Combined machining workbench

A machining and workbench technology, applied in the field of combined machining workbenches, can solve the problems that the workbench cannot be raised and lowered to adjust the height, and the stability of the roller support is poor, so as to reduce shaking, improve work efficiency, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

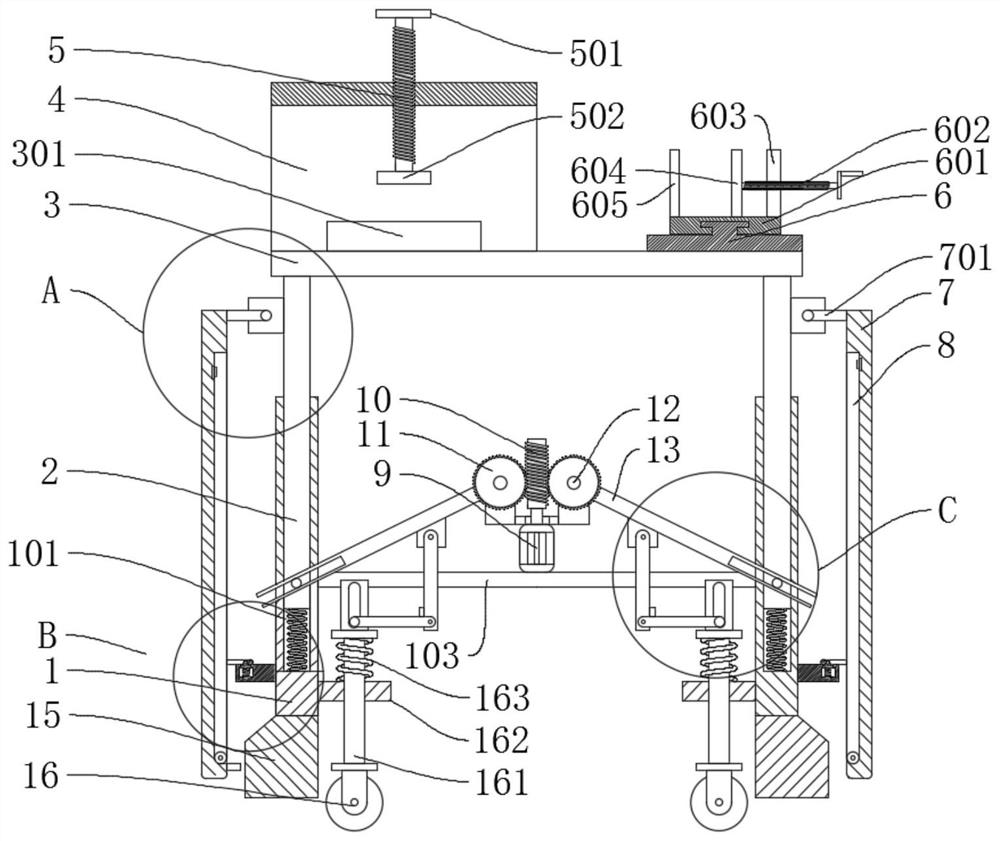

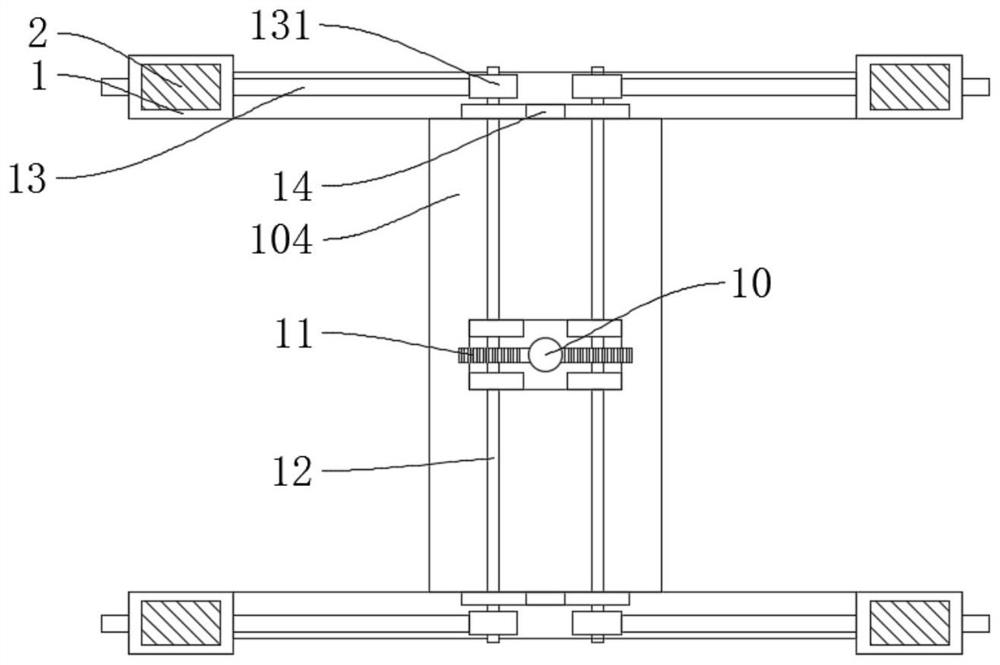

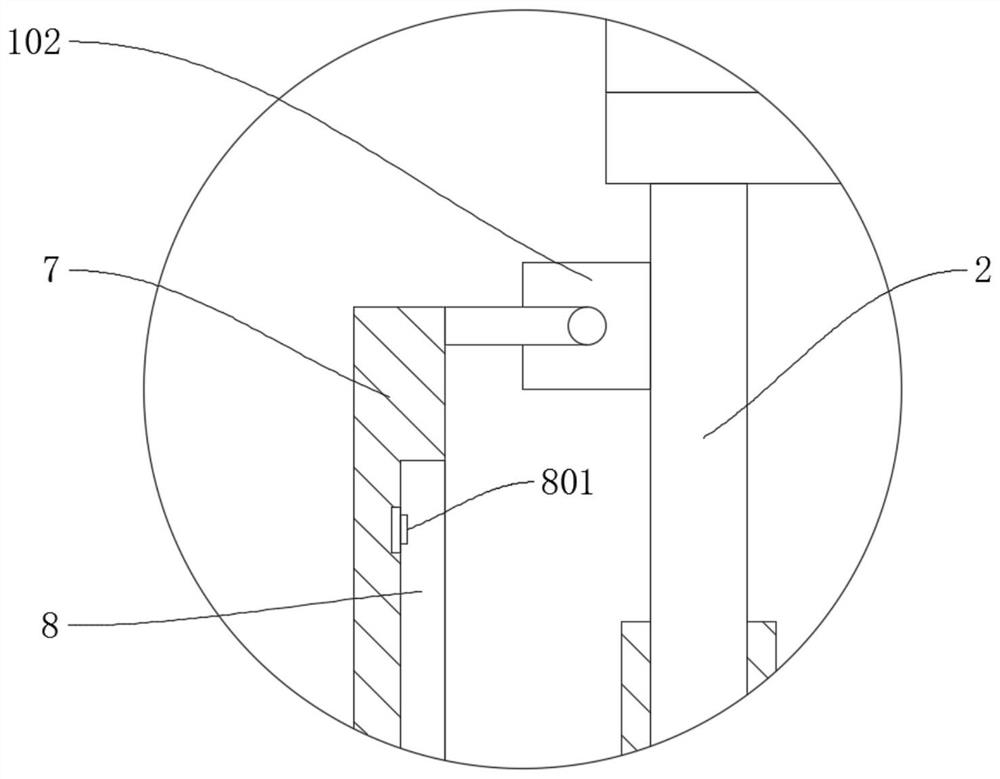

[0032] refer to Figure 1-7, a combined mechanical processing workbench, including a support rod 1, a motor 9, a connecting rod 12, a pressing mechanism and a clamping mechanism. There is a first slide bar 2, the first slide bar 2 is fixedly connected with a table top 3, both the pressing mechanism and the clamping mechanism are fixedly connected with the table top 3, the output end of the motor 9 is fixedly connected with a threaded rod 10, and the connecting rod 12 is fixed A gear 11 and a second rotary sleeve 131 are connected, the gear 11 is meshed with the threaded rod 10, the second rotary sleeve 131 is fixedly connected with a rocker 13, the rocker 13 is slidably connected with the first slide bar 2, and the rocker 13 is fixed Connected with card base 132, the card base 132 is rotatably connected with the first swing rod 18, and the end of the first swing rod 18 away from the card base 132 is rotatably connected with the second swing rod 19, and the second swing rod 19 ...

Embodiment 2

[0044] refer to Figure 1-7 , a combined mechanical processing workbench, including a support rod 1, a motor 9, a connecting rod 12, a pressing mechanism and a clamping mechanism. There is a first slide bar 2, the first slide bar 2 is fixedly connected with a table top 3, both