A grinding wheel morphology with split design, its diamond grinding wheel and its preparation process

A diamond and grinding wheel technology, used in metal processing equipment, grinding/polishing equipment, grinding devices, etc., can solve problems such as solder accumulation, achieve fast heat dissipation, prevent excessive flow, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

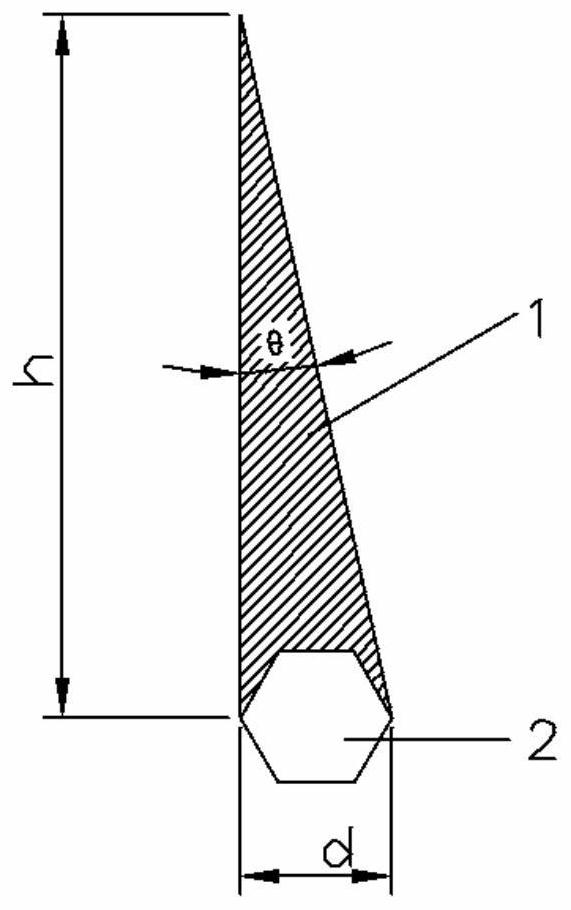

[0055] A diamond mill of 300 mm, a thickness of 25 mm is prepared, and the diamond is 30 / 40 mesh for polishing the casting.

Embodiment 2

[0059] A diamond mill of 400 mm, a thickness of 40 mm is prepared, and the diamond is 30 / 40 mesh for polishing the casting.

[0060] Embodiment: Because the thickness of the grinding wheel is 40 mm, the solder used is a commercial nickel-based alloy solder having a grade BNI2, and its wetting angle is 1 °, and the maximum thickness of the solder does not flow according to the formula:

[0061] D / tan θ = 0.5 / tan1 ° = 28.7mm, the thickness of the grinding wheel is greater than the maximum no current thickness, and therefore, segmentation is required. Since the 28.7 image 3 Distant; dividing line width of 2.5 mm.

[0062] The solder flow is uniform when the diamond mill is brazed.

Embodiment 3

[0064] A diamond grinding wheel with an outer diameter of 300 mm, a thickness of 150 mm, and the diamond is 30 / 40 mesh for polishing the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com