A Part Quality Inspection Method Based on Point Measurement Data

A quality inspection method and data measurement technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to accurately and comprehensively evaluate the quality characteristics of parts, user losses, etc., achieve objective and true inspection results, and reduce hidden dangers of area omissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions for realizing the object of the present invention are further described below through several specific examples. It should be noted that the technical solutions claimed in the present invention include but are not limited to the following examples.

[0044] The present embodiment provides a part quality detection method based on point measurement data, comprising the following steps:

[0045] Step 1. Discrete processing of surface features

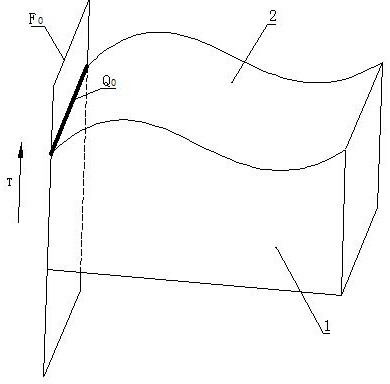

[0046] (1) Refer to figure 1 , with the help of the surface feature discretization tool developed by CATIA, the boundary curve Q of the measured surface in part 1 is obtained 0 ;

[0047] (2) Clear the normal vector T, through Q 0 Construct a surface F parallel to the normal vector T 0 ;

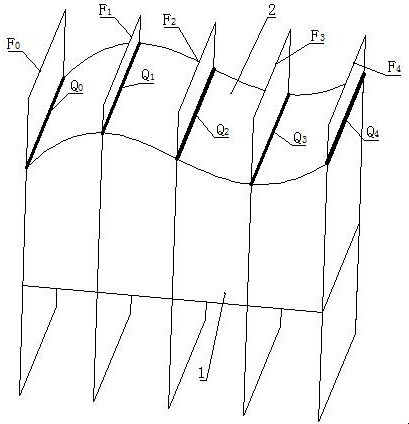

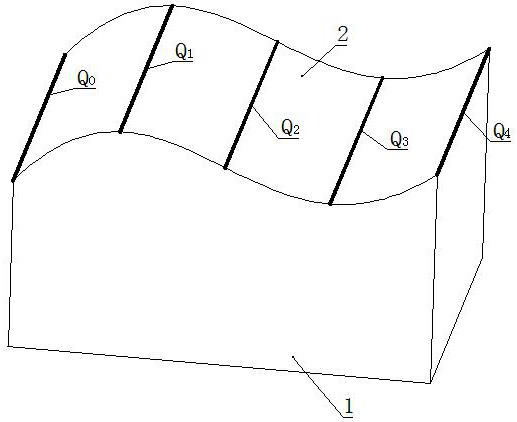

[0048] (3) Refer to figure 2 , image 3 , using CATIA’s surface isometric algorithm, set the isometric parameter n=4, and use F 0 As template surfaces, generate 5 surfaces:

[0049] f 0 , F 1 , F 2 , F 3 , F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com