the pressing mechanism and the clamping mechanism are fixedly connected with the table top 3, the output end of the motor 9 is fixedly connected with a threaded rod 10, and the connecting rod 12 is fixed A gear 11 and a second rotary sleeve 131 are connected, the gear 11 is meshed with the threaded rod 10, the second rotary sleeve 131 is fixedly connected with a rocker 13, the rocker 13 is slidably connected with the first slide bar 2, and the rocker 13 is fixed Connected with card base 132, the card base 132 is rotatably connected with the first swing rod 18, and the end of the first swing rod 18 away from the card base 132 is rotatably connected with the second swing rod 19, and the second swing rod 19...

Embodiment 3

[0056] refer to Figure 1-7 , a combined mechanical processing workbench, including a support rod 1, a motor 9, a connecting rod 12, a pressing mechanism and a clamping mechanism. There is a first slide bar 2, the first slide bar 2 is fixedly connected with a table top 3, both the pressing mechanism and the clamping mechanism are fixedly connected with the table top 3, the output end of the motor 9 is fixedly connected with a threaded rod 10, and the connecting rod 12 is fixed A gear 11 and a second rotary sleeve 131 are connected, the gear 11 is meshed with the threaded rod 10, the second rotary sleeve 131 is fixedly connected with a rocker 13, the rocker 13 is slidably connected with the first slide bar 2, and the rocker 13 is fixed Connected with card base 132, the card base 132 is rotatably connected with the first swing rod 18, and the end of the first swing rod 18 away from the card base 132 is rotatably connected with the second swing rod 19, and the second swing rod 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com