Film tearing machine for recycling aluminum alloy profiles

A technology of aluminum alloy profiles and film machines, applied in the field of film tearing machines, can solve the problems of increased adhesion of protective films, suction, and long storage backlog of waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

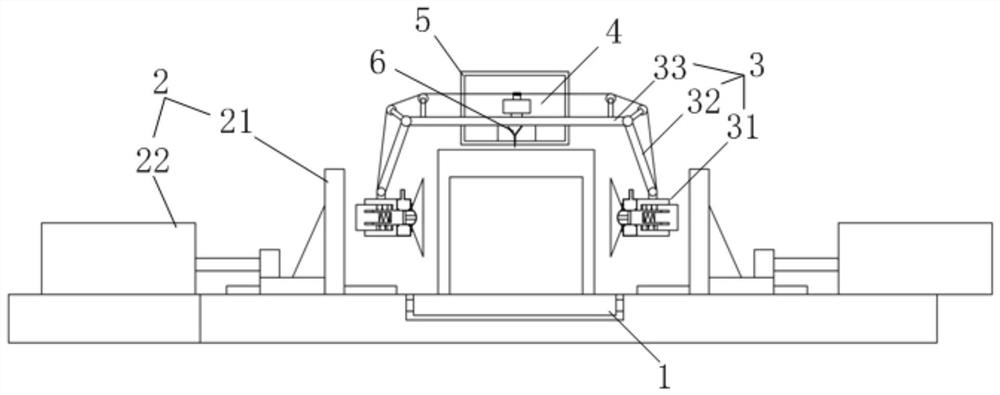

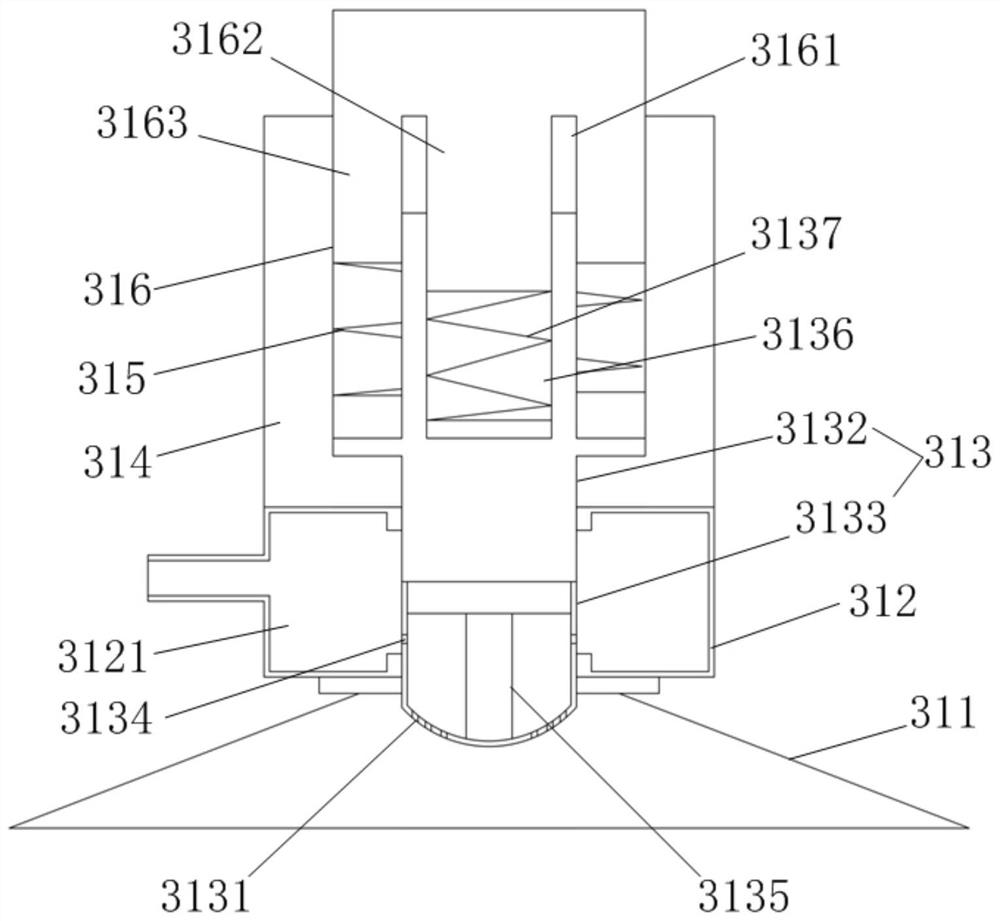

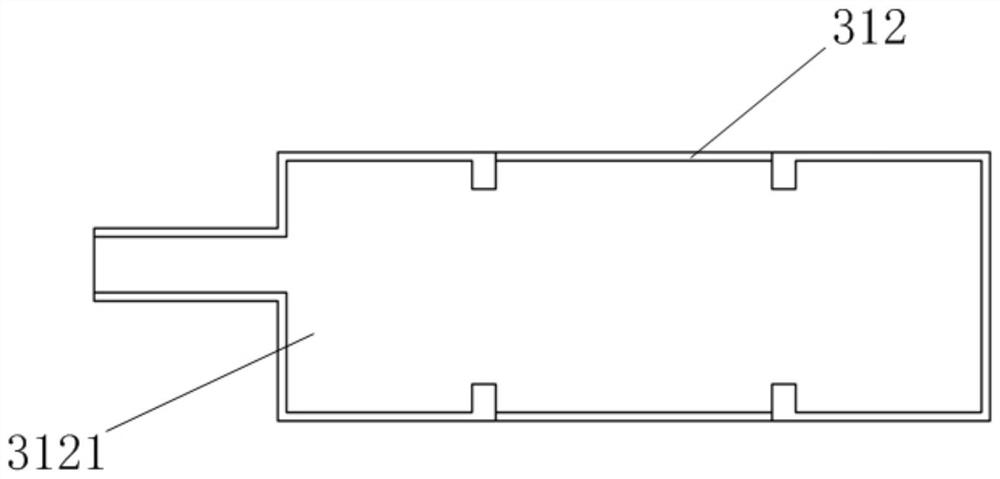

[0035]Seefigure 1 ,2And 3. The present invention provides a film tearing machine for recycling aluminum alloy profiles, comprising a transport device 1, a film taking device and a side pressure device 2 arranged above the transport device; the film taking device includes a device for lifting The film lifting jaws 3 on both sides of the product and the driving device 4 for controlling the opening and closing of the film lifting jaws; the film lifting jaws include a film taking head 31 for sucking the film, a swing arm 32 and a connecting Rod 33, the film taking head 31 is connected to both sides of the connecting rod 33 through the swing arm 32, and the side pressing device 2 is correspondingly provided on one side of the film taking head 31 to hold the film taking head 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com