Waste tire pretreatment equipment

A waste tire and pretreatment technology, applied in metal processing, etc., can solve the problems of insufficient heating and heating efficiency to be improved, and achieve the effects of improving heating efficiency, shortening heating time, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

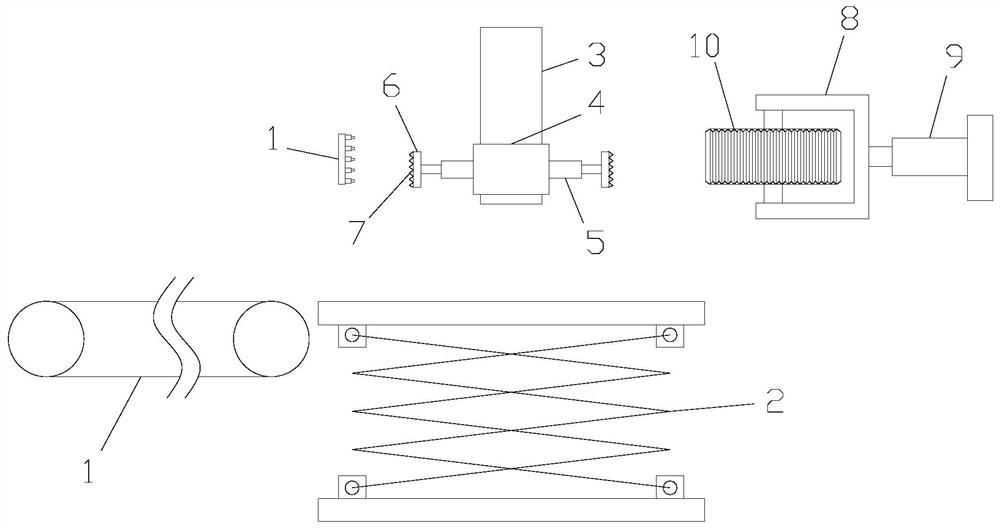

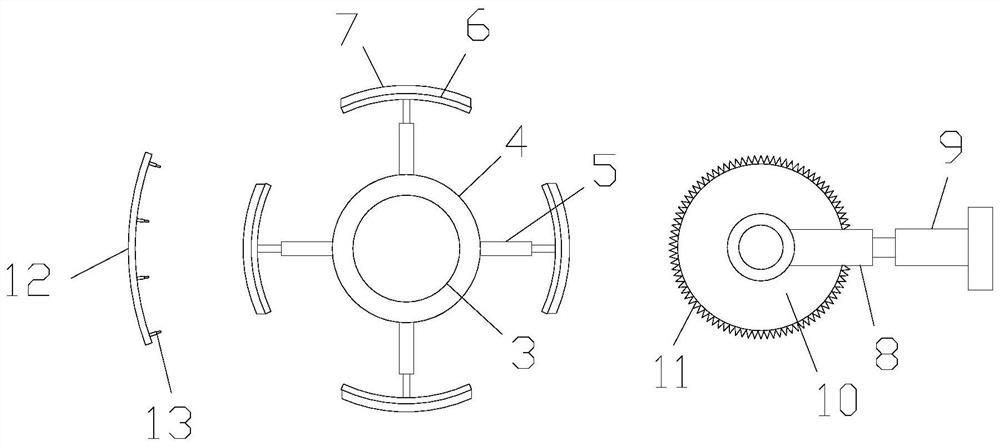

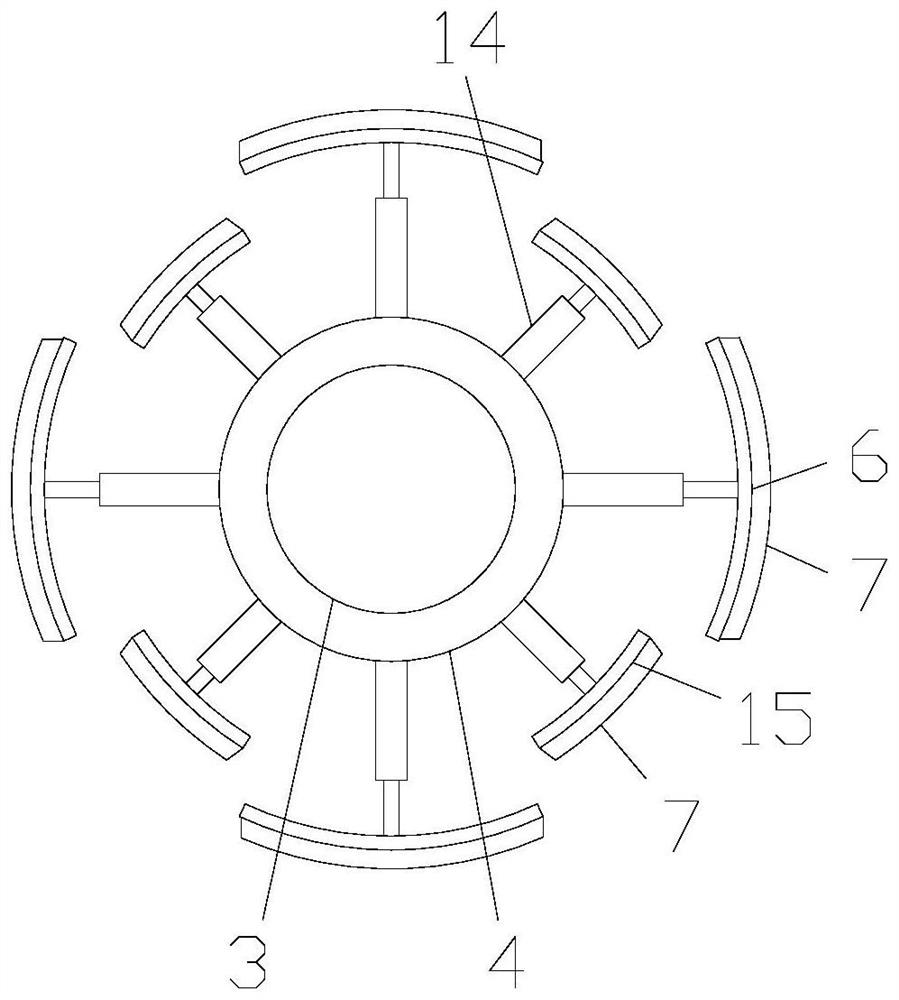

[0041] As an optional implementation, the cutting assembly includes

[0042] Mounting bracket 8;

[0043] a driving member 9, connected to the mounting bracket 8;

[0044] The cutting roller 10 is rotatably mounted on the mounting bracket 8 , and a plurality of first cutting blades 11 are arranged on the roller surface of the cutting roller 10 .

[0045] Optionally, the driving member 9 is a telescopic rod driven by hydraulic pressure or electricity.

[0046] In this way, after the fixing mechanism fixes the waste tire, the driving member 9 drives the mounting bracket 8 to move, so that part of the first cutting blade 11 of the cutting roller 10 abuts against the outer wall of the waste tire, and then drives the cutting roller 10 to rotate, so that The first cutting blade 11 can cut grooves on the entire outer wall of the waste tire, so as to increase the specific surface area of the tire. In addition, the position of the cutting roller 10 can be adjusted through the sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com