Dustproof equipment for mine area environment treatment

A technology of environmental governance and dust-proof equipment, which is applied in the direction of dust removal, wellbore/well parts, earthwork drilling and mining, etc., can solve the problems of long working hours and low efficiency, improve efficiency, reduce equipment costs, and shorten the cleaning time the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

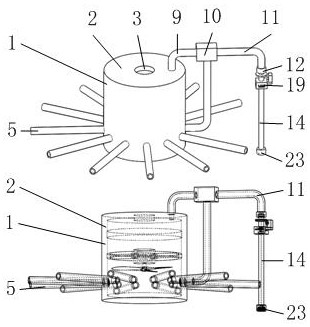

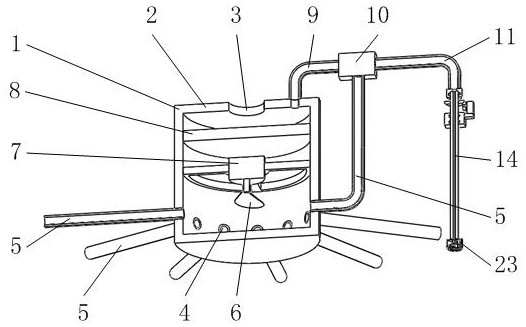

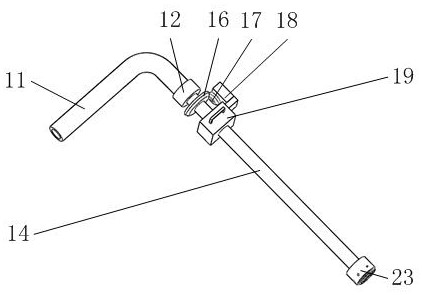

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0036] Such as figure 1 , 2 , 6, it includes dust collection equipment 1, reversing air valve 10, conduit 14, rotating sleeve 19, electric drive module B18, cylindrical shell 23, dust suction pipe B27, spring A28, fixed block 33, slider 38, Scroll sheet 48, wherein as figure 1 , 2 As shown, a dust suction pipe A5 of the dust collection equipment 1 is connected with the ventilation pipe 11 and the exhaust pipe 9 installed on the top of the dust collection equipment 1 through the reversing air valve 10, and the passage formed by the exhaust pipe 9 and the ventilation pipe 11 and The passage formed by the dust suction pipe and the ventilation pipe 11 is switched by the reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com