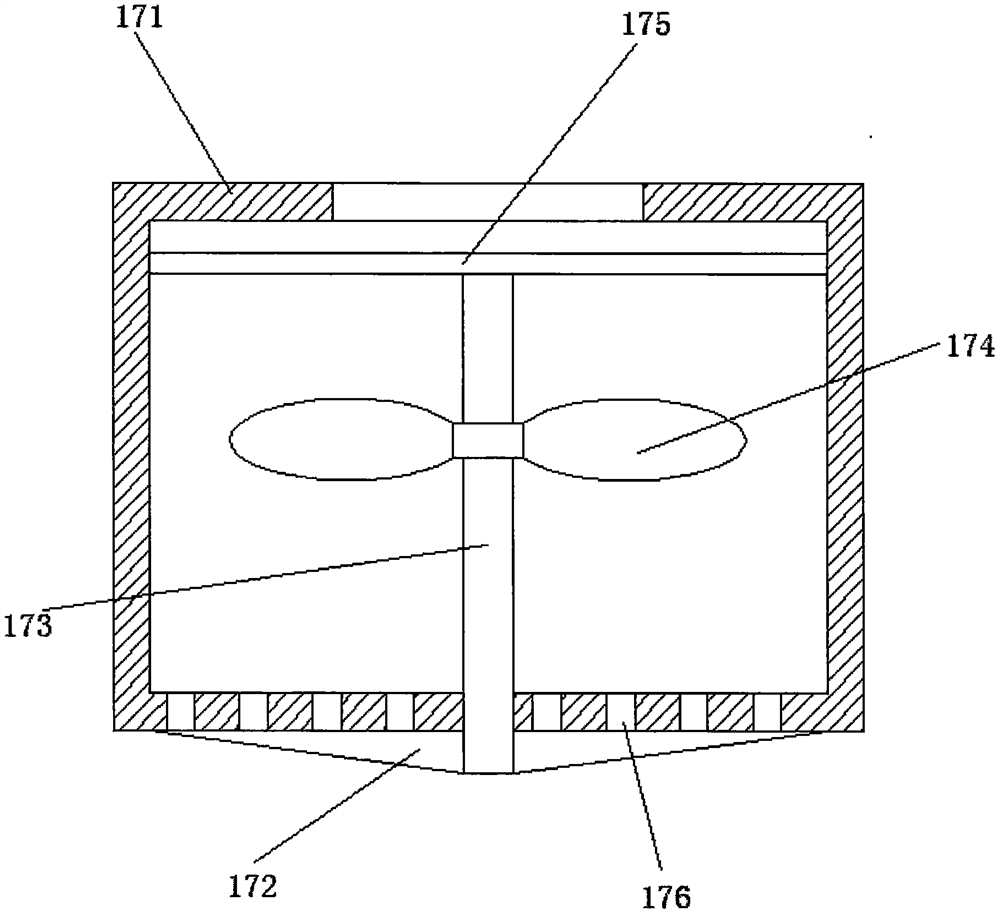

[0024] Furthermore, a standpipe 7 is arranged in the sedimentation tank 2, and the lower end of the standpipe 7 communicates with the sewage pipe 4, and a splitter plate 8 is arranged inside the upper end of the standpipe 7. A scraper frame 9 is installed, and the lower end of the scraper fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap