A gob paste filling slurry and preparation method thereof

A technology of paste filling and goaf, which is applied in the field of paste filling slurry and its preparation in mining areas, which can solve the problems of failure to meet the requirements of working conditions, limited ability of slurry to support the goaf, and slow drying of sand and gravel. , to achieve the effect of accelerating the drying speed, facilitating recovery and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

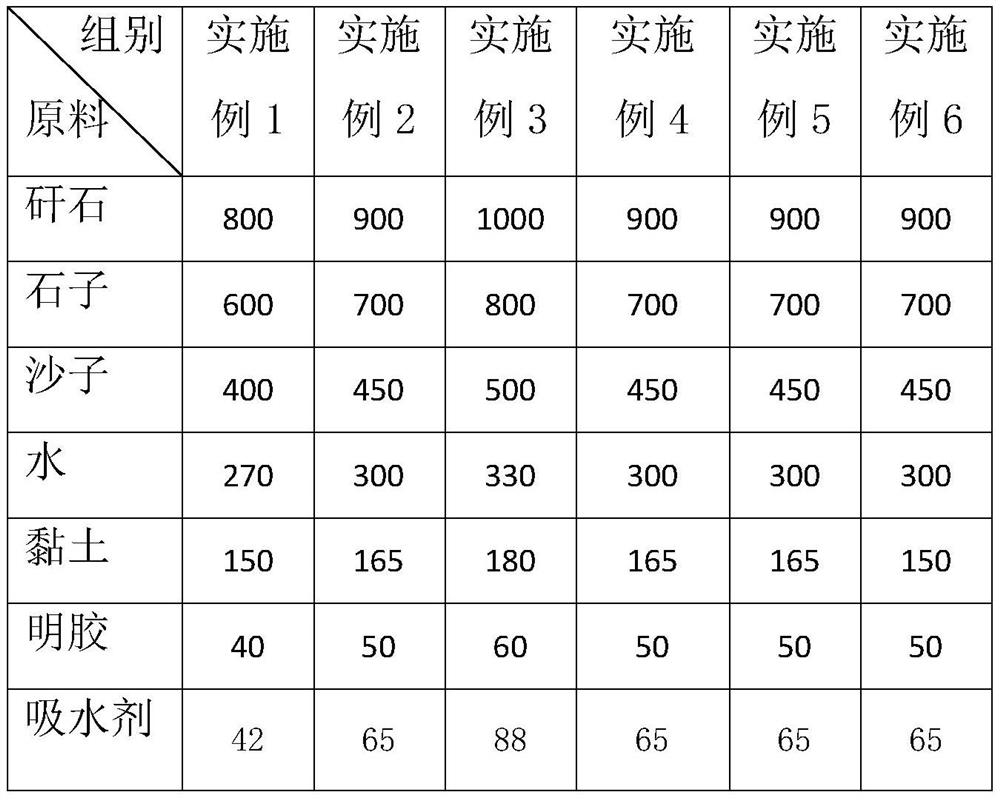

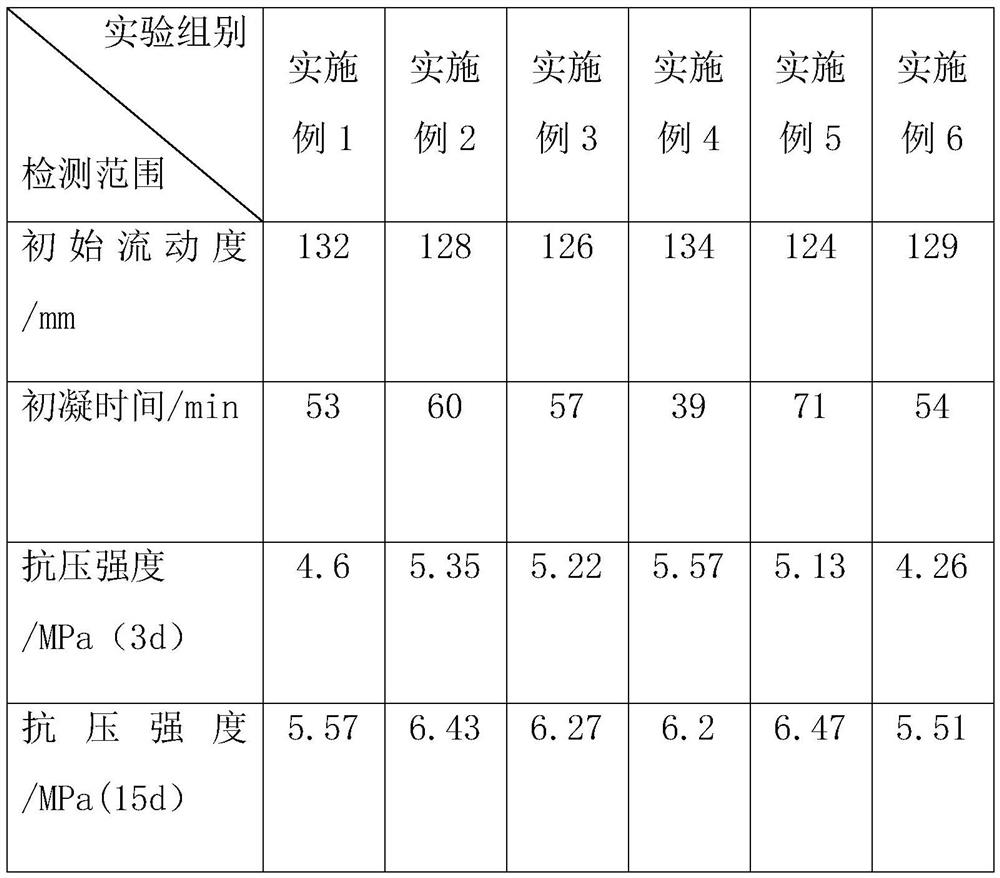

Examples

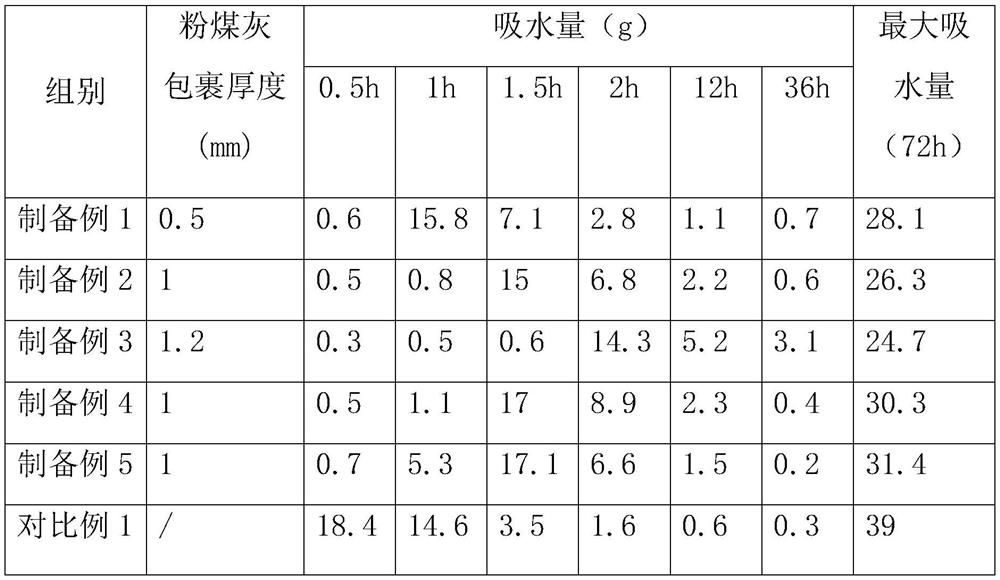

preparation example

[0058] The water-absorbent resin in this preparation example was purchased from the super absorbent resin SAP of Shenyang Keystone Ssangyong Chemical Co., Ltd.

[0059] The hot-melt adhesive can choose XT-610 low-temperature hot-melt adhesive from Dongguan Yimeiduo Thermal Transfer Material Co., Ltd.

preparation example 1

[0061] Select a water-absorbing resin with a particle size of 9mm and a maximum water-absorbing weight of 3900% of its own weight.

[0062] The fly ash with a particle size of 250 μm and a maximum water absorption weight of 90% of its own weight is selected.

[0063] In parts by weight, 12 parts of fly ash are wrapped on the surface of 30 parts of water-absorbing resin.

[0064] Specific operations include:

[0065] Step 1, coating of fly ash, weighing 24 parts by weight of fly ash and heating to 120°C, then pouring 30 parts of water-absorbing resin into the hot fly ash at room temperature, stirring at room temperature and letting it cool naturally Cooling, the stirring speed is 20r / min, and stirring for 15min, so that the fly ash is coated on the surface of the water-absorbing resin to form primary water-absorbing agent particles;

[0066] Step 2, the treatment of the thickened layer of fly ash, heating the primary water-absorbing agent particles to 85°C, spraying hot-melt ...

preparation example 2

[0069] Select a water-absorbing resin with a particle size of 14mm and a maximum water-absorbing weight of 3900% of its own weight.

[0070] The fly ash with a particle size of 250 μm and a maximum water absorption weight of 90% of its own weight is selected.

[0071] Wrap 15 parts of fly ash on the surface of 30 parts of water-absorbent resin.

[0072] Specific operations include:

[0073] Step 1, coating of fly ash, weighing 30 parts by weight of fly ash and heating to 120°C, then pouring 30 parts of water-absorbing resin into the hot fly ash at room temperature, stirring at room temperature and letting it cool naturally Cooling, the stirring speed is 25r / min, and stirring for 20min, so that the fly ash is coated on the surface of the water-absorbing resin to form primary water-absorbing agent particles;

[0074] Step 2, the treatment of the thickened layer of fly ash, heating the primary water-absorbing agent particles to 85°C, spraying hot-melt adhesive on the surface, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com